High-effective-capacity water mist grinding material mixing cylinder

A technology of effective volume and mixing cylinder, which is applied in the field of sandblasting machines, can solve the problems of longer sandblasting time and lower sandblasting efficiency, and achieve the effects of reducing the frequency of adding materials, improving sandblasting efficiency, and large effective use volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

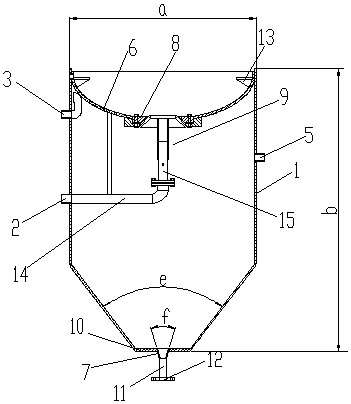

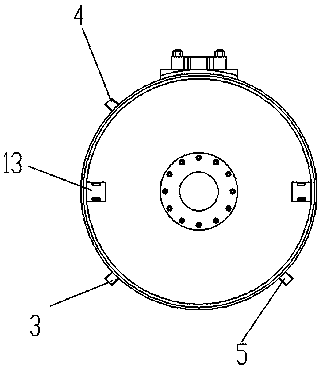

[0016] see Figure 1 to Figure 2 , the present invention is a water mist abrasive mixing cylinder with a large effective volume, comprising a water mist abrasive cylinder body 1, the total volume of the water mist abrasive cylinder body 1 is 1.0-1.8m³, and the water mist abrasive cylinder body 1 Bore and height ratio a:b is 1:1.5~2;

[0017] The top of the water mist abrasive cylinder body 1 is provided with a head 6, the head 6 is reversed, the outlet of the head 6 is provided with a valve seat 8, and the valve seat 8 is provided with a mushroom head valve 9, The valve seat 8 cooperates with the mushroom head valve 9, the lower end of the mushroom head valve 9 is an empty pipe, the water mist abrasive cylinder body 1 cylinder wall is provided with a water inlet 2, and the water inlet 2 is connected to the water inlet pipe 14. The water inlet pipe 14 is bent upwards to connect the inner casing 15 through the flange, and the inner casing 15 moves up and down in the empty pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com