OGS capacitive touch screen and production method thereof

A technology of a capacitive touch screen and a manufacturing method, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve problems such as no mainstream structure of capacitive screens, and achieve the effect of reducing investment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

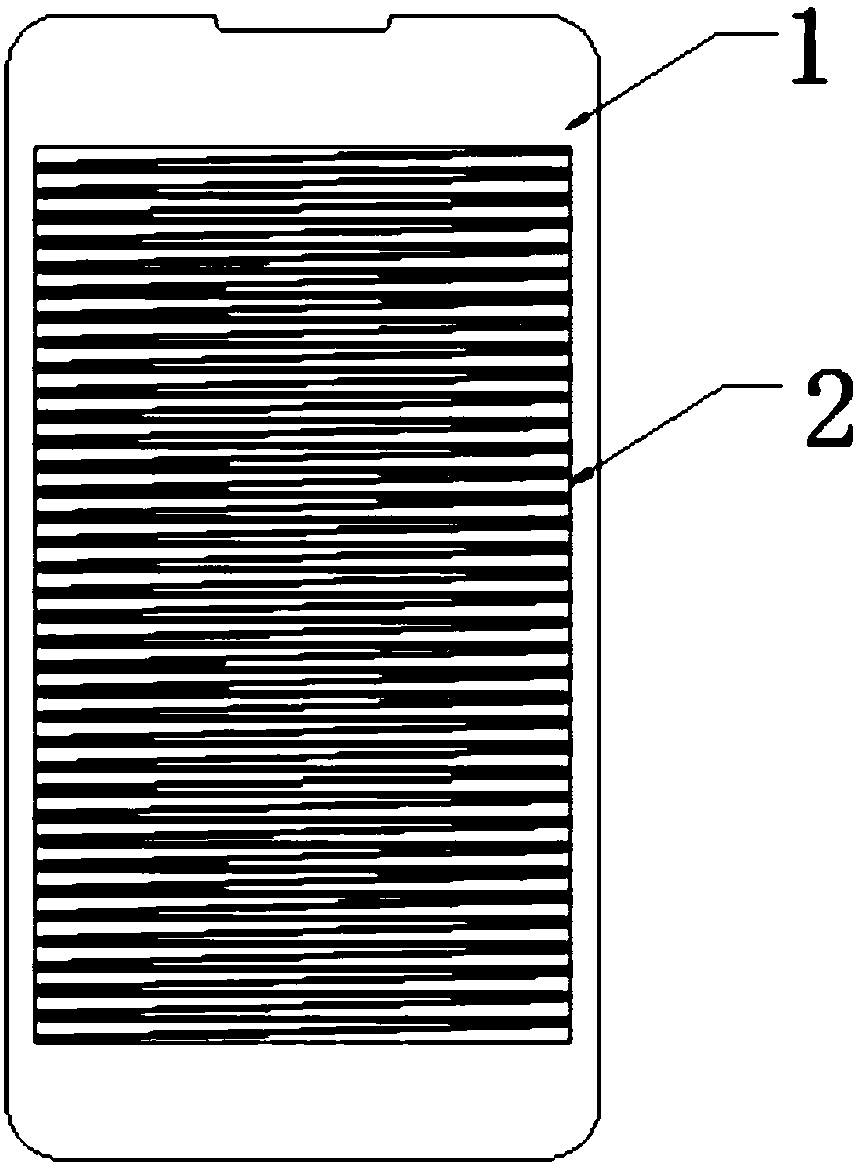

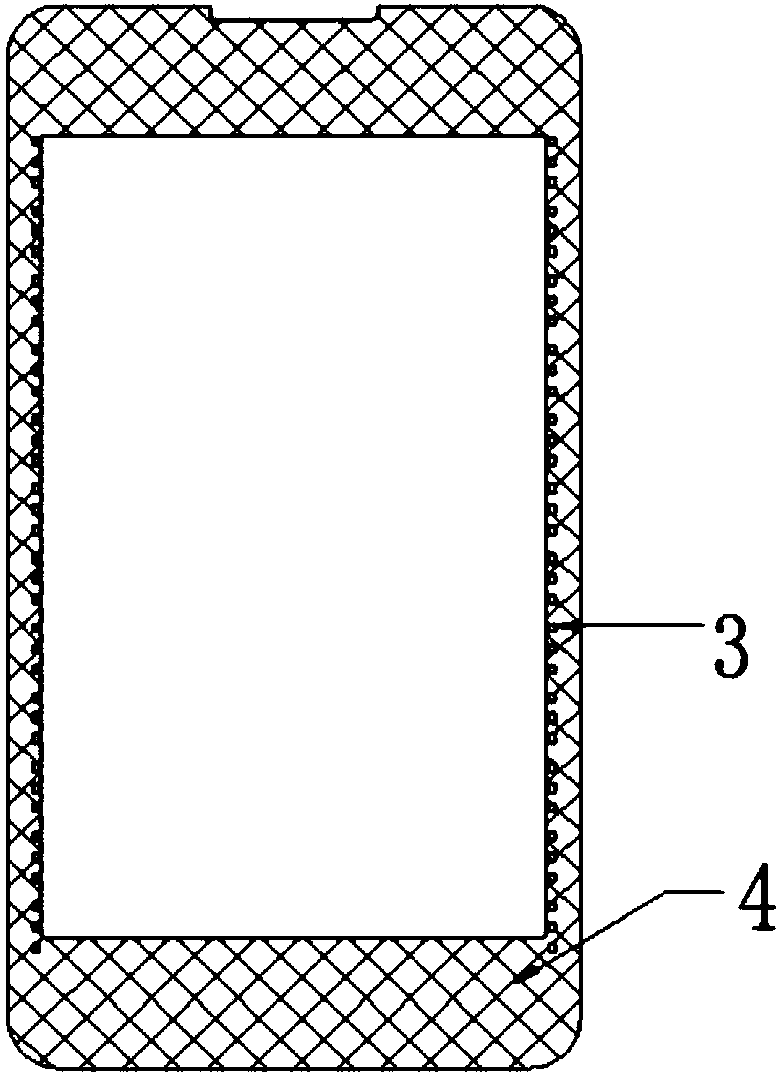

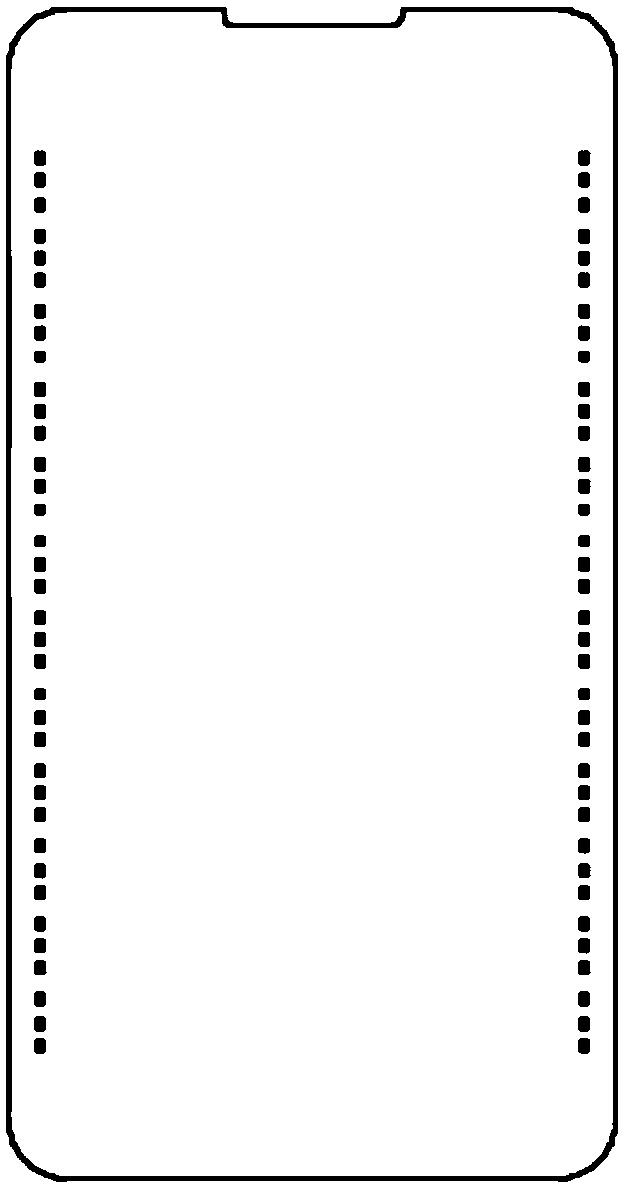

[0036] Such as Figure 1 to Figure 6 Shown, in the present invention, select the glass substrate 1 that has plated ITO for selection, process the ITO electrode 2 earlier by etching process in the first process, as figure 1 shown. Then print the frame layer 4 again. Set up a visible area in the middle of the frame layer 4, and evenly arrange through holes 3 around the visible area, because the metal traces of the ITO electrode 2 and the circuit layer 5 are respectively located on both sides of the frame layer 4, which cannot be solved by general design. There is a conduction problem between these two layers, so through holes 3 are set on the frame layer 4, such as figure 2 shown. The wiring material of the capacitive screen on the circuit layer 5 is generally made of silver paste, which is off-white in color and cannot be directly printed on the through hole 3 of the frame layer 4 . In order to solve this problem, a conductive layer 6 is printed on the through hole 3. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com