Mechanical arm mechanism with explosion protection

A robotic arm and structure technology, applied in manipulators, claw arms, manufacturing tools, etc., can solve problems such as increased flexibility, decreased precision, and structural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

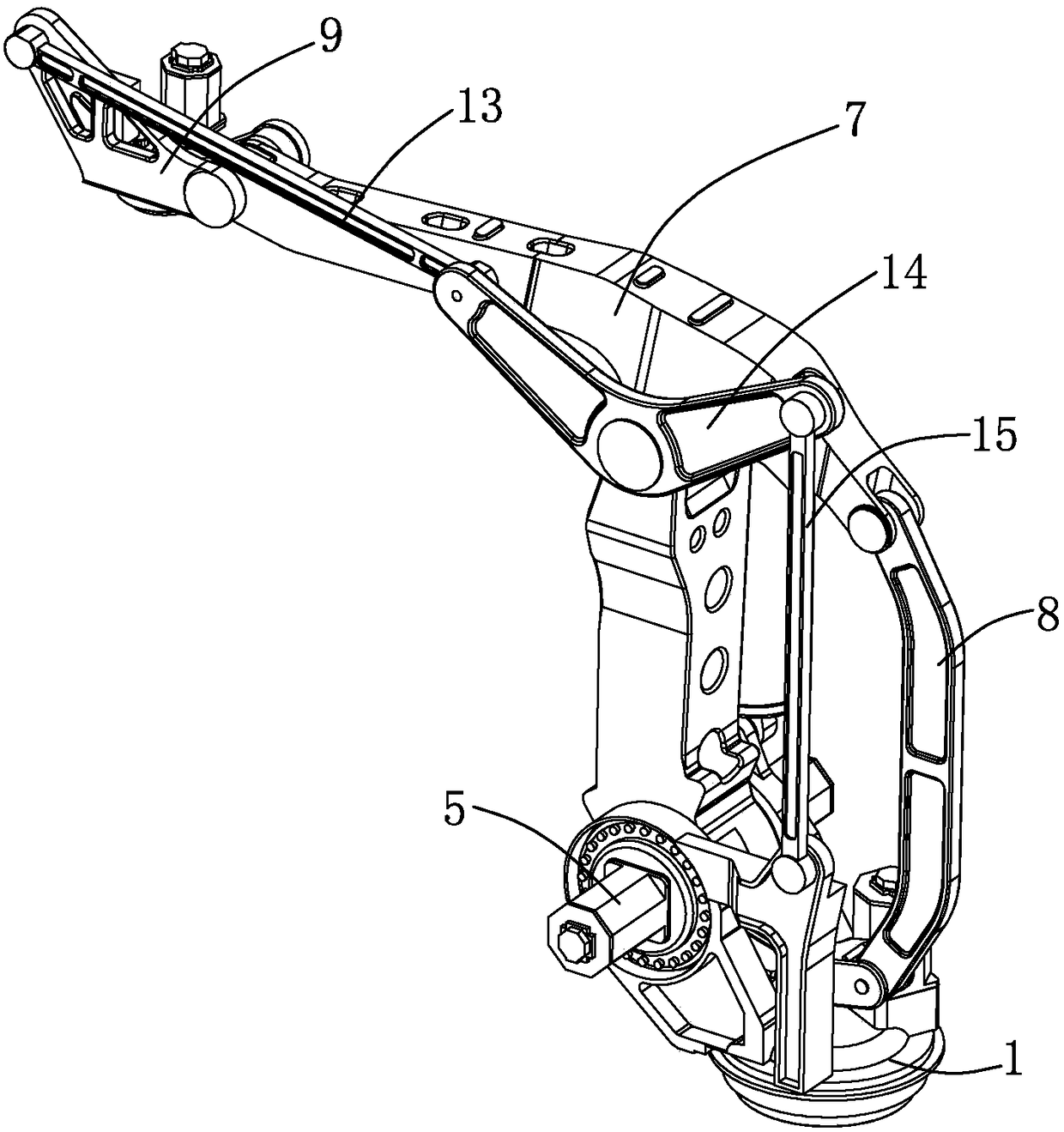

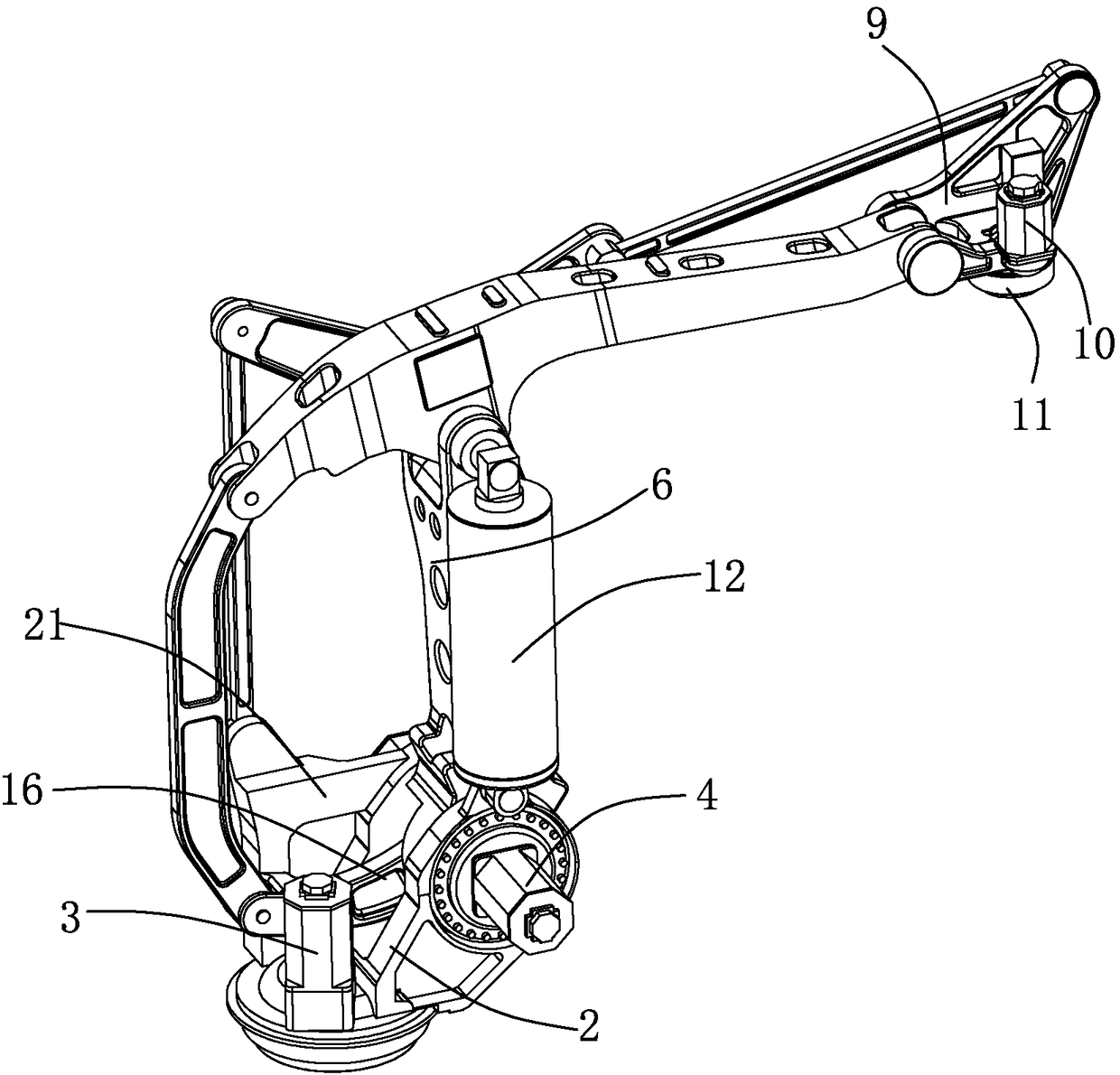

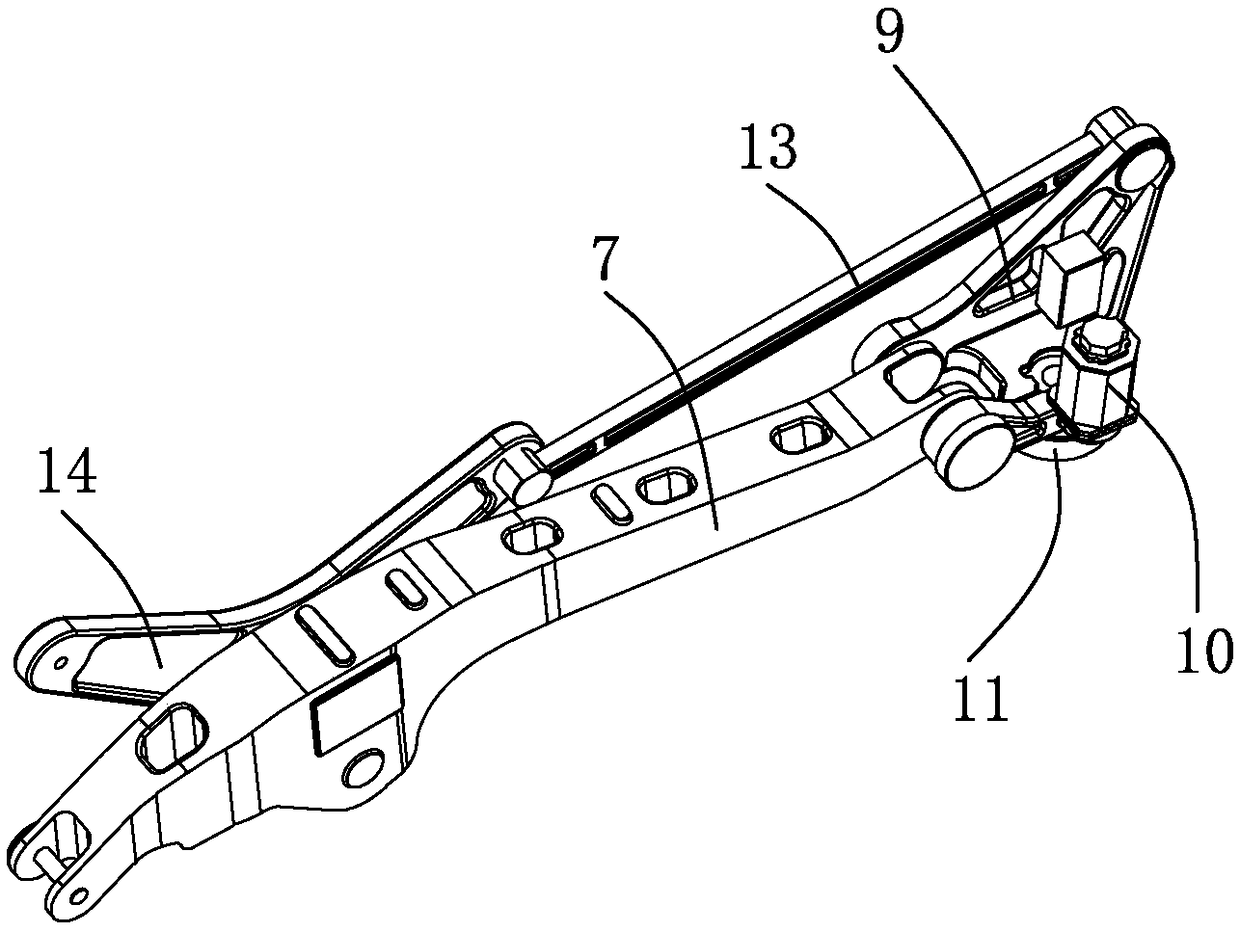

[0025] Embodiment: An explosion-proof mechanical arm mechanism, its main structure includes: rotating chassis 1, base bracket 2, bracket frame 21, inner concave cavity 22, reduction motor a3, left reduction motor 4, right reduction motor 5, lift Arm 6, suspension rod 7, pull rod arm 8, triangular workpiece 9, electric telescopic device 10, electromagnetic chuck 11, foaming agent tank 12, pull rod a13, V-shaped workpiece 14, pull rod b15, pull arm 16, described rotation A base bracket 2 is welded and fixed on the chassis 1, and the rotation of the base bracket 2 is driven by a reduction motor a3 fixed thereon, and the rotation range of the base bracket 2 is 0-340 degrees;

[0026] One end of the base support 2 is provided with a support frame 21, and the middle position of the base support 2 is provided with an inner concave cavity 22; the left and right reduction motors 4 and 5 of the base support 2 are respectively fixed on the left and right sides of the base support; The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com