Pile testing system for bridge single pile anchoring method based on shoulder pole principle

A technology based on anchor piles and principles, which can be used in foundation structure tests, foundation structure engineering, construction, etc., can solve problems such as difficulty in guaranteeing construction quality, long construction period, and large site occupation, so as to reduce occupancy requirements and hoisting equipment investment requirements, improving installation efficiency and anchoring quality, and saving the construction period of test piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0034] Bridge single pile anchor pile 2 method test pile 1 system based on the principle of shoulder pole:

[0035] 1) Collect the engineering design drawings of test pile 1, master the structure of test pile 1, anchor pile 2 and the corresponding reinforcement layout.

[0036] 2) Design the test pile 1 scheme, and construct the test pile foundation and cap on the foundation to be tested accordingly.

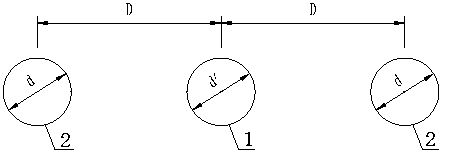

[0037] 3) According to the actual situation of the site, stake out and construct two anchor piles 2 of equal diameter and height at the same distance from both ends of the test pile foundation in a diameter direction (according to the pile diameter of test pile 1, the distance should meet the requirements of the specification), The stakeout accuracy is not less than 1cm. Such as figure 1 As shown, it is the plane layout structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com