Polyolefin/enzymatic-hydrolyzed lignin composite material and preparation method thereof

A technology for enzymatic hydrolysis of lignin and composite materials, applied in the field of polyolefin/enzymatic hydrolyzed lignin composite materials and their preparation, can solve the problems of complex steps, poor compatibility, poor mechanical properties of composite materials, etc., and improve toughness. and elastic modulus, excellent biodegradability, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) 100 grams of dried enzymatic lignin is crushed to obtain enzymatic lignin powder with a particle size of about 10 microns, and then 5 grams of polyethylene wax plasticizer is added to the enzymatic lignin powder to mix the two uniform, and then placed in an oven, treated at 60° C. for 15 hours to obtain dry enzymatic lignin pretreatment powder.

[0036] (2) 100 grams of the obtained enzymatic lignin pretreatment powder was mixed with 100 grams of injection-molded polypropylene pellets (PPK1008, Yanshan Petrochemical) and 150 grams of high-density polyethylene pellets, and then physically blended at 130°C , during the blending process, 10 grams of stearic acid and 30 grams of nano-calcium carbonate lubricant were added, and after 10 minutes of blending treatment, the cake was formed to obtain a polyolefin / enzymatic lignin composite material.

Embodiment 2

[0038] (1) After crushing 100 grams of dried enzymatic lignin to obtain enzymatic lignin powder with a particle size of about 100 microns, add 5 grams of maleic anhydride grafted polyethylene and 5 grams of palm to the enzymatic lignin powder Wax plasticizer, the three are mixed evenly, and then placed in an oven, treated at 70°C for 20 hours to obtain dry enzymatic lignin pretreatment powder.

[0039] (2) Mix 100 grams of the obtained enzymatic lignin pretreatment powder with 100 grams of low-density polyethylene pellets, then physically blend at 160° C., and add 20 grams of stearic acid during the blending process Calcium and 30 grams of 1000-mesh calcium carbonate powder lubricant, after blending for 15 minutes, the cake can be formed to obtain polyolefin / enzymolysis lignin composite material.

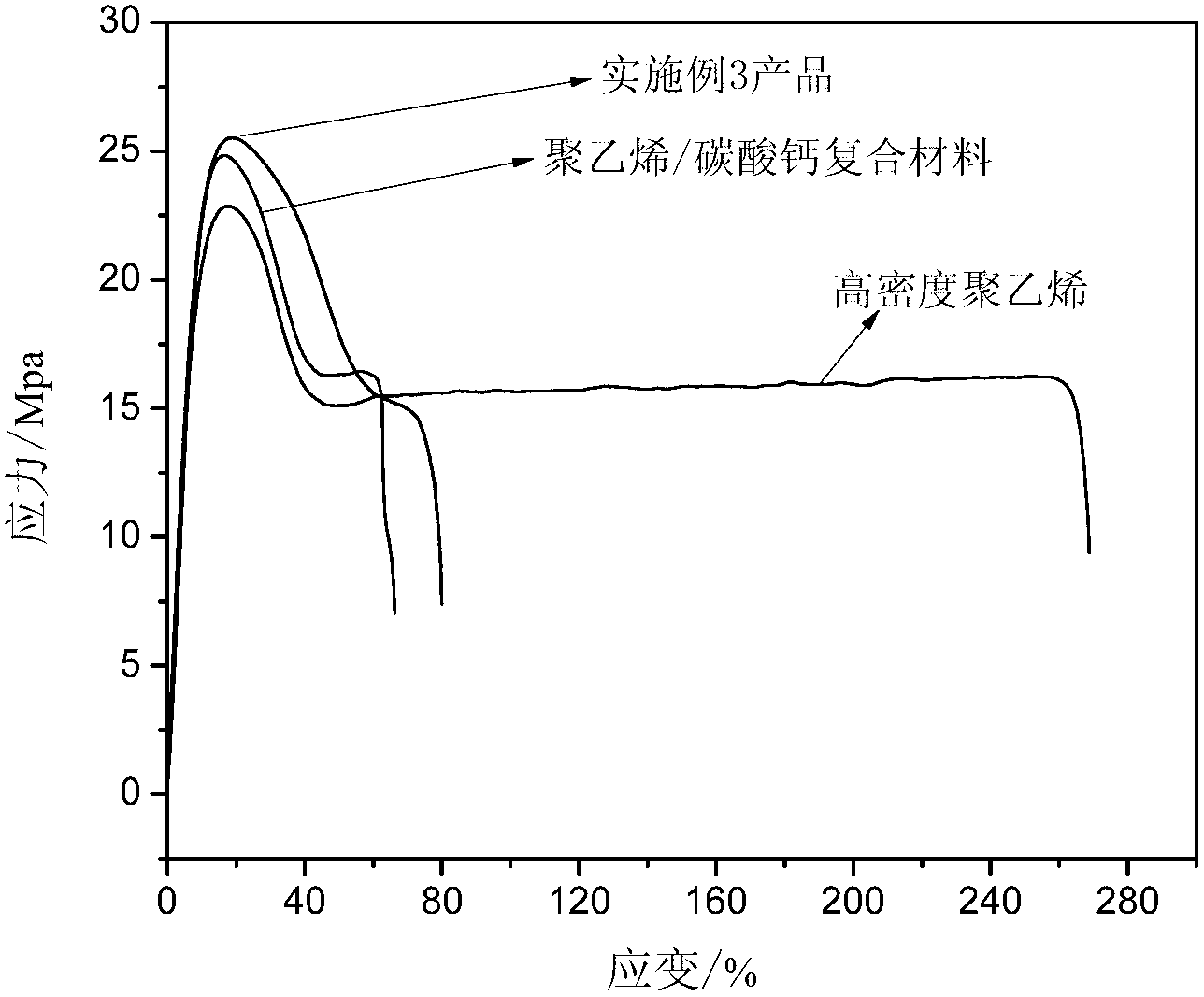

Embodiment 3

[0041] (1) 100 grams of dried enzymatic lignin is pulverized to obtain enzymatic lignin powder with a particle size of about 20 microns, and then 5 grams of dibutyl phthalate and 10 grams of cyclohexanol are added to the enzymatic lignin powder. Oxygenated soybean oil plasticizer, the three are mixed evenly, and then placed in an oven, treated at 85° C. for 18 hours to obtain dry enzymatic lignin pretreatment powder.

[0042] (2) Mix 100 grams of the obtained enzymatic lignin pretreatment powder with 200 grams of high-density polyethylene pellets, then physically blend at 150° C., and add 15 grams of stearic acid during the blending process Zinc and 45 grams of 500 mesh calcium carbonate powder lubricants, after blending for 20 minutes, the cake can be formed to obtain a polyolefin / enzymolysis lignin composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com