A kind of preparation method of water-packed explosive beads for preformed cigarettes

A pre-formed and explosive bead technology, which is applied in the application, tobacco, e-liquid filter and other directions, can solve the problems that the explosive beads are not easy to be squeezed, cannot be used for production, and have poor practicability, so as to improve the smoking quality and be easy to be squeezed and broken. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation steps:

[0027] 1). Using plastic thermoplastic method, the flexible plastic film is processed into hollow spherical plastic beads. The outer diameter of the hollow spherical plastic beads is 2.6 mm; the thickness of the plastic wall is 0.1 mm.

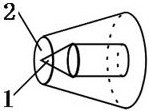

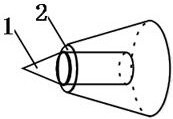

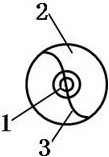

[0028] 2). Use as attached Figure 1-3 The dual injector shown, injects water through the inner injector, while the outer injector simultaneously applies hot melt adhesive at the injection port. After the injection is completed, the hot melt adhesive is used to seal the injection port through the movement of the scraper to play a sealing role.

[0029] 3). Put the sealed spherical particles into a hot air rotary oven. The temperature is 80-90°C, and the wind speed is generally 1m / s to homogenize the hot melt adhesive on the surface of the sphere to produce pop-up beads with good integrity.

[0030] The prepared popping beads are added to the cigarette filter through a conventional process to make a cigarette. W...

Embodiment 2

[0032] Preparation steps:

[0033] 1). Using plastic thermoplastic method, the flexible plastic film is processed into hollow spherical plastic beads. The outer diameter of the hollow spherical plastic beads is 3.8mm; the thickness of the plastic wall is 0.15mm.

[0034] 2). Use as attached Figure 1-3 The dual injector shown, injects water through the inner injector, while the outer injector simultaneously applies hot melt adhesive at the injection port. After the injection is completed, the hot melt adhesive is used to seal the injection port through the movement of the scraper to play a sealing role.

[0035] 3). Put the sealed spherical particles into a hot air rotary oven. The temperature is 80-90°C, and the wind speed is generally 5m / s to homogenize the hot melt adhesive on the surface of the sphere to produce pop-up beads with good integrity.

[0036] The prepared popping beads are added to the cigarette filter through a conventional process to make a cigarette. Wh...

Embodiment 3

[0038] Preparation steps:

[0039] 1). Using plastic thermoplastic method, the flexible plastic film is processed into hollow spherical plastic beads. The outer diameter of the hollow spherical plastic beads is 3.6 mm; the thickness of the plastic wall is 0.13 mm.

[0040] 2). Use as attached Figure 1-3 The dual injector shown, injects water through the inner injector, while the outer injector simultaneously applies hot melt adhesive at the injection port. After the injection is completed, the hot melt adhesive is used to seal the injection port through the movement of the scraper to play a sealing role.

[0041] 3). Put the sealed spherical particles into a hot air rotary oven. The temperature is 80-90°C, and the wind speed is generally 3m / s to homogenize the hot melt adhesive on the surface of the sphere to produce pop-up beads with good integrity.

[0042] The prepared popping beads are added to the cigarette filter through a conventional process to make a cigarette. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com