Winding device with base for vertical pouring

A winding and base technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor components, coil manufacturing, etc., to avoid crack formation and simplify preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

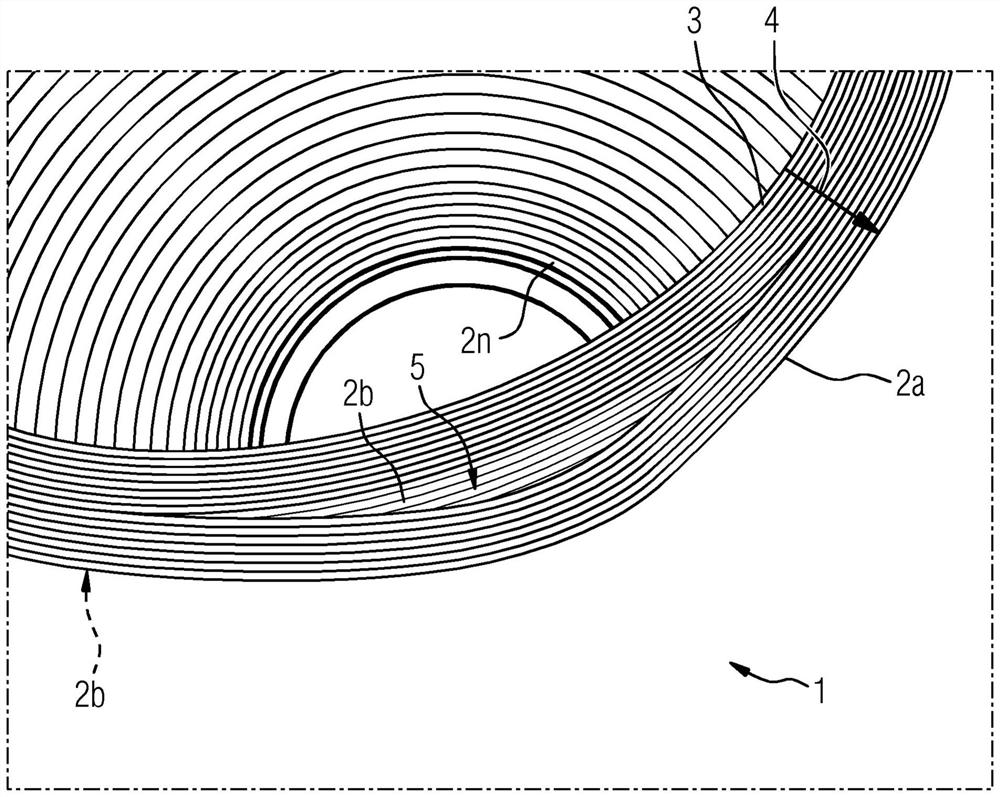

[0034] figure 1An exemplary embodiment of the winding arrangement 1 according to the invention is shown in a perspective view from below. It can be seen that the winding arrangement 1 has a plurality of disk windings 2 , 2 b , 2 c . It can be seen that the disk winding 2a and also all the other disk windings 2b...2n are assembled from a plurality of winding layers 3 with strip-shaped, ie flat, conductors which are rolled from the inside to the outside. Winding, wherein each disc winding 2a, 2b, 2c, . . . 2n increases in radial direction 4. Here, the strip-shaped conductors are insulated from one another. The insulation part is in figure 1 The illustrated embodiment is provided by a layer of paint that has been applied to the conductor. Depend on figure 1 It can be seen in particular that the disc winding 2 a forms a recess 5 which is provided for receiving a fixed end of the base element.

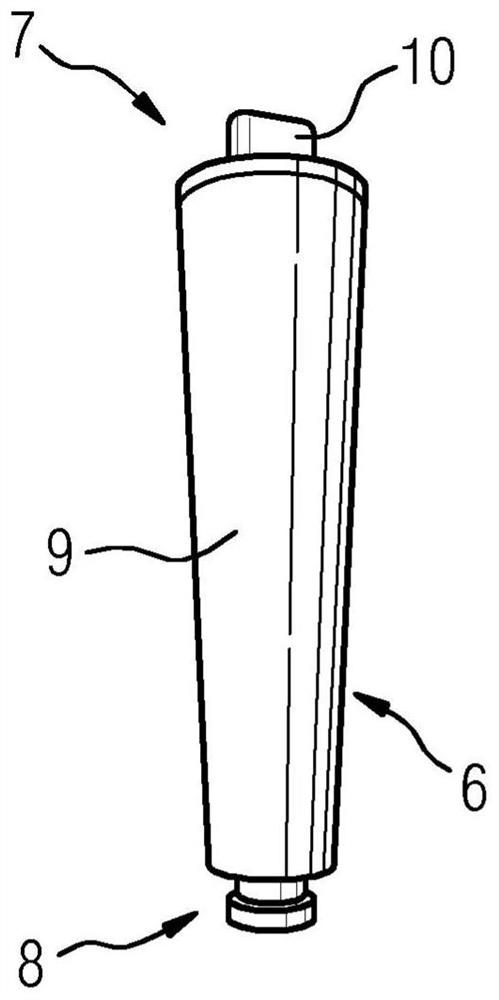

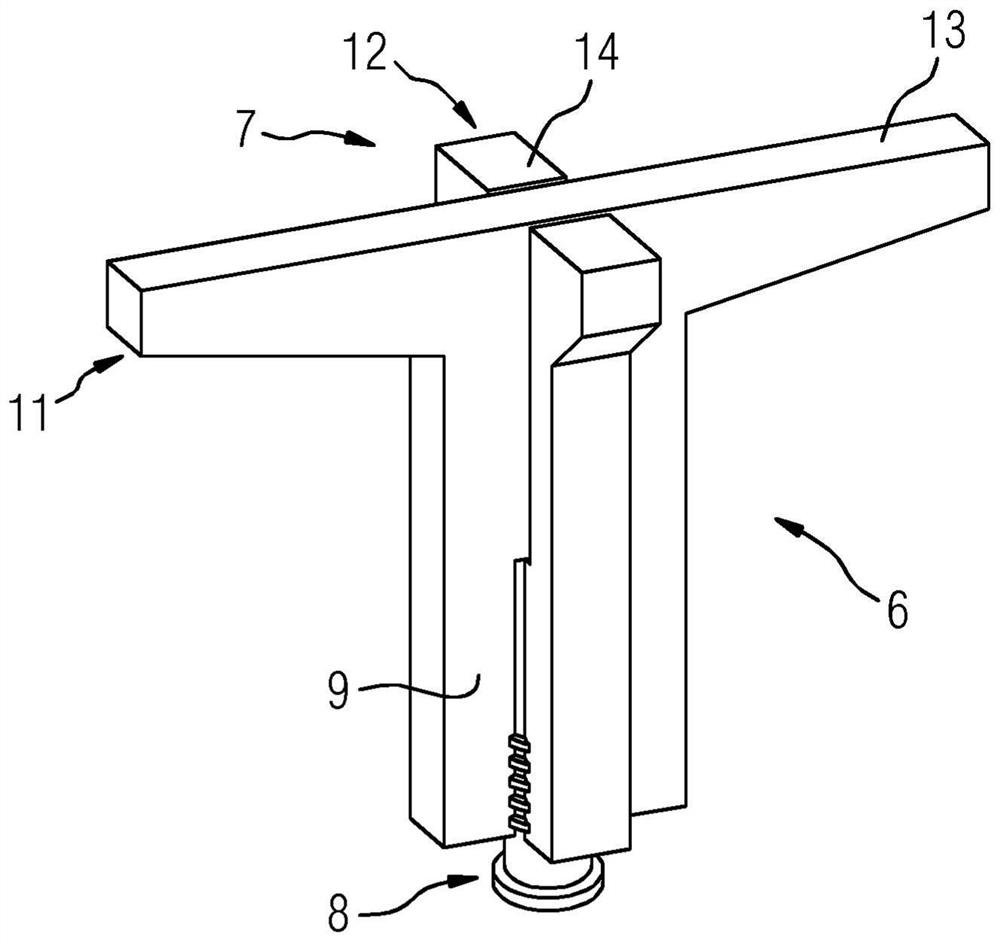

[0035] figure 2 An embodiment of a base element 6 is shown, which has a fixed e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com