Forklift

A technology for forklifts and frames, applied in the field of lifting equipment, can solve the problems of different weights, low work efficiency, and high costs, and achieve the effects of ensuring normal use, low manufacturing costs, and wide application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

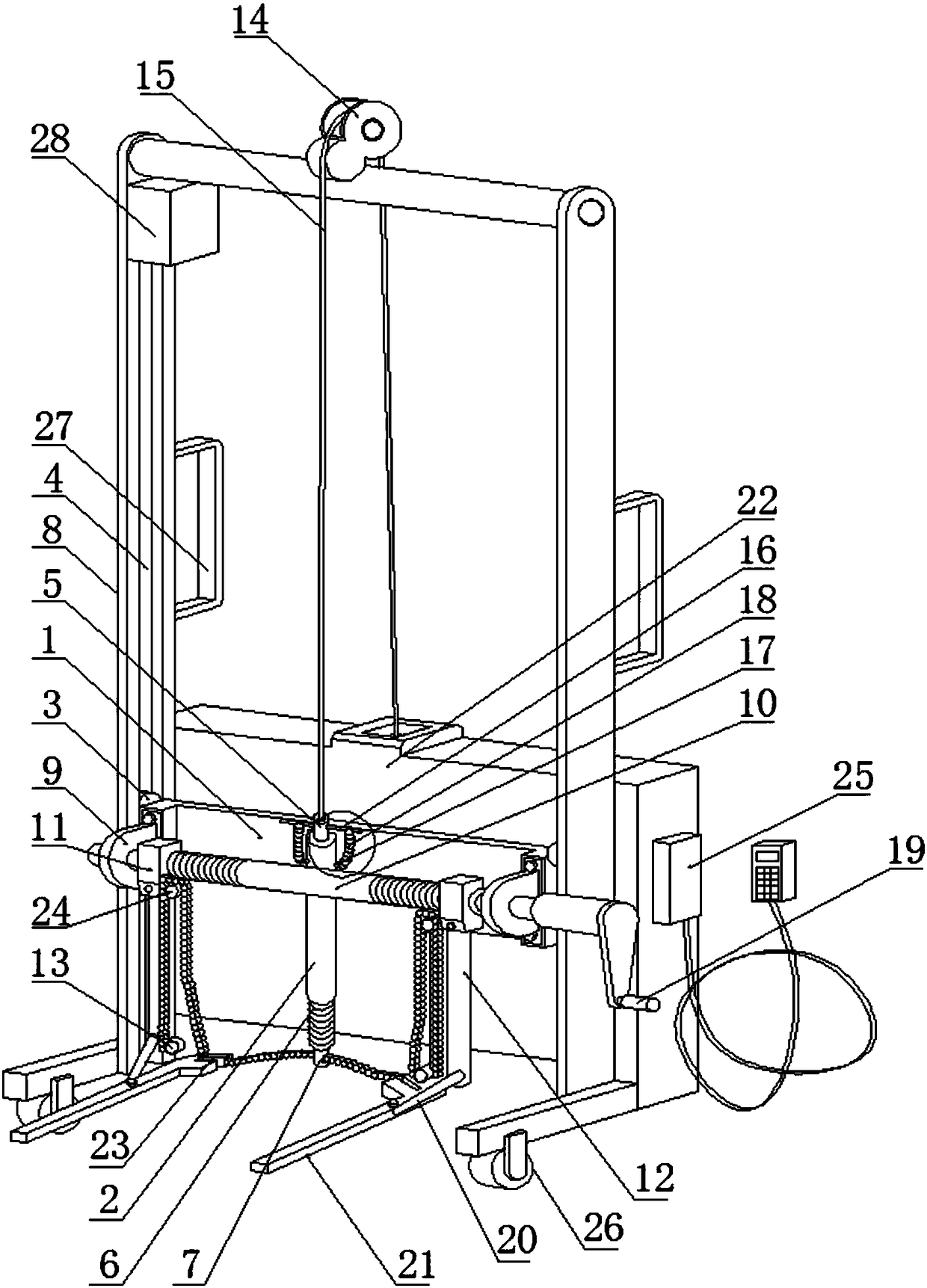

[0022] Embodiment 1, with reference to figure 1 —2, a kind of forklift, comprises warehouse body, and described forklift comprises vehicle frame 8;

[0023] The vehicle frame 8 is provided with a lifting mechanism, and the lifting mechanism includes a lifting plate 1, a lifting bushing 2 fixed on the lifting plate 1 and a lifting shaft 5 arranged in the lifting bushing 2; Both sides of the board 1 are provided with slide blocks 3, and the frame 8 on both sides of the lifting board 1 is provided with slide rails 4 used in conjunction with the aforementioned slide blocks 3; the bottom end of the lifting shaft sleeve 2 and the bottom end of the lifting shaft 5 are An elastic element 6 is connected between them, and a through hole 7 is also provided at the bottom end of the lifting shaft 5;

[0024] The vehicle frame 8 is also provided with a clamping mechanism, and the clamping mechanism includes two supports 9 fixed on the lifting plate 1, a rotating shaft 10 pierced on the two...

Embodiment 2

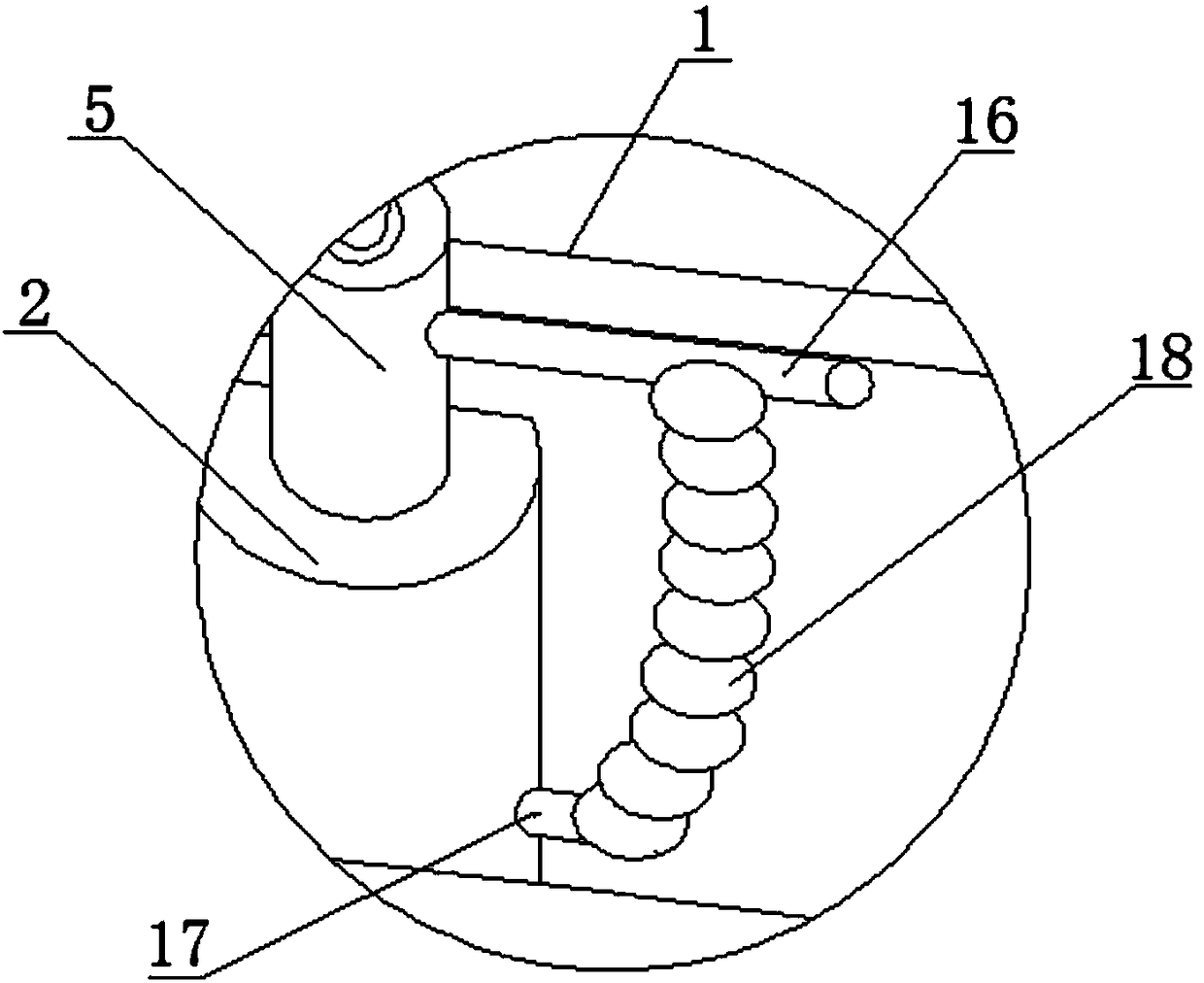

[0026] Embodiment 2, a kind of forklift described in embodiment 1, described lifting mechanism is also provided with auxiliary lifting mechanism, and described auxiliary lifting mechanism comprises the connecting shaft 16 that crosses on aforementioned lifting shaft 5, is arranged on The extension spring mounts 17 on both sides of the lifting bushing 2 and the extension spring 18 connected between the connecting shaft 16 and the extension spring mounts 17 .

Embodiment 3

[0027] Embodiment 3, a kind of forklift described in Embodiment 1, the distance adjustment mechanism is also provided on the described clamping mechanism, and the distance adjustment mechanism includes the aforementioned rotating shaft 10, the rotating arm mounting seat 11 and the The handle 19 at the end; the shaft 10 is tapped with thread; the rotating arm mounting seat 11 is provided with a thread used in conjunction with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com