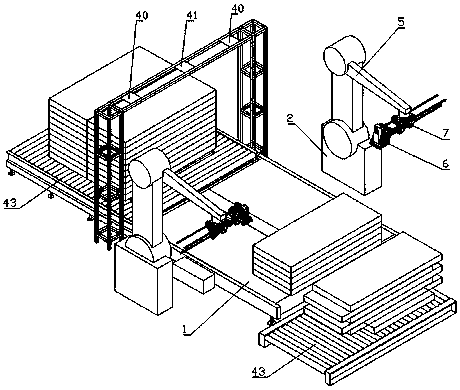

Corrugated board turning and staggered-stacking system

A technology of corrugated cardboard and flipper, which is applied in the direction of turning over objects, stacking receiving devices, pile separation, etc. It can solve the problems of affecting printing and forming, manual turning over is laborious, and low efficiency, so as to save labor and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

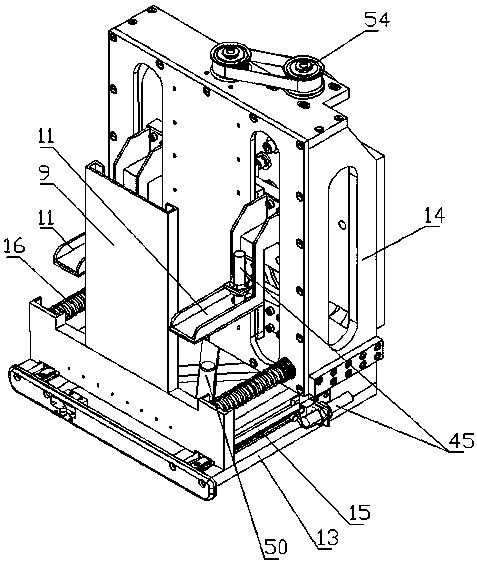

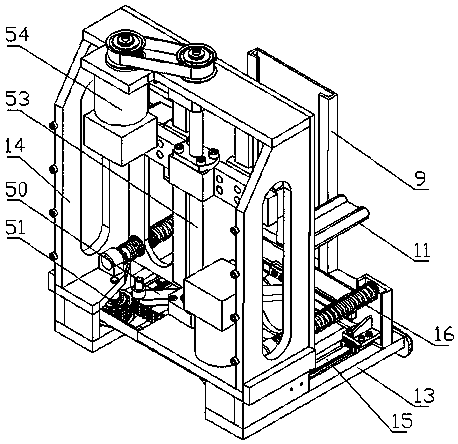

[0013] As shown in the drawings, the present invention includes a mesh belt conveyor 1 and a pair of flipping and stacking robots 2. A pair of flipping and stacking robots 2 are respectively located on both sides of the mesh belt conveyor 1. Person 2 includes a two-axis manipulator 5, a grabbing device 6 and a grabbing device control arm 7, and the grabbing device 6 includes a bottom support plate 13, a gripper frame 14, a baffle 9, a baffle telescopic assembly, a pair of pressing plates 11 and a pressing plate Lifting assembly, the handle frame 14 is installed on the bottom support plate 13, a pair of guide rails 15 are arranged on the bottom support plate 13, the baffle plate 9 is installed on the sliders of the pair of guide rails 15, and the baffle telescopic assembly is installed on the handle frame 14 and drive the baffle plate 9 to slide on a pair of guide rails 15, the two ends of the baffle plate 9 are respectively provided with guide rods 16, and a pair of guide rods ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap