Circuit breaker and assembly method thereof

An assembly method and technology of circuit breakers, which are applied in the manufacture of circuits, emergency protection devices, emergency protection devices, etc., can solve the problems of many artificial assembly problems, difficult assembly, and many parts of circuit breakers, and achieve the difficulty of installation operation and low accuracy requirements , Improve stability and accuracy consistency, compact and stable assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

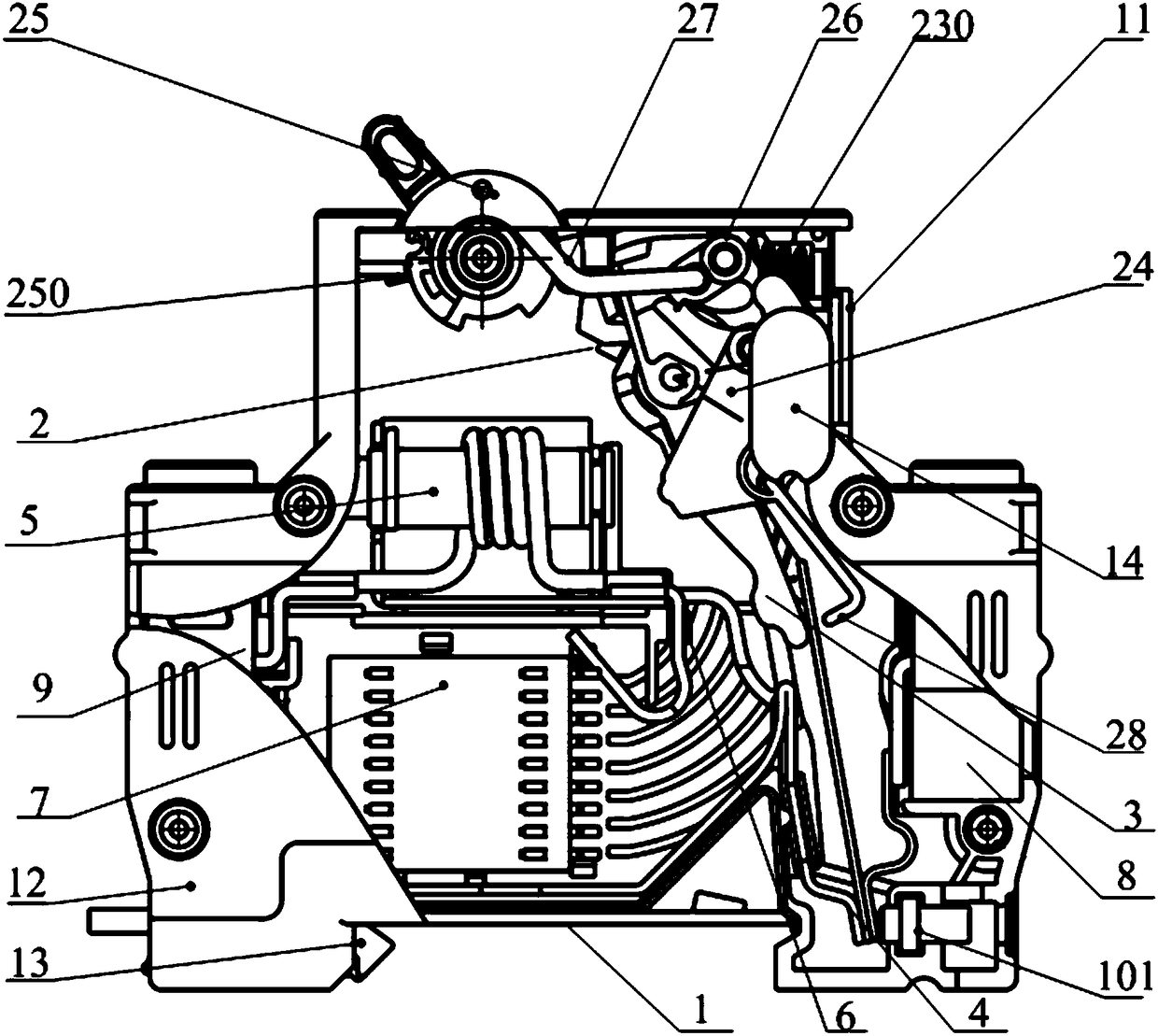

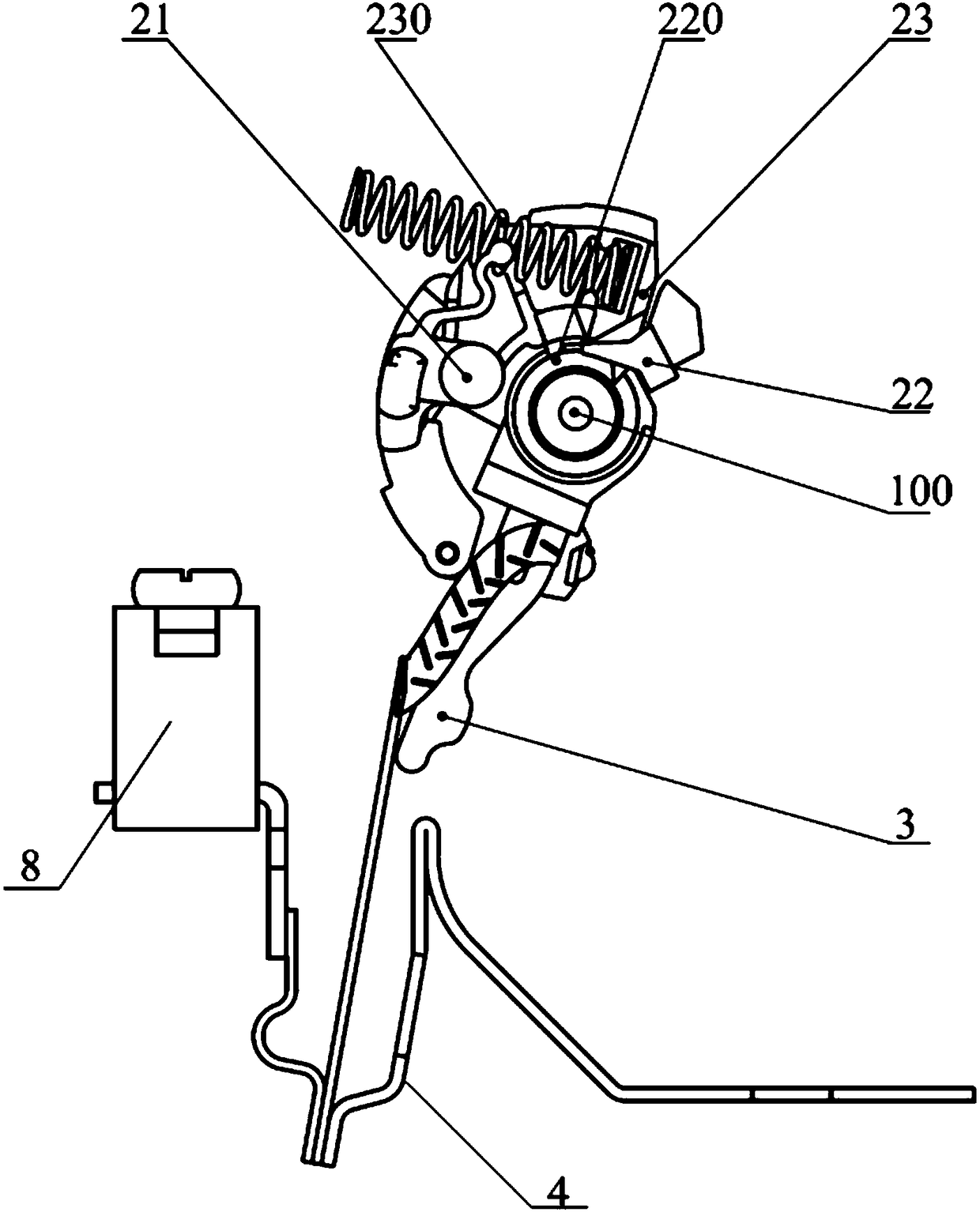

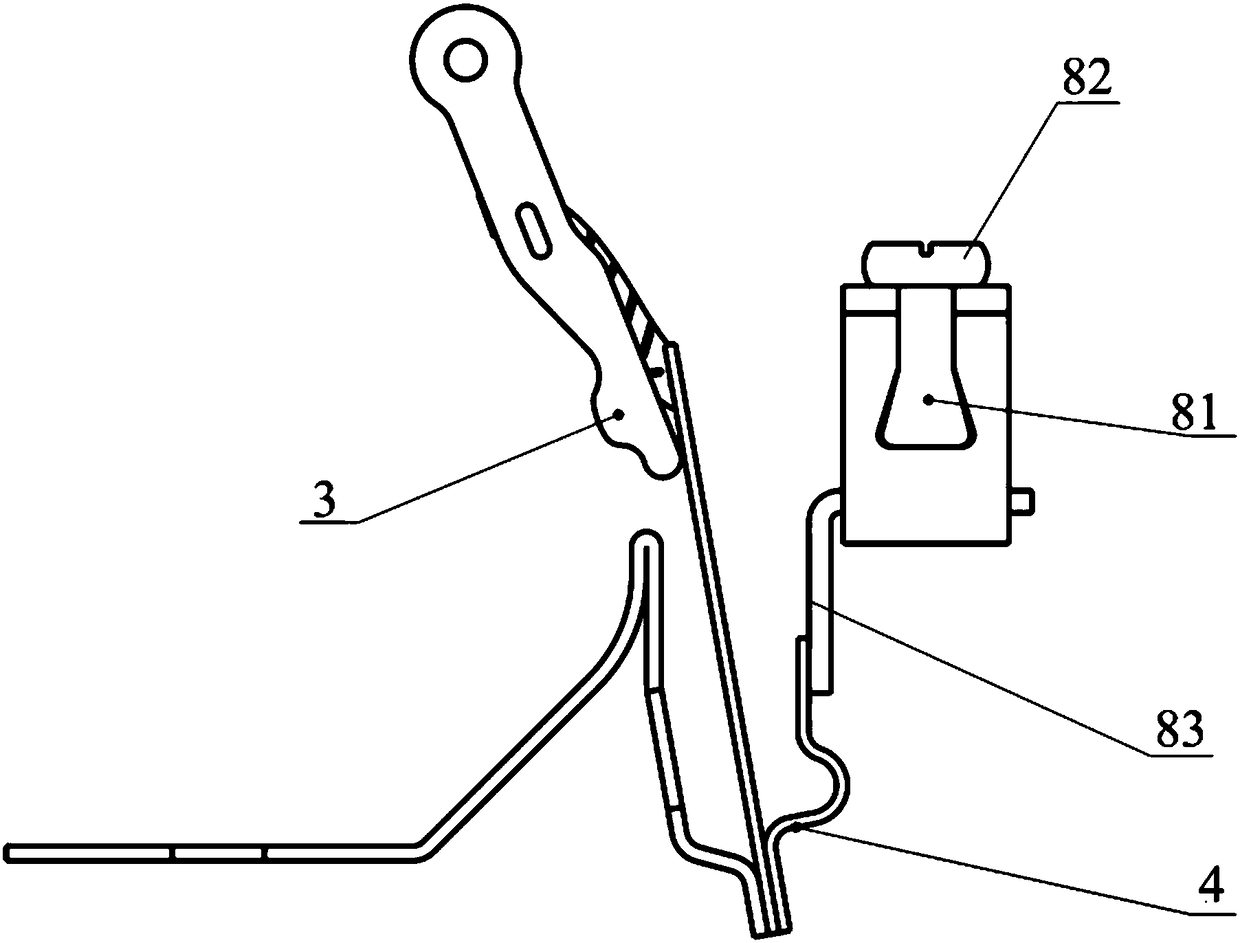

[0037] The following is attached Figures 1 to 10 The given examples further illustrate the specific implementation of the circuit breaker and its assembly method of the present invention. The circuit breaker and its assembly method of the present invention are not limited to the description of the following embodiments.

[0038] Such as figure 1 and figure 2 As shown, the circuit breaker of the present invention includes a housing 1, an operating mechanism 2 installed in the housing 1, a moving contact 3, a thermal system 4, a magnetic system 5, a static contact 6, an arc extinguishing chamber 7, a second A connection terminal 8 and a second connection terminal 9, the housing 1 includes a base 11, an upper cover 12, a stopper 13 and a cover plug 14, the upper cover 12 can be fastened and installed on the base 11; the operating mechanism 2 It includes a handle 25 , a U-shaped rod 27 , a connecting rod 26 , a limiting piece 21 , a lever 23 , a contact support 22 , a lock ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com