Full-automatic pickling tank

A fully automatic, tank-based technology, applied in the direction of food science, etc., can solve the problems of unfavorable large-scale production of pickled products, heavy labor of operators, and inconvenient operation, so as to improve pickling efficiency, high pickling quality, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

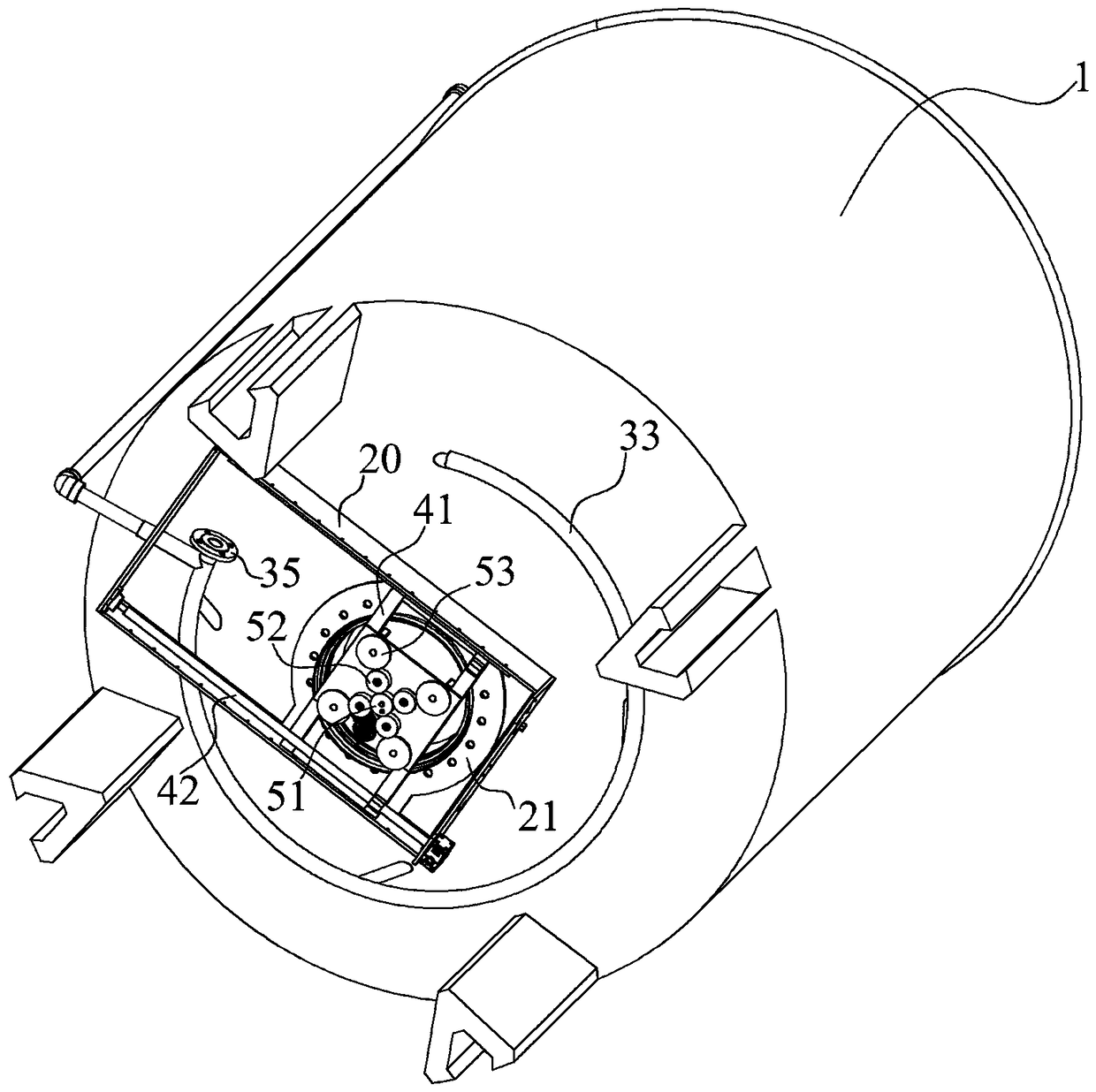

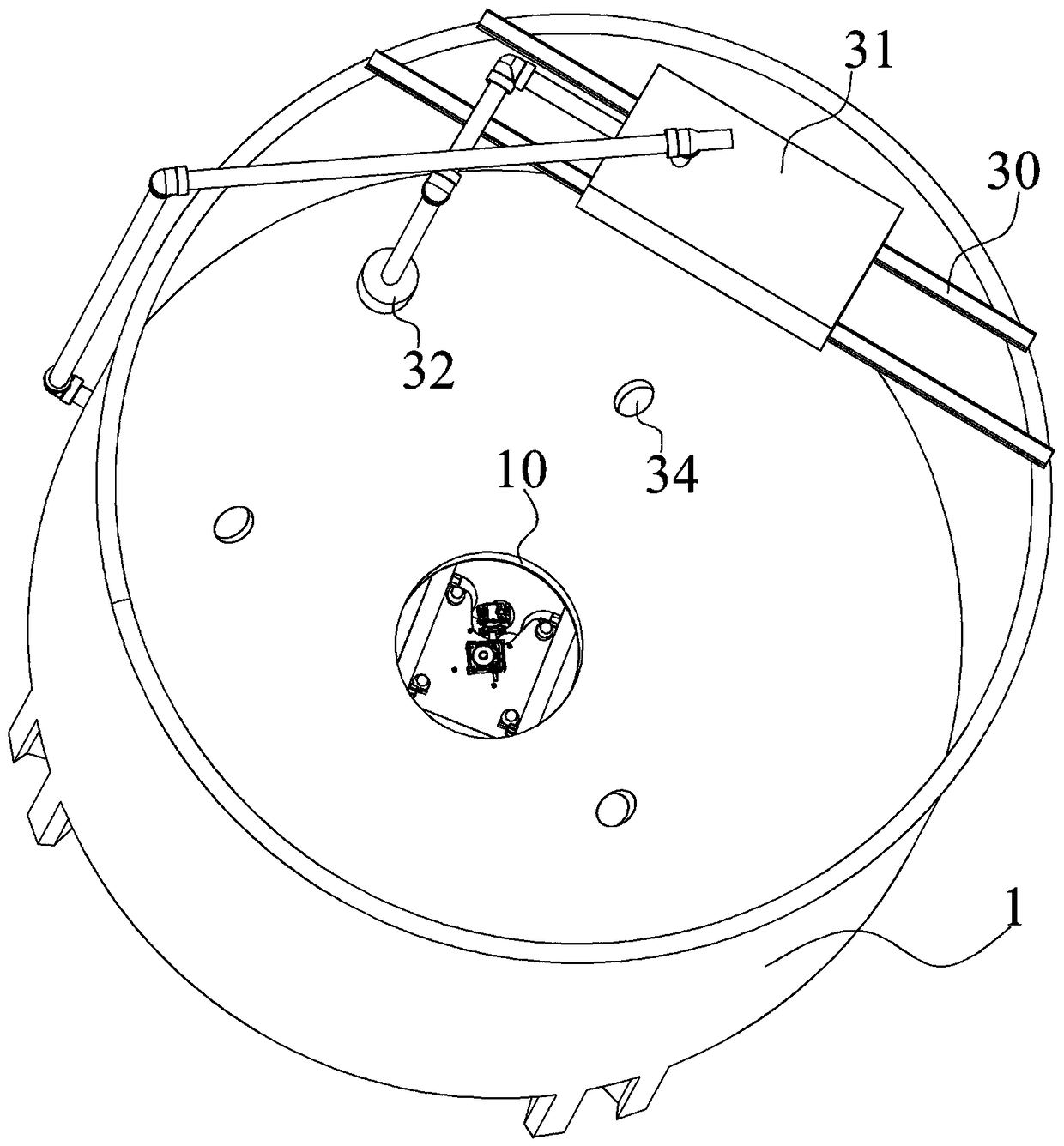

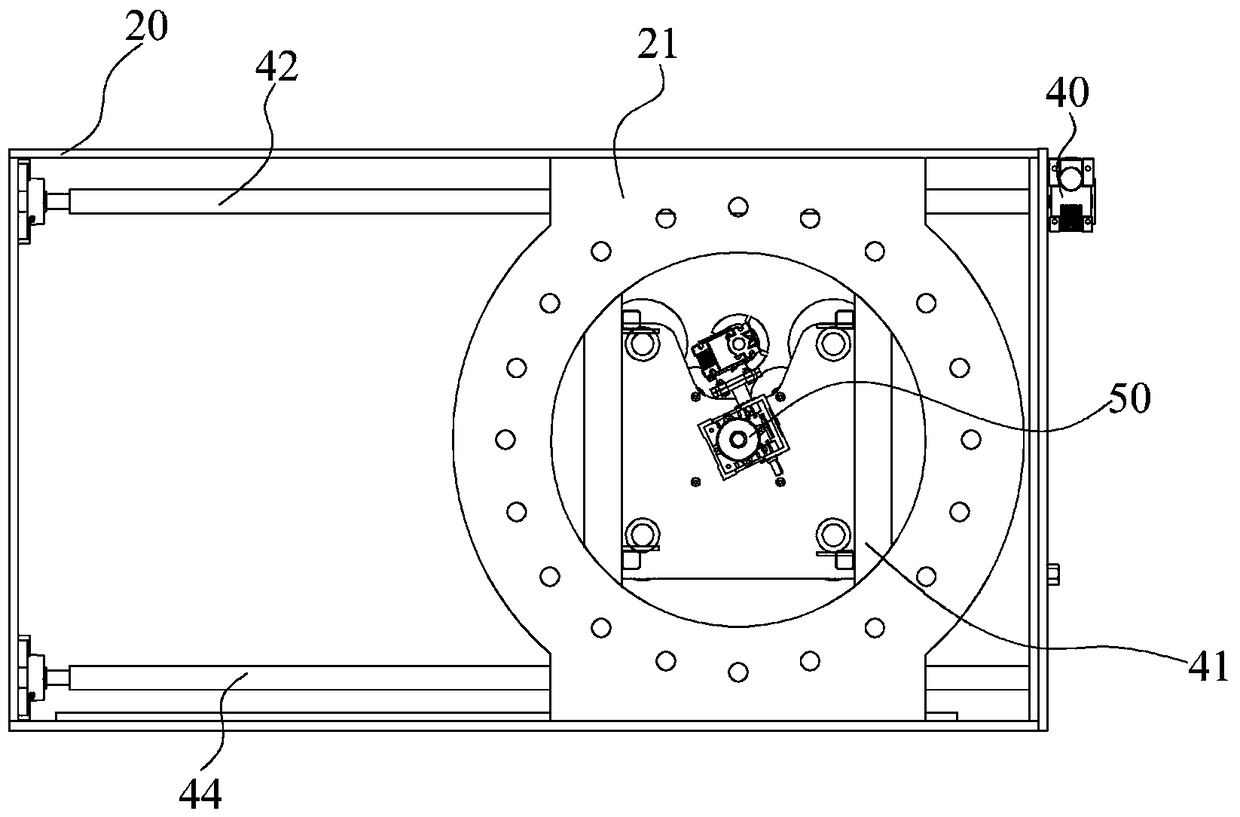

[0018] Embodiment 1: as Figure 1-5 As shown, the present invention designs a fully automatic pickling tank, comprising a tank body 1, a sealing valve 2 arranged under the tank body 1, a circulation mechanism 3 arranged on the top of the tank body 1, and the bottom of the tank body 1 is provided with a useful The sealing valve 2 is fixed below the feeding port 10 through the flange; the circulation mechanism 3 includes a support frame 30 fixed on the upper edge of the tank body 1, and is arranged on the support frame 30. The liquid storage tank 31 on the tank body 1 is suspended with a circulation pump 32 inside the tank body 1, and the circulation pump 32 is connected with the liquid storage tank 31 through a pipeline. The bottom of the tank body 1 and the outer circumference of the feeding port are provided with three circulation ports 34, and the arc circulation pipes 33 communicate with the circulation ports 34 through connecting pipes respectively, and the ends of the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com