Method and system for monitoring equipment life and health based on original fault data

A technology of original failure and equipment life, which is applied in the direction of instrumentation and informatics, and can solve problems such as large randomness, poor applicability of method models, and high difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

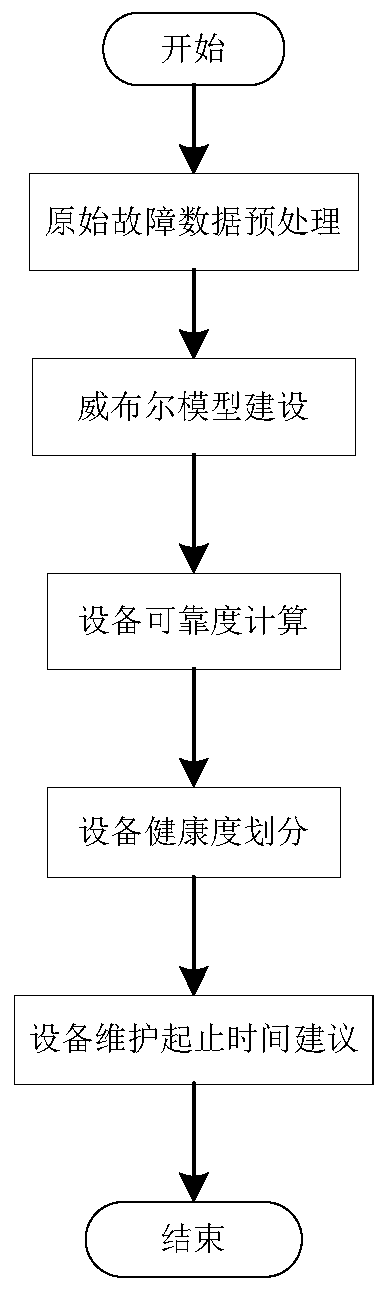

[0105] The device life prediction and health degree monitoring method based on the original fault data of the present invention, such as figure 1 shown, including the following steps:

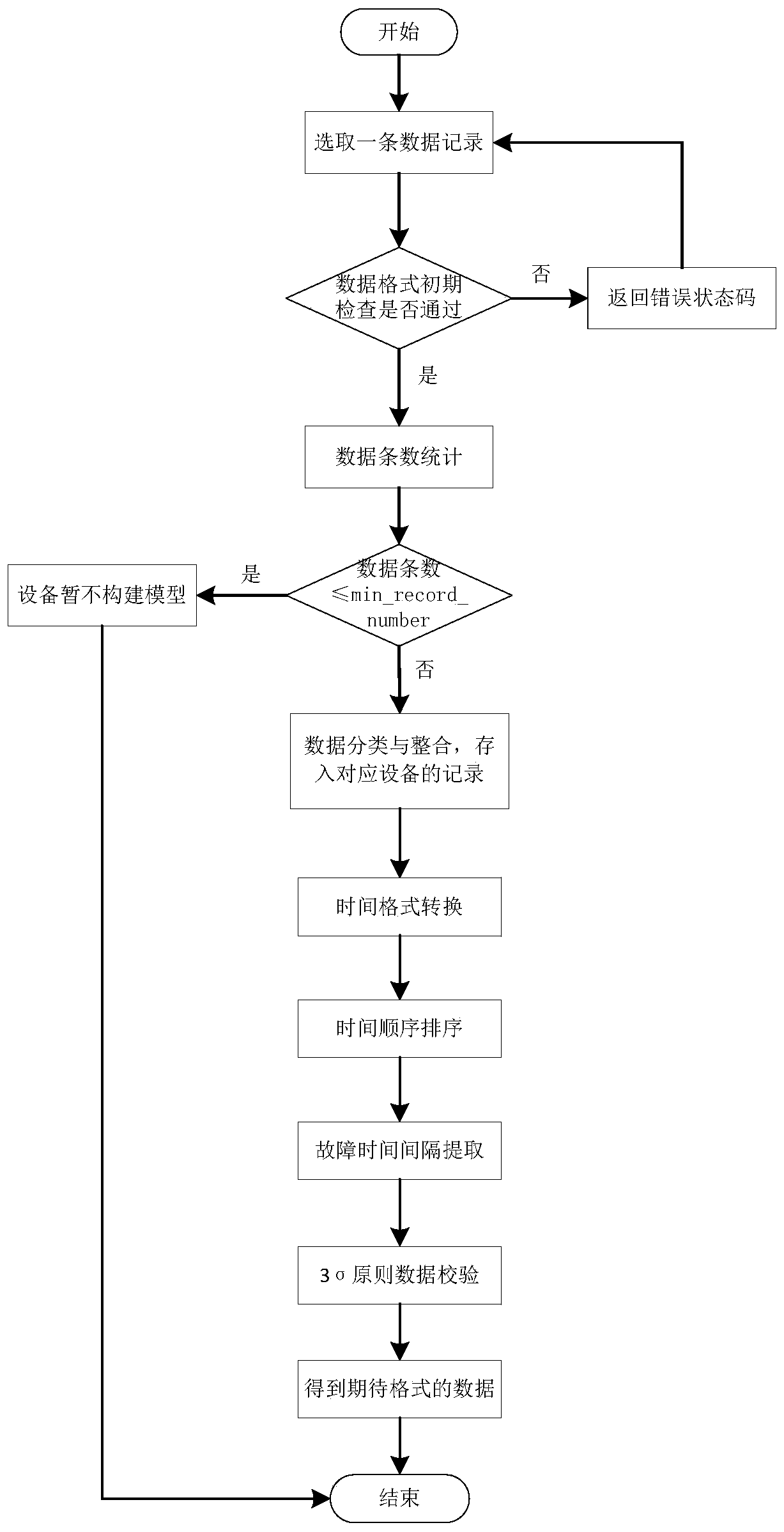

[0106] 1. Raw fault data preprocessing, such as figure 2 As shown, the specific processing steps are:

[0107] 1-1 Initial inspection of data format. Check the format, logic and completeness of historical equipment failure data, equipment maintenance records and equipment inspection records to ensure the correctness of the data input format. If the input is wrong, return the input error status code.

[0108]1-2 equipment modeling discrimination. According to the rated service life and actual usage of the equipment, select the equipment historical failure records, equipment maintenance records, and equipment inspection records within the last 5 years or 10 years, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com