Steamed stuffed bun filling outputting device capable of outputting various fillings

A technology for fillings and buns, which is applied to the field of filling devices for buns with multiple fillings, can solve the problems of good taste of buns and filling with a single filling, and achieves the effects of accurate filling amount, convenient switching, and guaranteed practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

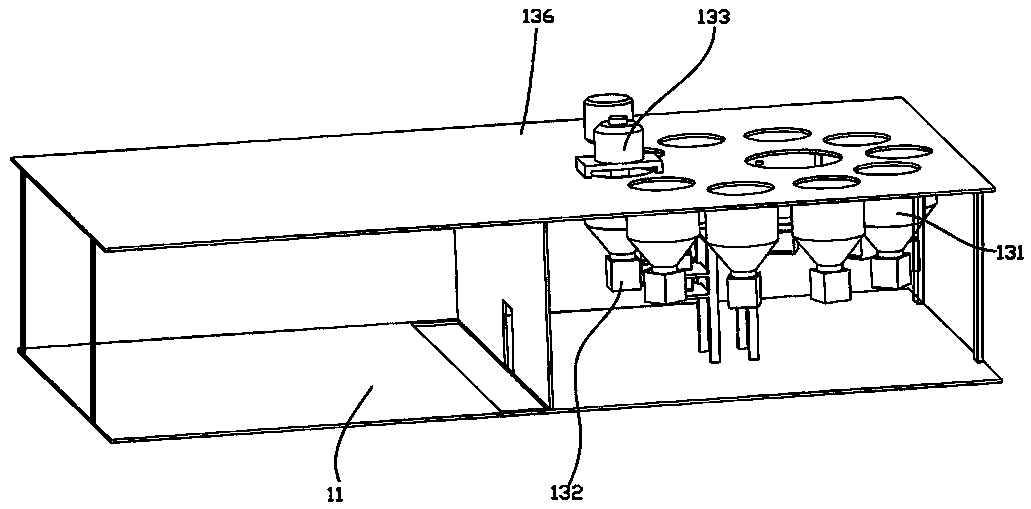

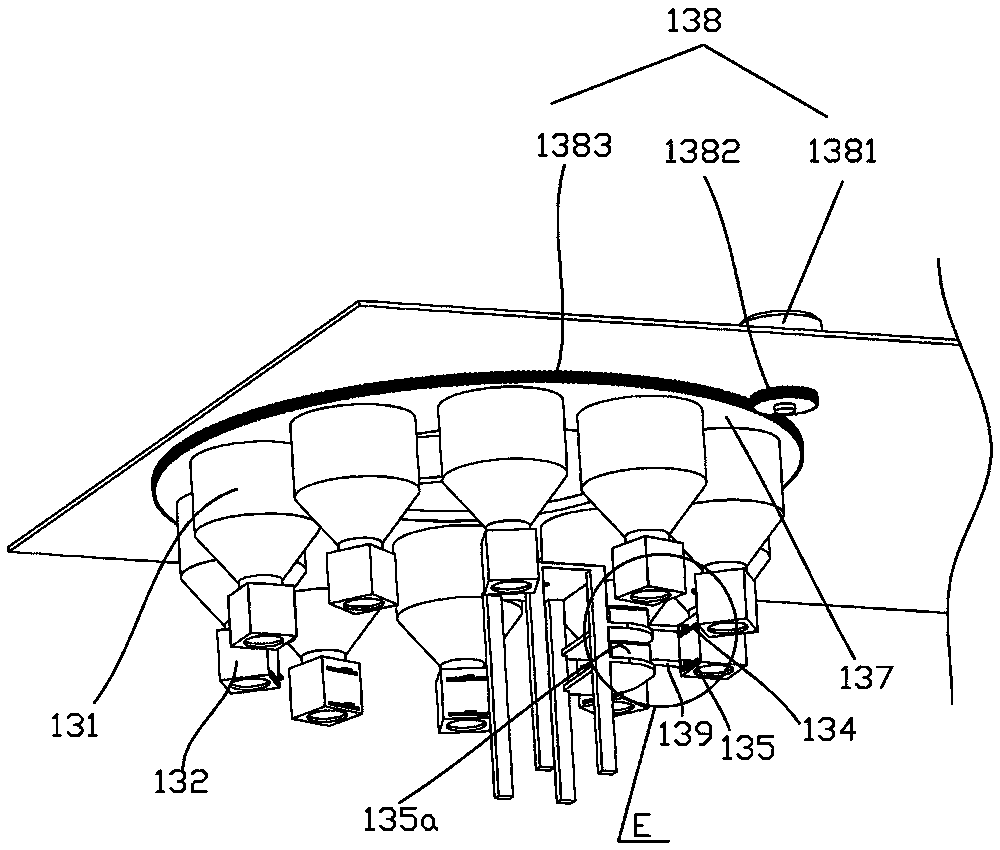

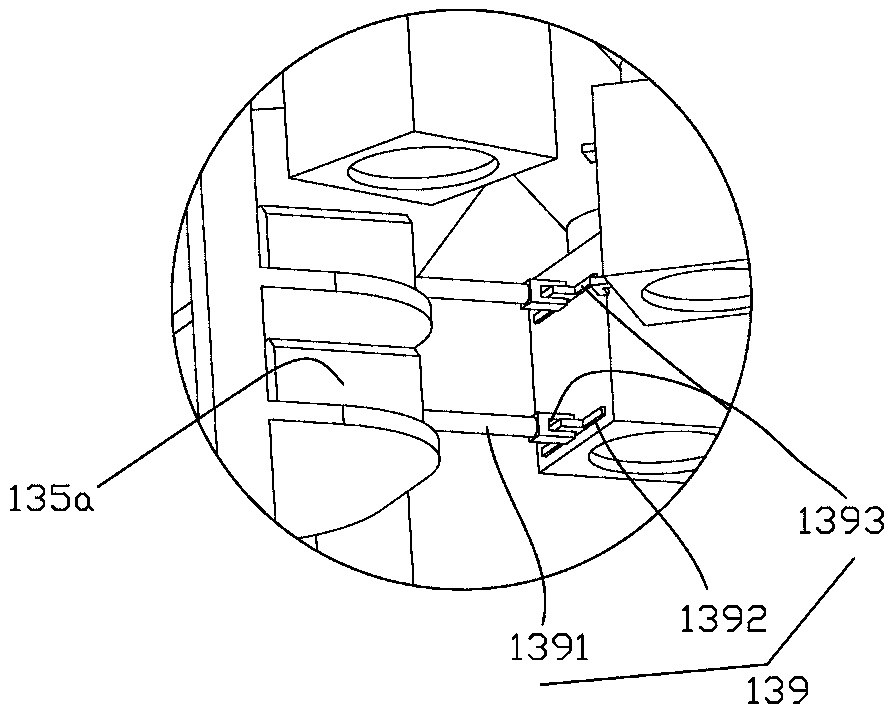

[0019] Such as Figure 1-5 As shown, a steamed stuffed bun stuffing device with multiple fillings includes a raw material loading base plate 136 installed on the frame 11, a stuffing storage box installation turntable 137 installed on the raw material loading base plate 136, and a rotating disk 137 installed on the raw material loading base plate 136. A plurality of stuffing boxes 131 for storing fillings that are annularly distributed on the stuffing box installation rotating disk 137, and a stuffing switching device 138 for selecting and switching stuffing boxes 131, also include and each described The stuffing metering box 132 connected to the bottom of the stuffing box 131 for controlling the amount of fillings to be delivered each time, the filling material pushing mechanism 133 for promoting and sending the filling into the stuffing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com