Oiling device

An oiling device and oiling technology, applied in the direction of lubricating parts, conveying pipes/joints, mechanical equipment, etc., can solve problems such as uneven oiling, and achieve the effect of improving the oiling effect, simplifying the device and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

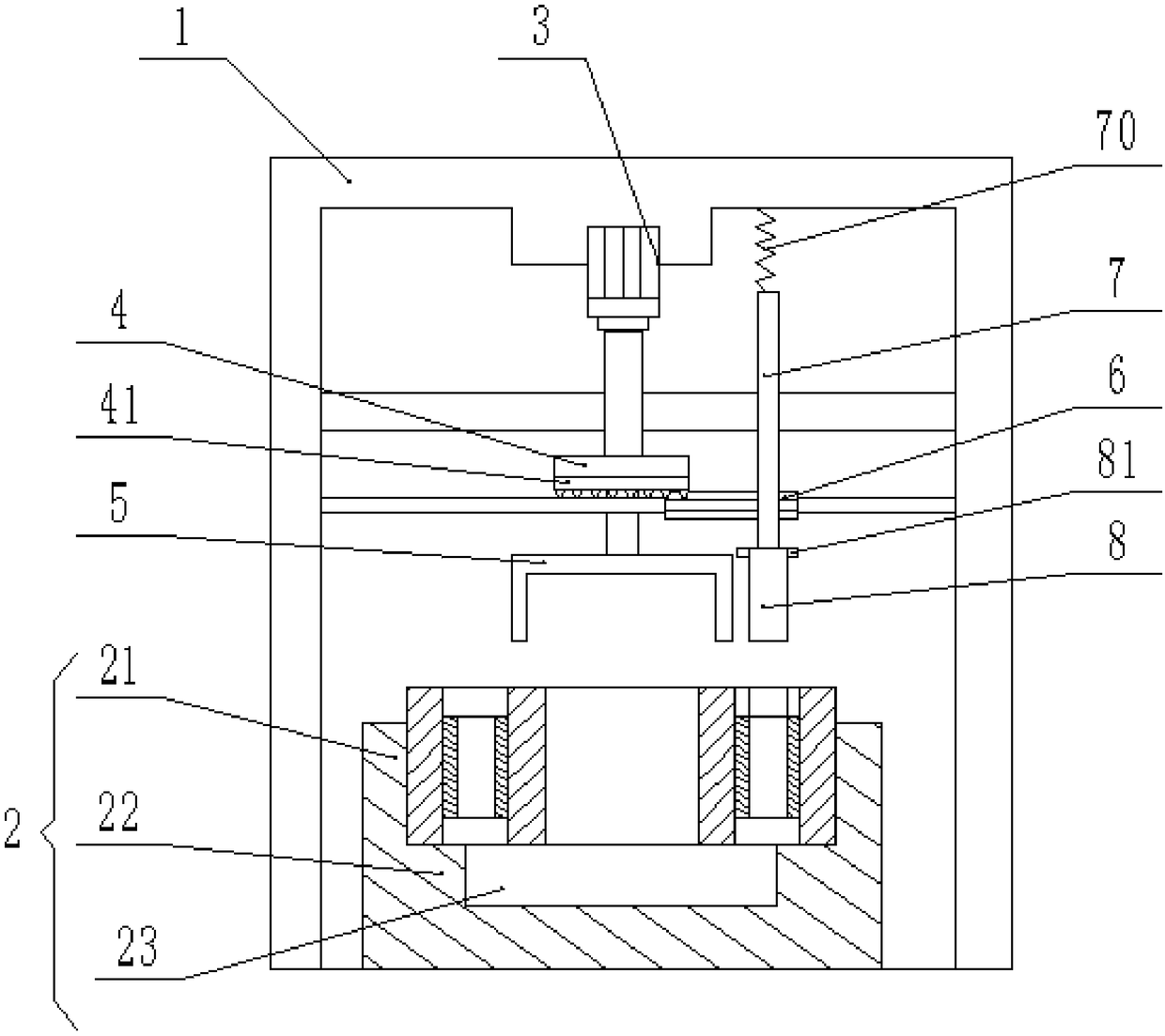

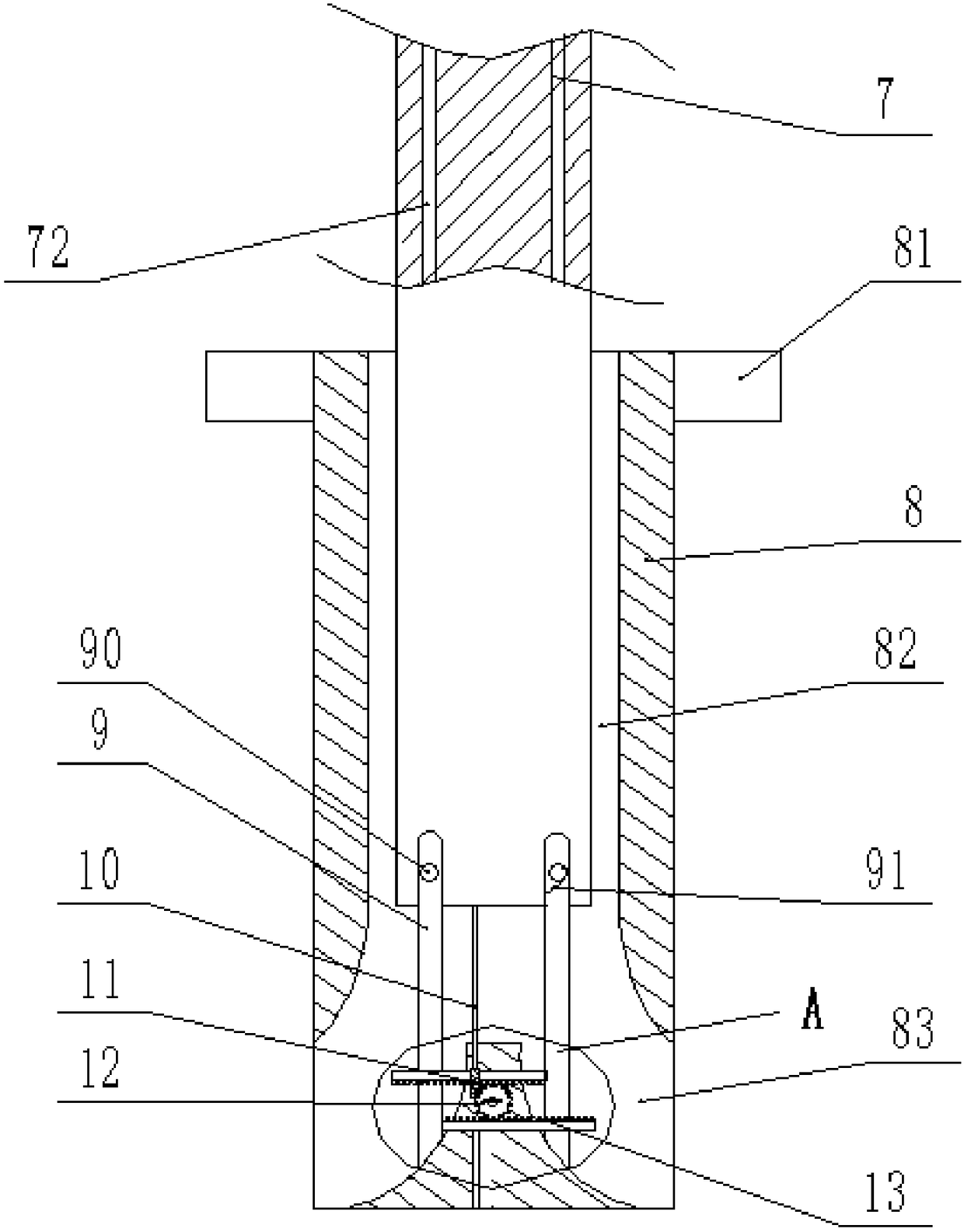

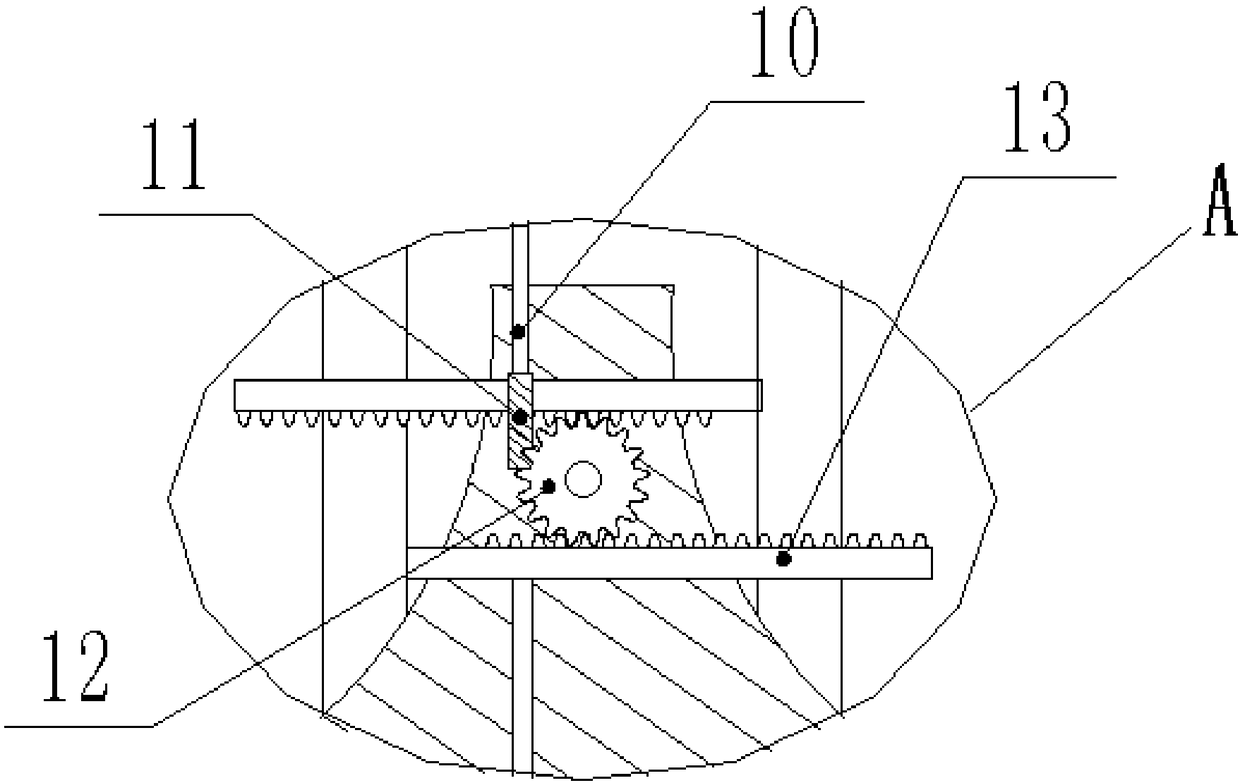

[0018] The reference signs in the drawings of the description include: frame 1, base 2, positioning platform 21, support platform 22, return flow tank 23, motor 3, turntable 4, rack 41, jaw 5, gear 6, push rod 7, Extension spring 70, oil inlet hole 72, positioning sleeve 8, limit block 81, sliding cavity 82, guide groove 83, oiling shaft 9, pin shaft 90, torsion spring 91, oil passage 92, oil outlet hole 93, empty Cavity 94, communication hole 95, main helical rack 10, first helical gear 11, second helical gear 12, slave helical rack 13.

[0019] The embodiment is basically as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 Shown:

[0020] An oiling device, comprising a frame 1, a base 2, a driving part and an oiling part, the base 2 is cylindrical as a whole, the longitudinal section of the base 2 is trapezoidal, and the base 2 includes a posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com