Mechanical device for truck loading

A technology of a mechanical device and a main body is applied in the field of mechanical devices for loading vehicles, which can solve the problems of poor water replenishment effect, internal water loss, and height drop of loaded goods, so as to avoid waste caused by water flow, reduce water flow consumption, and reduce height drop. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

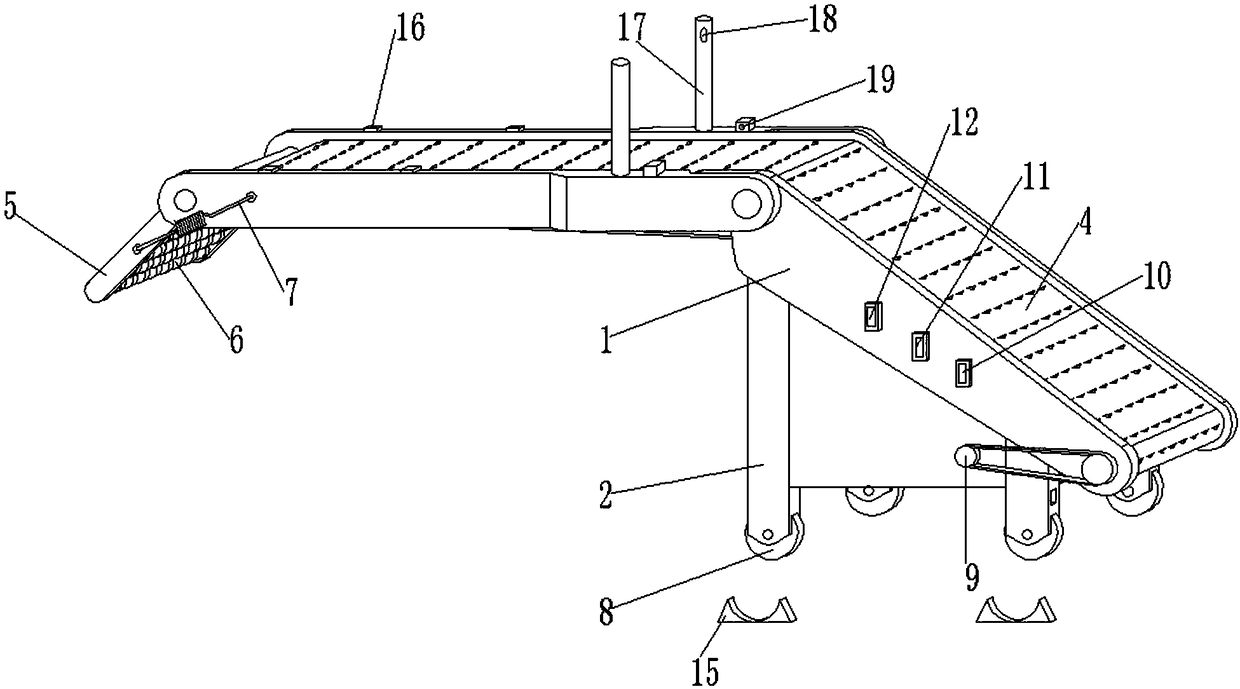

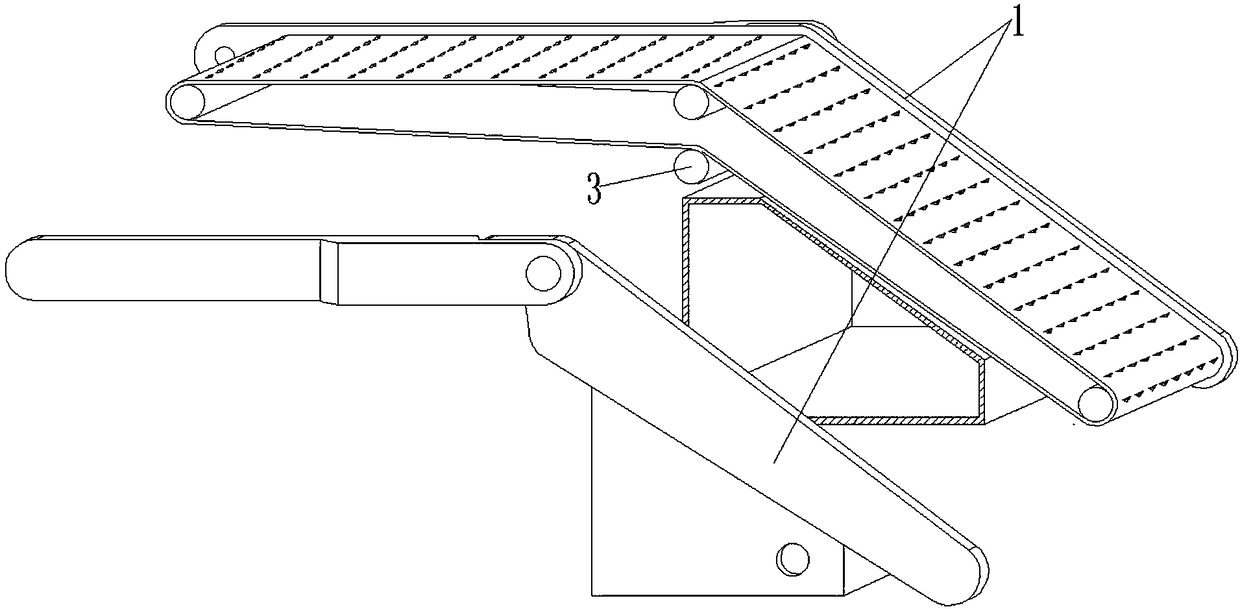

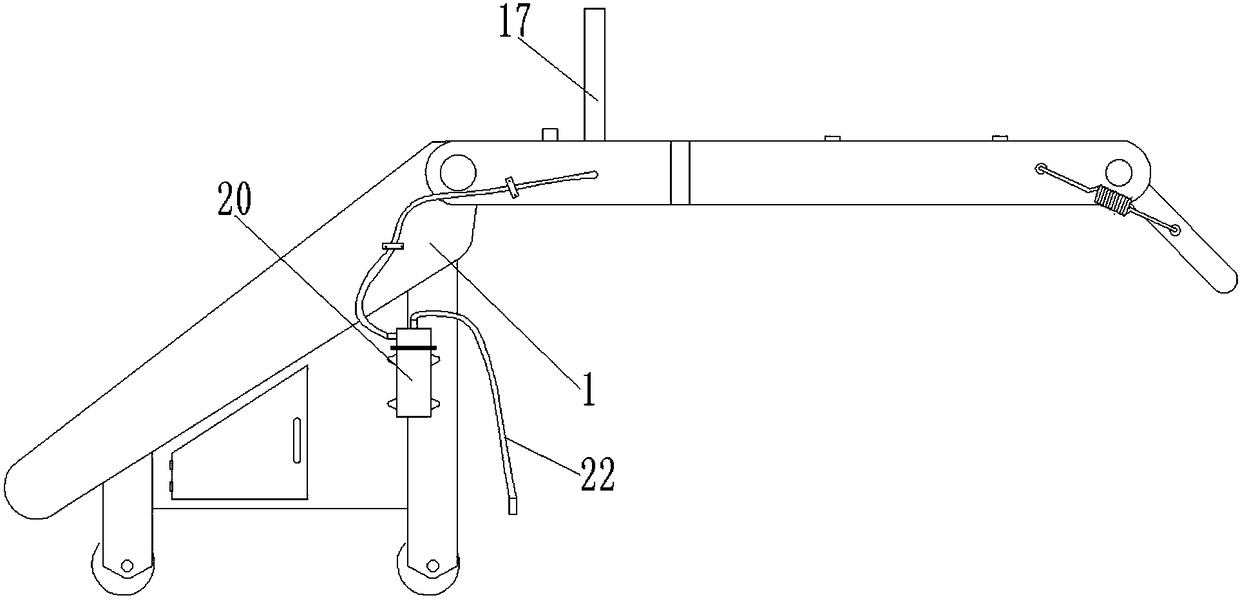

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036]The present invention provides a mechanical device for loading vehicles, including a main body 1, a support frame 2, a rotating shaft 3, a conveyor belt 4, a prismatic rubber block 401, a rotating frame 5, a rotating bead 6, a tension spring 7, a rotating wheel 8, and a driving shaft 9 , conveyor belt running switch 10, lighting switch 11, sprinkler switch 12, battery 13, transmission motor 14, wheel fixing block 15, LED light 16, metal tube 17, atomizing head 18, photoelectric switch 19, water pump 20, controller 21 and Pipeline 22, four supporting frames 2 are installed at the bottom of the main body 1, and the four rotating shafts 3 are rotatably connected in the main body 1, the conveyor belt 4 is rotatably connected in the main body 1, and the rotary frame 5 is rotatably connected with the top front end of the main body 1, so The rotating bead 6 is several places, and the rotating bead 6 and the rotating bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com