Flexible element, flexible display equipment and manufacturing method thereof

A flexible component and flexible display technology, applied in the direction of electrical components, chemical instruments and methods, electric solid devices, etc., can solve the problems of display panel blocking, difficulty, and poor implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

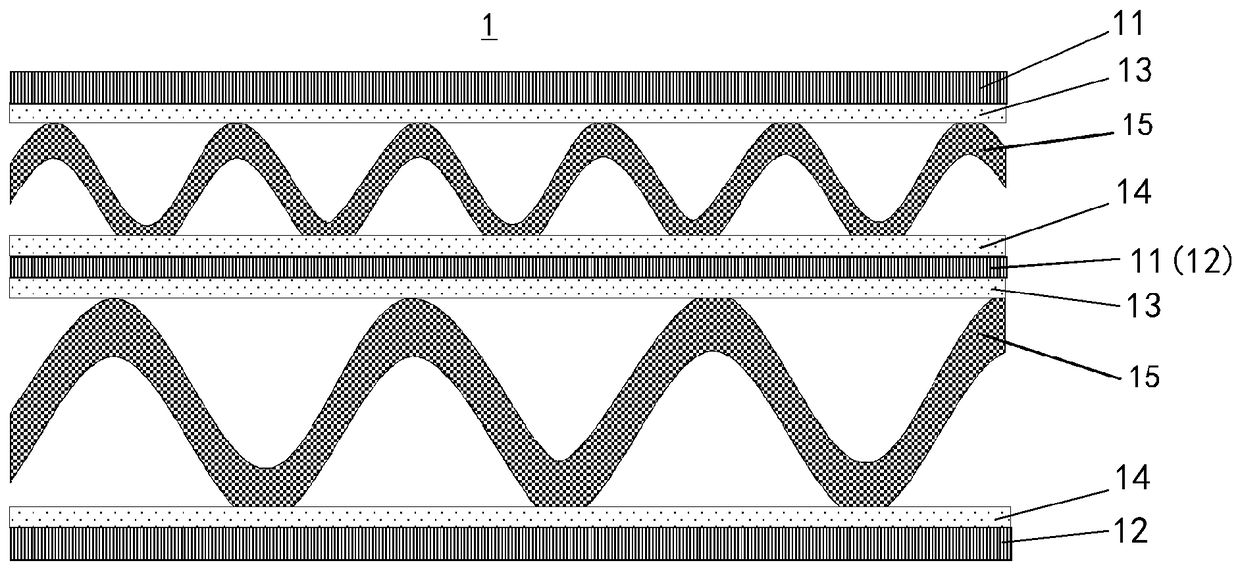

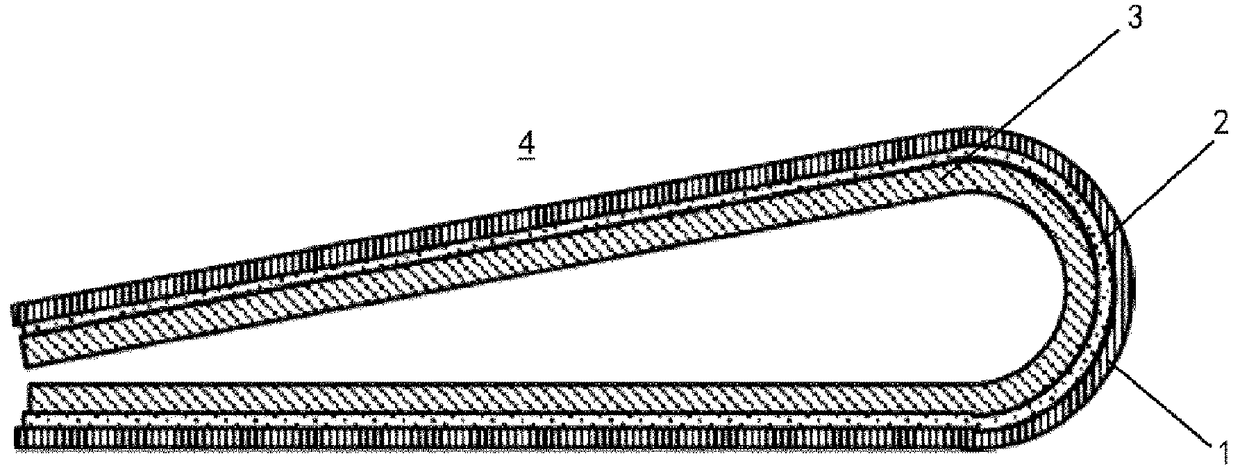

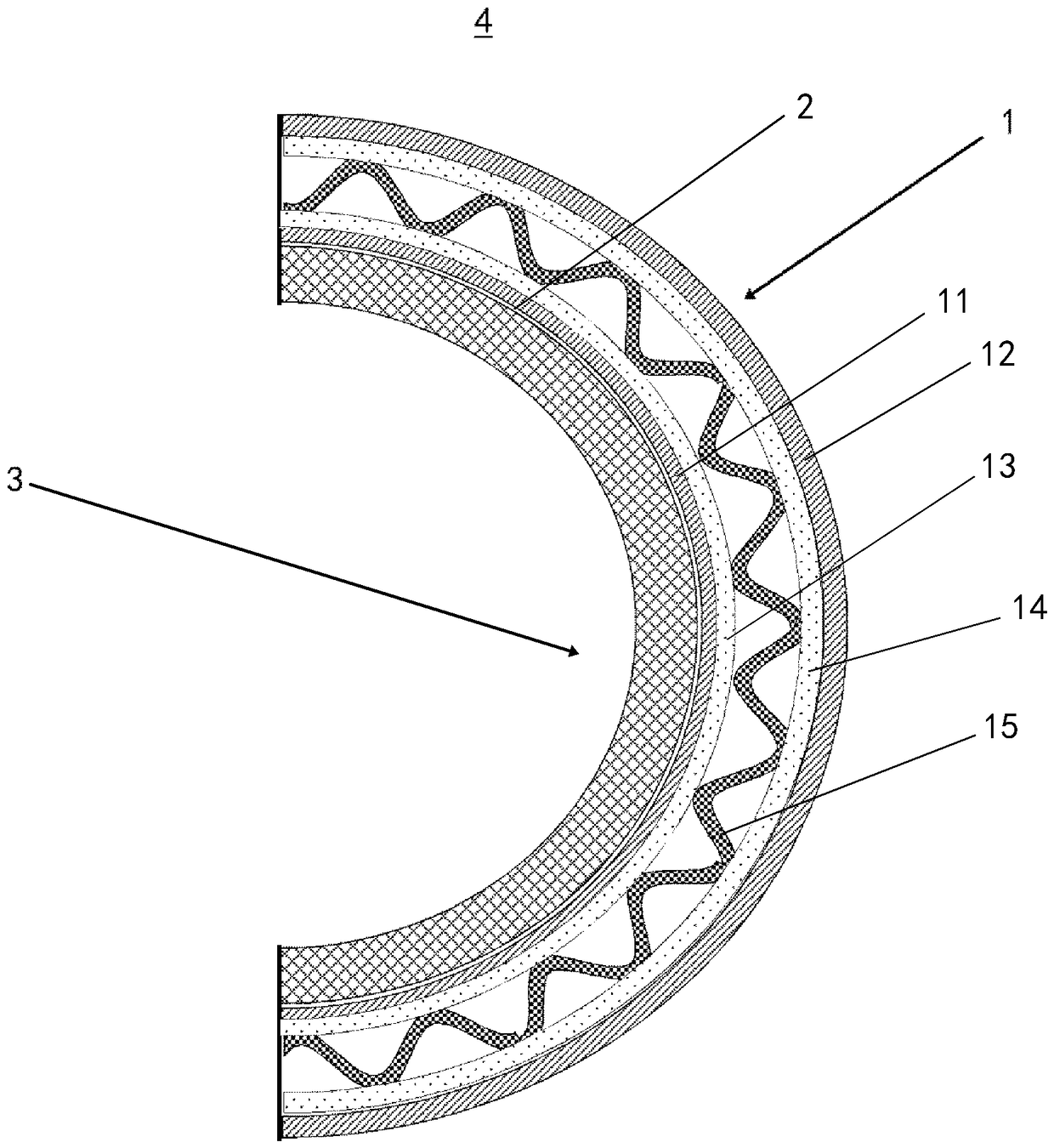

[0037] Please also refer to Figure 1-12 , the present disclosure takes an OLED display panel with top emission (that is, the surface facing away from the flexible element 1 as the emitting surface, that is, the display surface) as an example to elaborate. According to an embodiment of the present disclosure, the flexible display panel 3 The surface of the non-display substrate (i.e. the back side of the flexible display panel 3, i.e. figure 1 The flexible element 1 on the lower surface of the flexible display panel 3) includes: a first base layer 11 and a second base layer 12 oppositely arranged; and a buffer layer 15 sandwiched between the first base layer 11 and the second base layer 12, Wherein, the flexible element 1 can be bent around a bending axis (not shown in the figure), and the projection of the buffer layer 15 on a plane perpendicular to the bending axis is wavy. Since the flexible element 1 has a certain mechanical strength and excellent flexibility, when it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com