Tire forming drum with improved structure

A technology of tire building drum and drum plate, applied in the field of tire building drum, can solve the problems of shortened service life of main shaft, large main shaft load, heavy drum plate weight, etc., so as to prolong service life, reduce weight, reduce manufacturing cost and maintenance cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

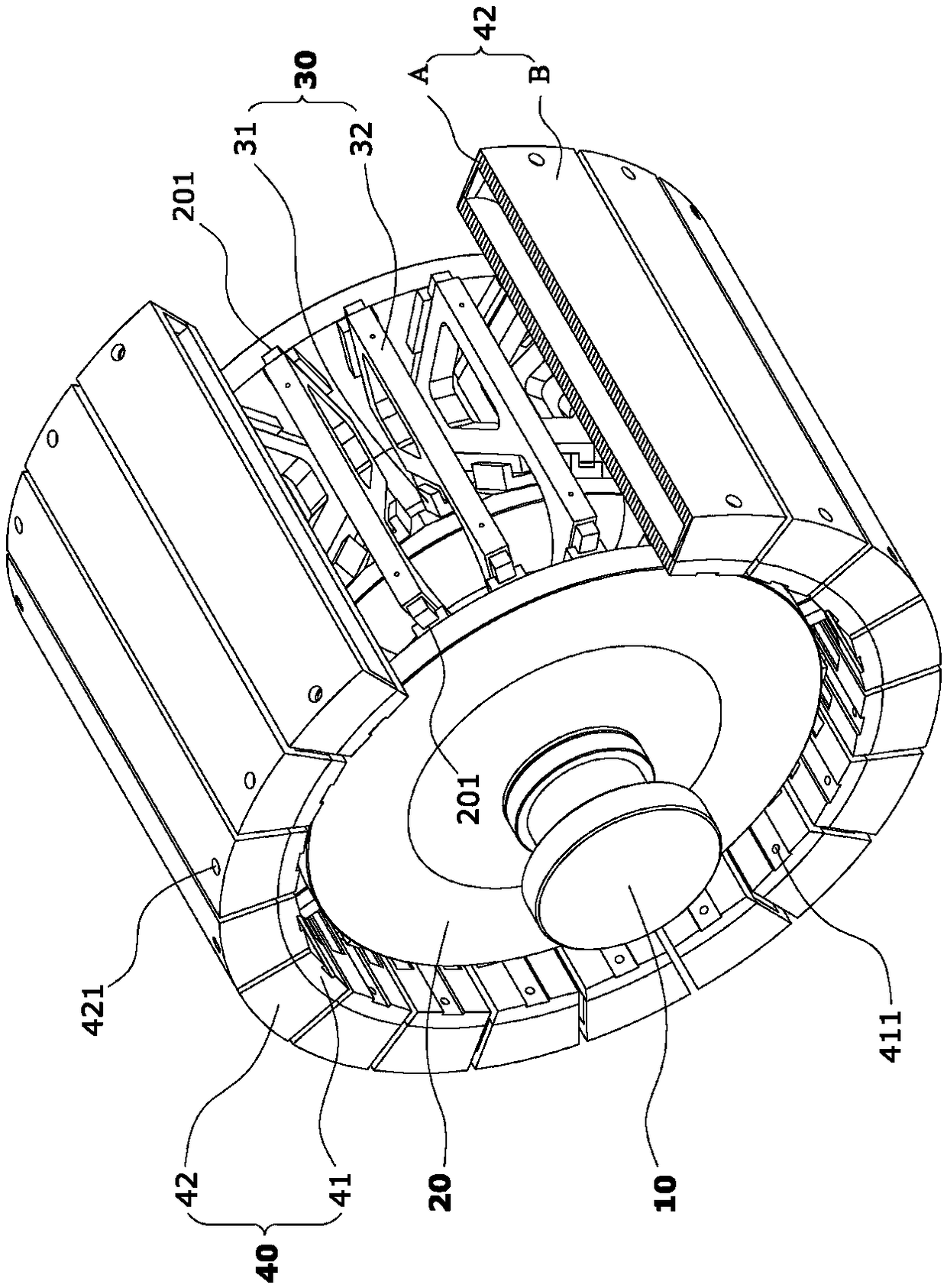

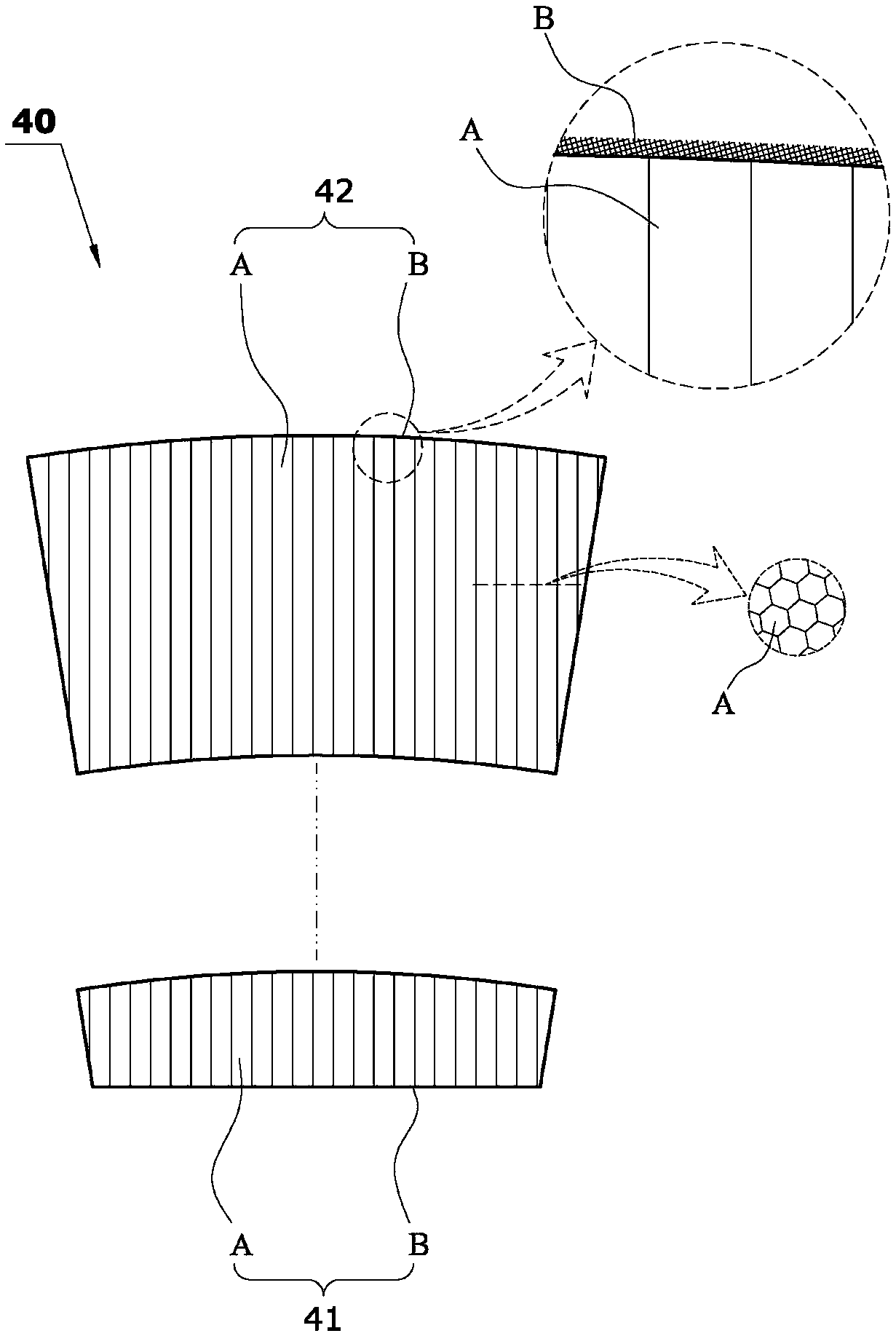

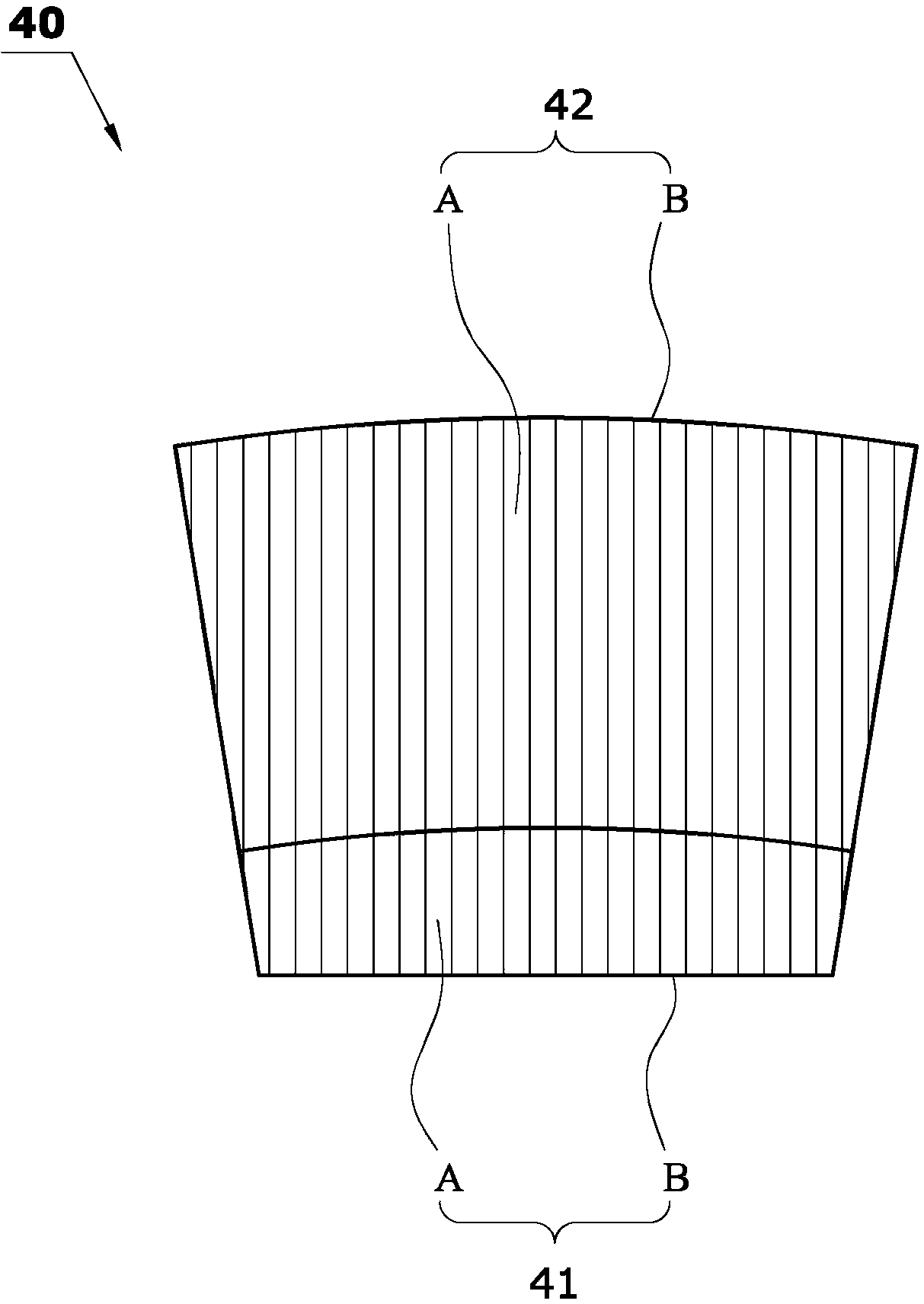

[0015] Such as figure 1 The tire building drum of a kind of structural improvement shown, comprises a main shaft 10, is installed in the side plate 20 of annular ring 10 both sides of main shaft 10, is provided with some arc-shaped drum plates 40 around the circumferential direction of side plate 20, two On the main shaft 10 between the side plates 20, several groups of telescopic devices 30 for driving the drum board 40 to move back and forth in the radial direction are installed, and one group of telescopic devices 30 drives a drum board 40; each group of telescopic devices 30 includes a lower support 31 And an upper supporting part 32, the top of the upper supporting part 32 is connected and fixed with the drum plate 40; Guide rail 201 is slidably connected, and upper support member 32 is connected with the inclined guide rail of lower support membe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com