Fermenting tank capable of fermenting hot peppers

A technology for fermenting peppers and fermenting tanks, which is applied in the field of fermentation, can solve the problems of inconvenient gas suction, inconvenient gas discharge, and inconvenient pepper stirring, etc., and achieves the effect of preventing itself from falling off and increasing the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

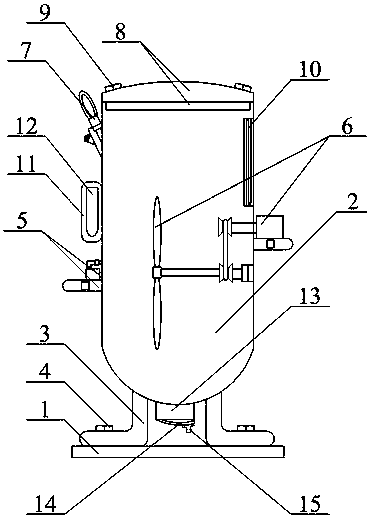

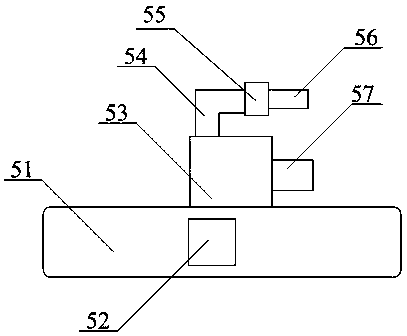

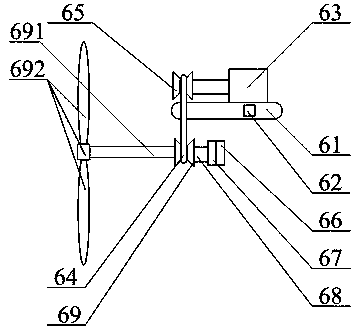

[0041] as attached figure 1 to attach Figure 4 shown

[0042]The present invention provides a fermenter for fermenting peppers, comprising a bottom plate 1, a fermenter 2, a base 3, fastening bolts 4, a vacuum suction pump structure 5, a pepper fermentation mixer structure 6, an inspection vent pipe structure 7, a sealing cover 8, Protective bolt 9, heating pipe 10, stainless steel mounting plate 11, thermometer 12, discharge pipe 13, protective cover 14 and handle 15, one end of the base 3 is respectively welded to the left and right sides of the bottom of the fermenter 2, and the other end passes through The fastening bolt 4 is connected to the top of the base plate 1; the vacuum suction pump structure 5 is installed on the lower left side of the fermenter 2; the pepper fermentation mixer structure 6 is installed in the middle position on the right side of the fermenter 2; The viewing vent pipe structure 7 described above is fixed on the upper left side of the fermenter 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com