High-precision multi-section sleeve cylinder for pharmaceutical machinery

A high-precision, section-sleeve technology, used in mechanical equipment, servo motor components, fluid pressure actuation system testing, etc., can solve problems such as low precision, inability to solve installation in small spaces, and inability to meet installation and high precision at the same time. achieve the effect of preventing stall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

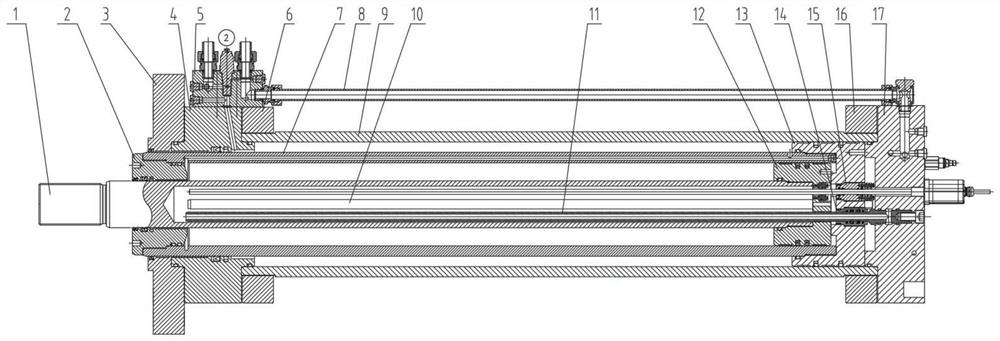

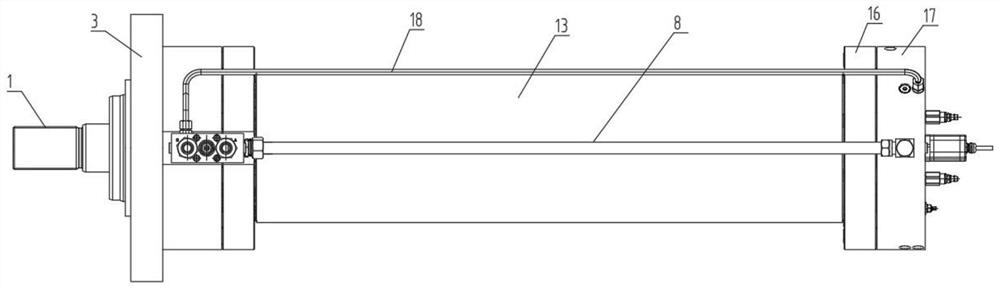

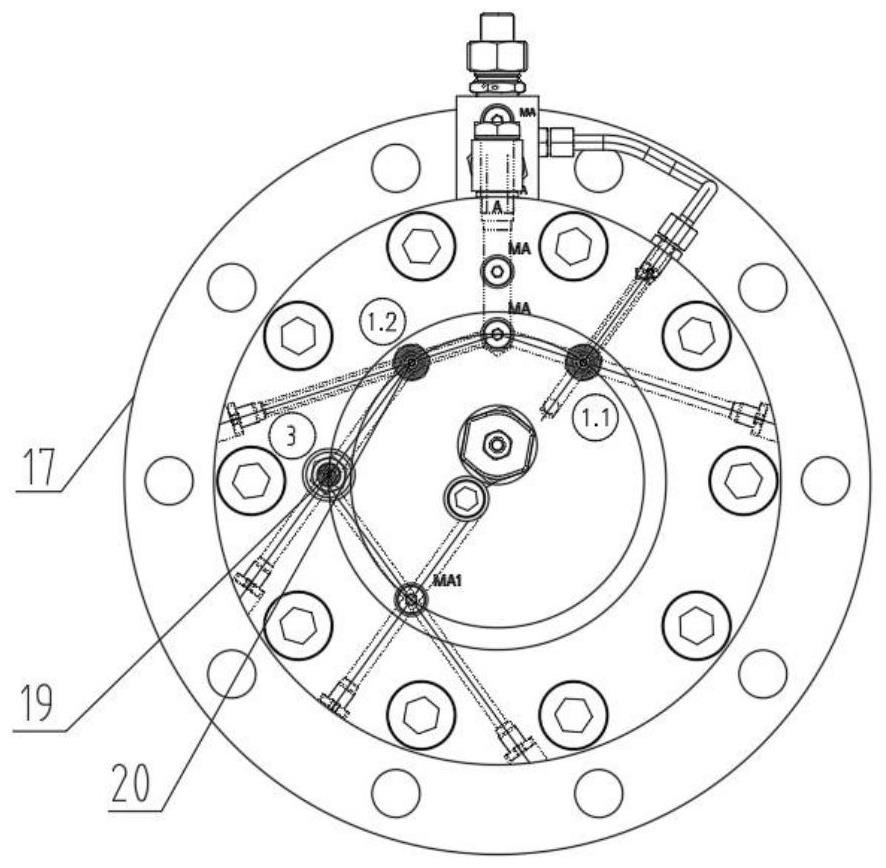

[0033] like figure 1 As shown, a high-precision multi-section sleeve cylinder for pharmaceutical machinery proposed by the present invention includes a large cylinder barrel 9 and a small cylinder barrel 7, and the small cylinder barrel 7 is movably socketed in the large cylinder barrel 9, The ends of the small cylinder barrel 7 and the large cylinder barrel 9 are all provided with end caps, and the small cylinder barrel 7 is provided with an anti-rotation shaft 10, and the anti-rotation shaft 10 and the end caps at the ends constitute Movable limit fit; one end of the anti-rotation shaft 10 is fixedly connected to the piston rod 1; the outer side of the front end cover 4 is fixedly installed with a mounting flange 3, and the outer side of the large cylinder 9 is provided with a telescopic power assembly.

[0034] Specifically, the telescopic power assembly in this embodiment includes:

[0035] A transition block 5, which is connected to the end pipe of the large cylinder bar...

Embodiment 2

[0057] refer to figure 1 and figure 2 , The difference between this embodiment and Embodiment 1 is that this embodiment further includes a displacement sensor for detecting the movement size of the piston rod 1 .

[0058] Specifically, after the transition block 5 is connected to the external hydraulic pressure, when it needs to be stretched out, one of the oil inlets enters the oil, and the piston rod 1 in the small cylinder is stretched out first. When the pressure value reaches the set pressure value of the sequence valve 1.2 , the piston rod 1 in the small cylinder stretches out in place this moment. The displacement sensor can monitor the protruding dimension of the piston rod 1; the displacement sensor detects the protruding dimension of the piston rod 1, thereby improving the accuracy;

[0059] When oil enters the other oil inlet, the piston rod 1 in the large cylinder retracts first. When the pressure value reaches the pressure value 1.1 set by the sequence valve, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com