Ultralow-temperature online maintenance ball valve

An ultra-low temperature, ball valve technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of ultra-low temperature ball valve safety hazards, difficult online maintenance, harsh working environment, etc., to achieve small operating torque, reliable sealing performance, and production technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

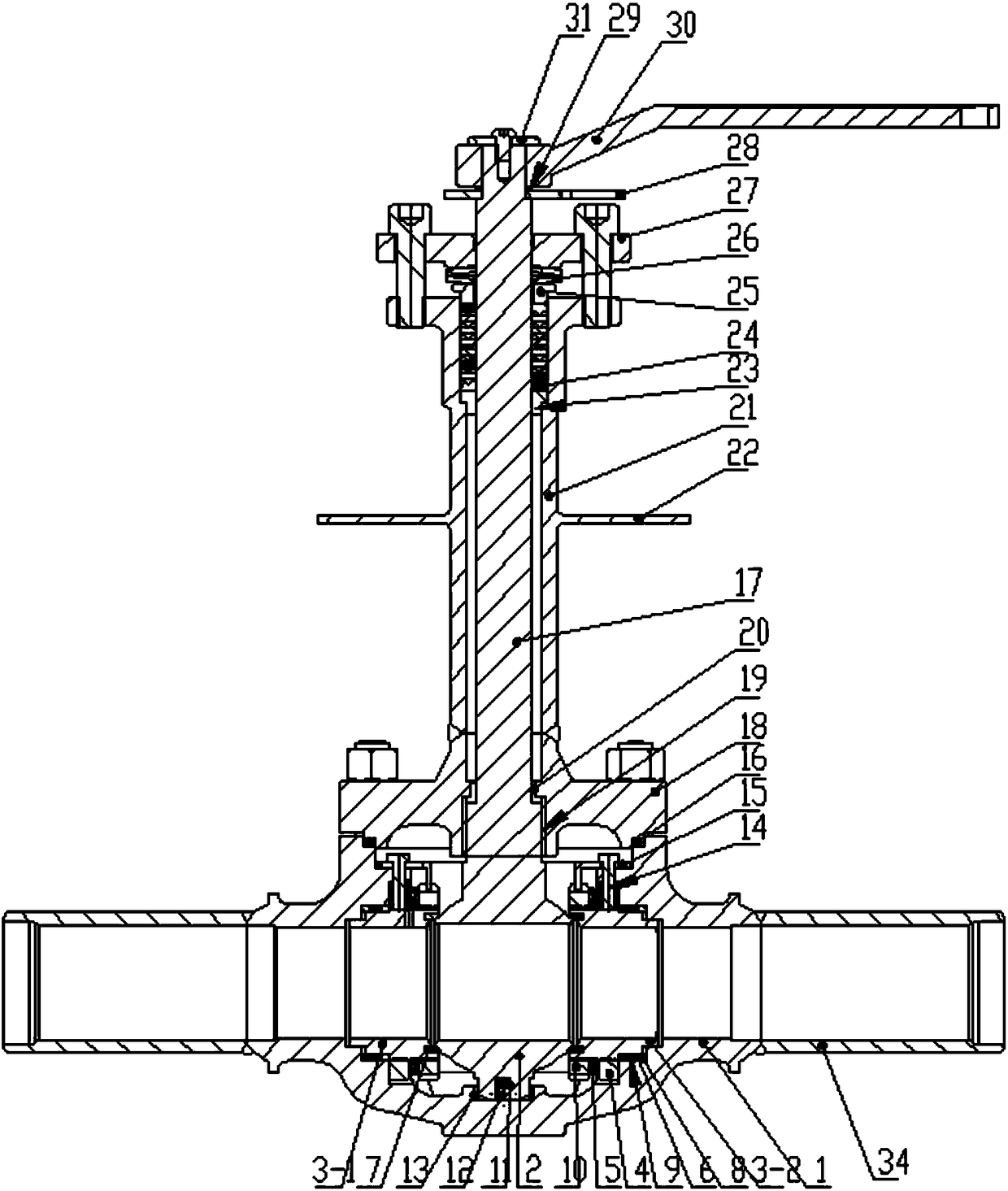

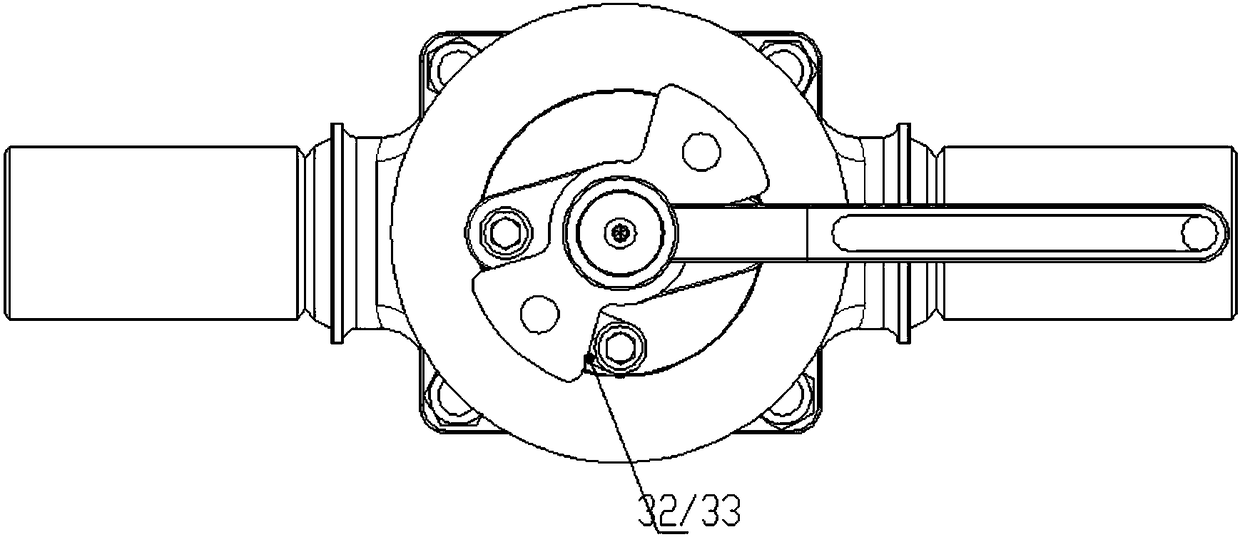

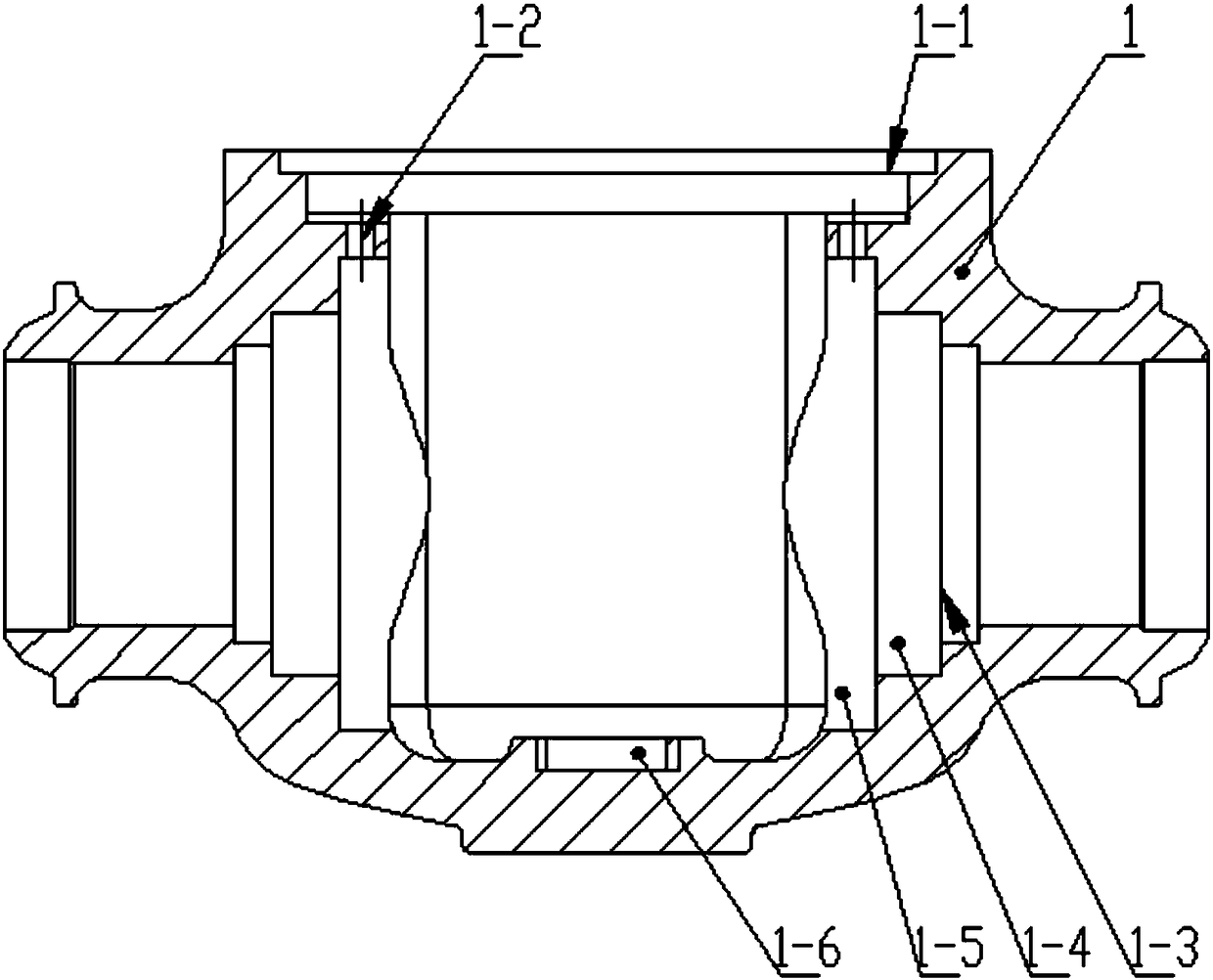

[0024] Such as figure 1 and combine Figure 2 to Figure 5 As shown, an ultra-low temperature online maintenance ball valve includes a valve body 1, a ball 2, a valve stem 17, a valve cover 18, a stuffing box body 21, a handle 30, a left valve seat 3-1 and a right valve seat 3-2, the The valve cover 18 is fixed on the upper end of the valve body by bolts, the stuffing box body is arranged on the upper end of the valve cover 18, the centerline axis of the stuffing box body 21 forms a cavity, and the valve stem 17 is inserted into the cavity, so The left valve seat 3-1 and the right valve seat 3-2 are arranged inside the valve body 1, the ball 2 is clamped between the left valve seat 3-1 and the right valve seat 3-2, and the valve stem 17 The lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com