Patents

Literature

35results about How to "Reduce feeding frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

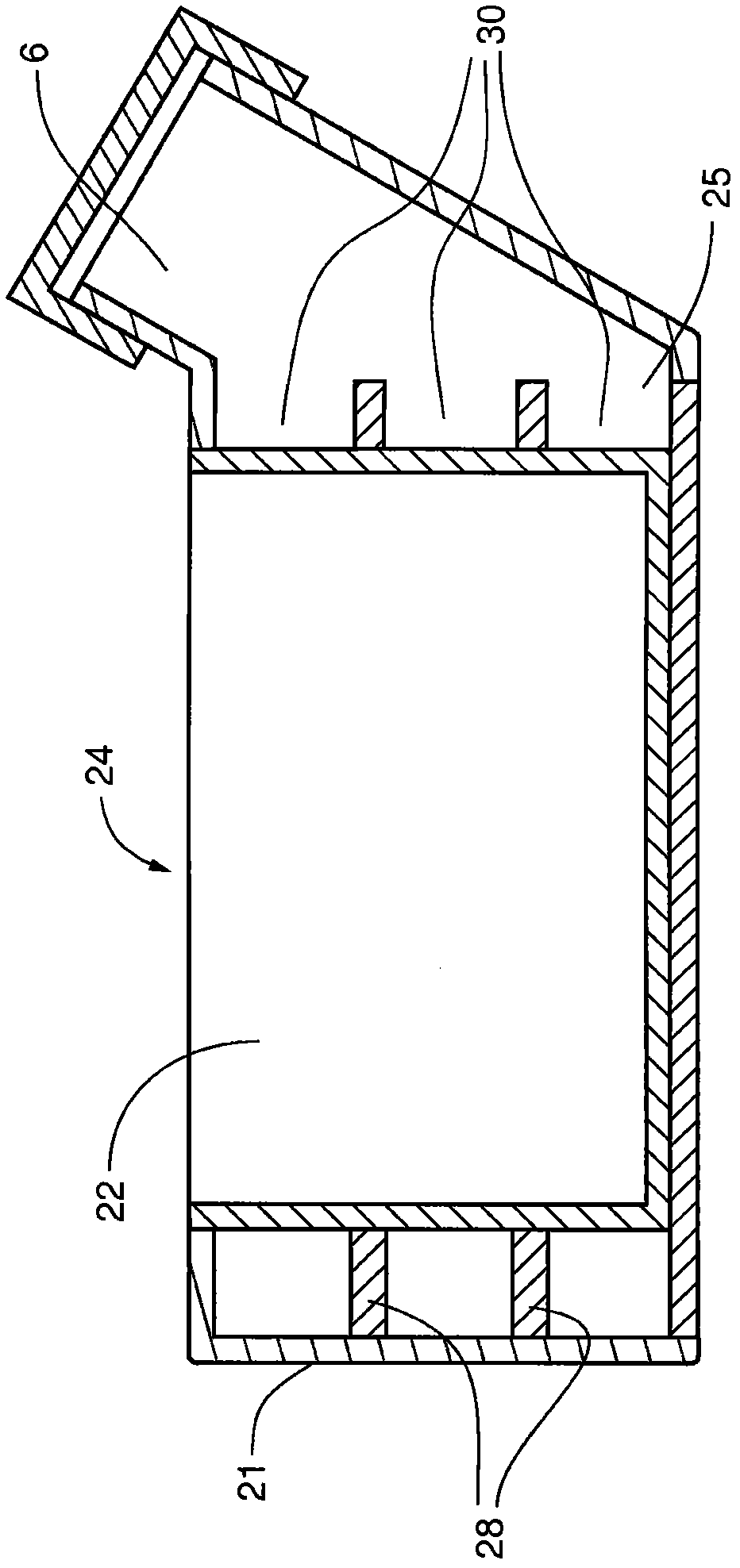

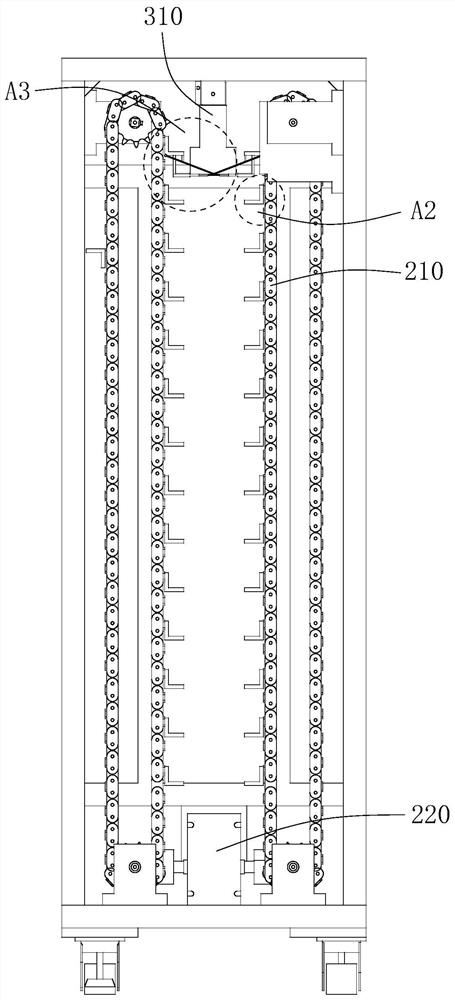

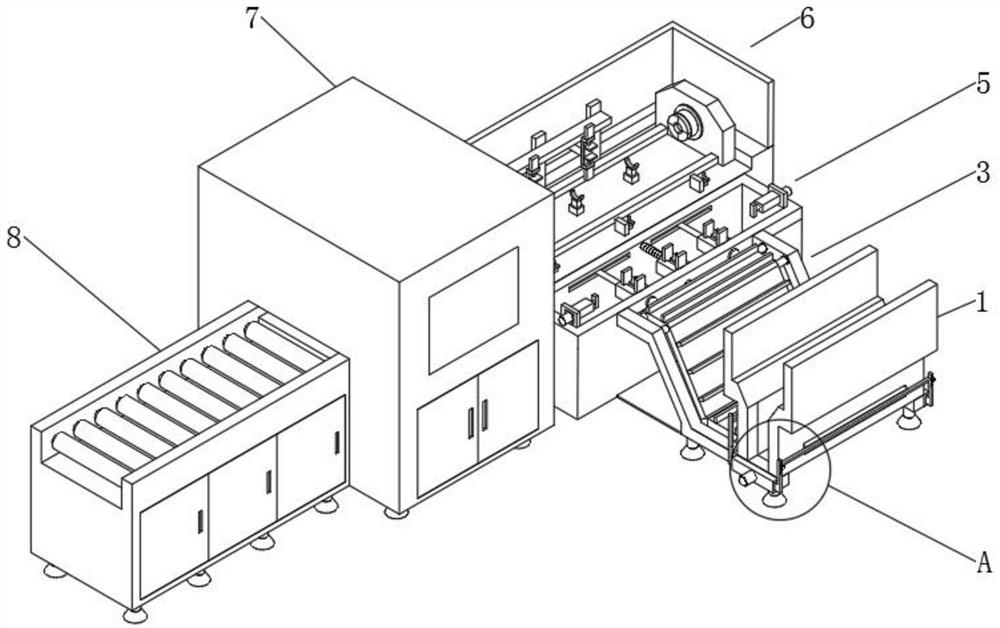

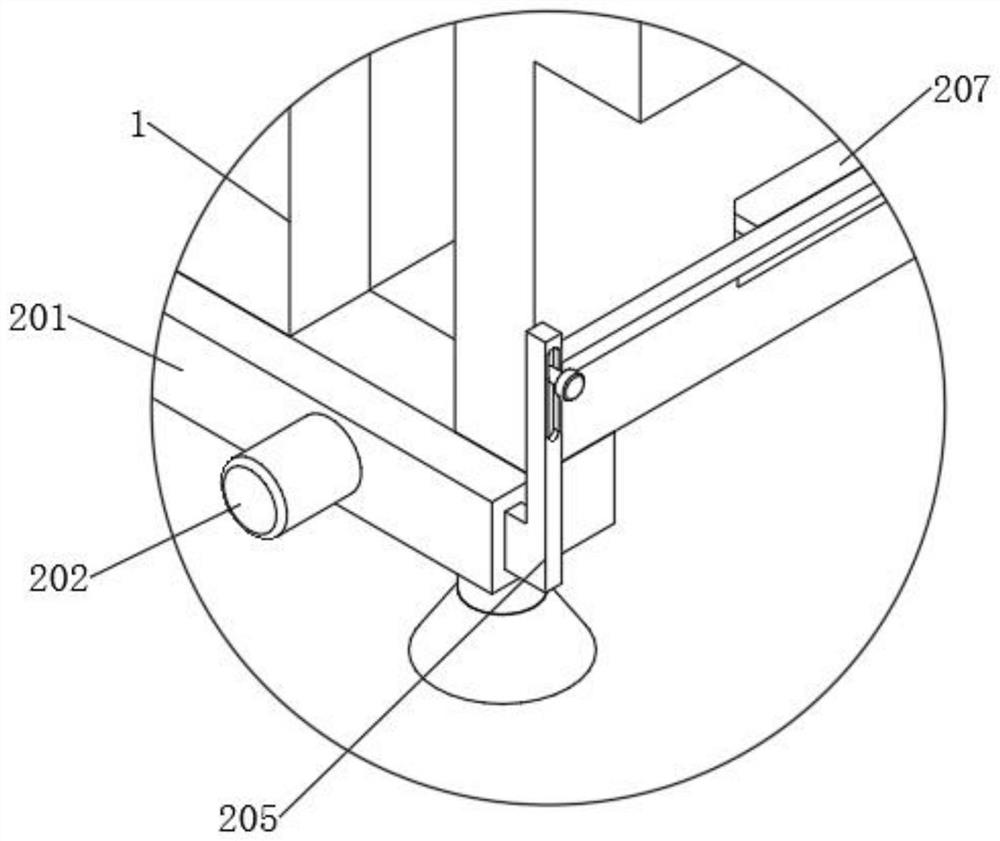

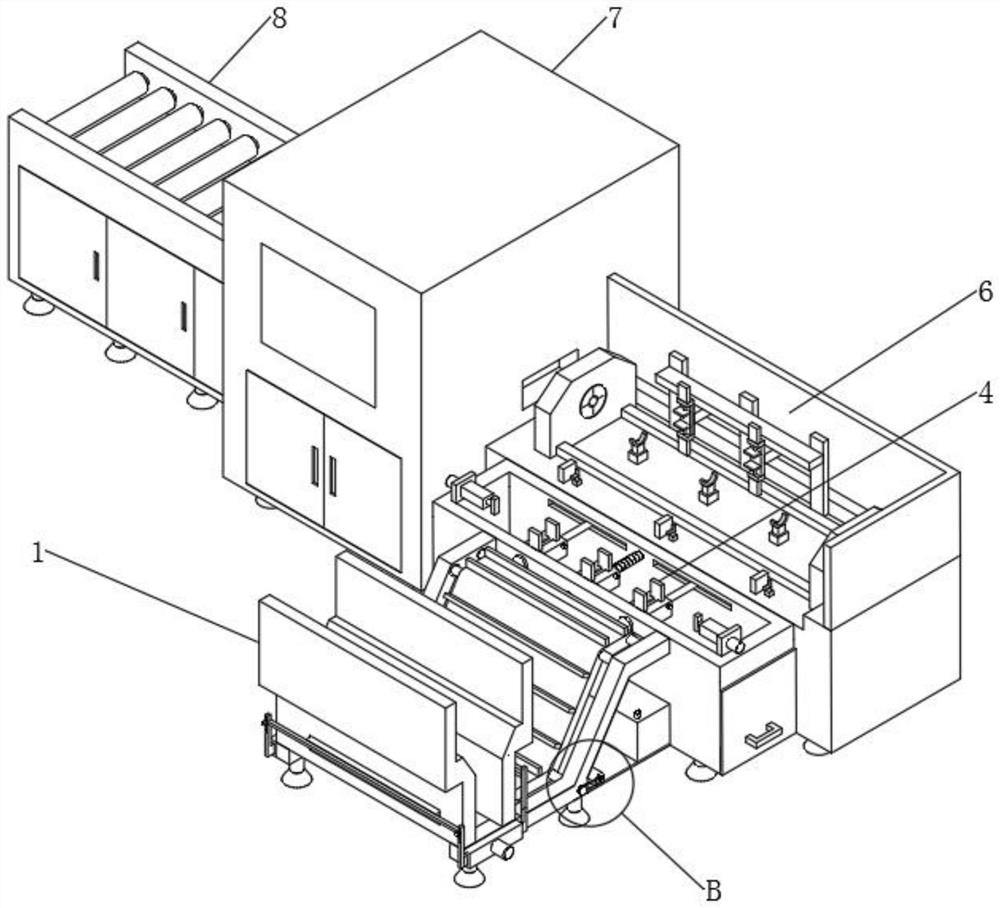

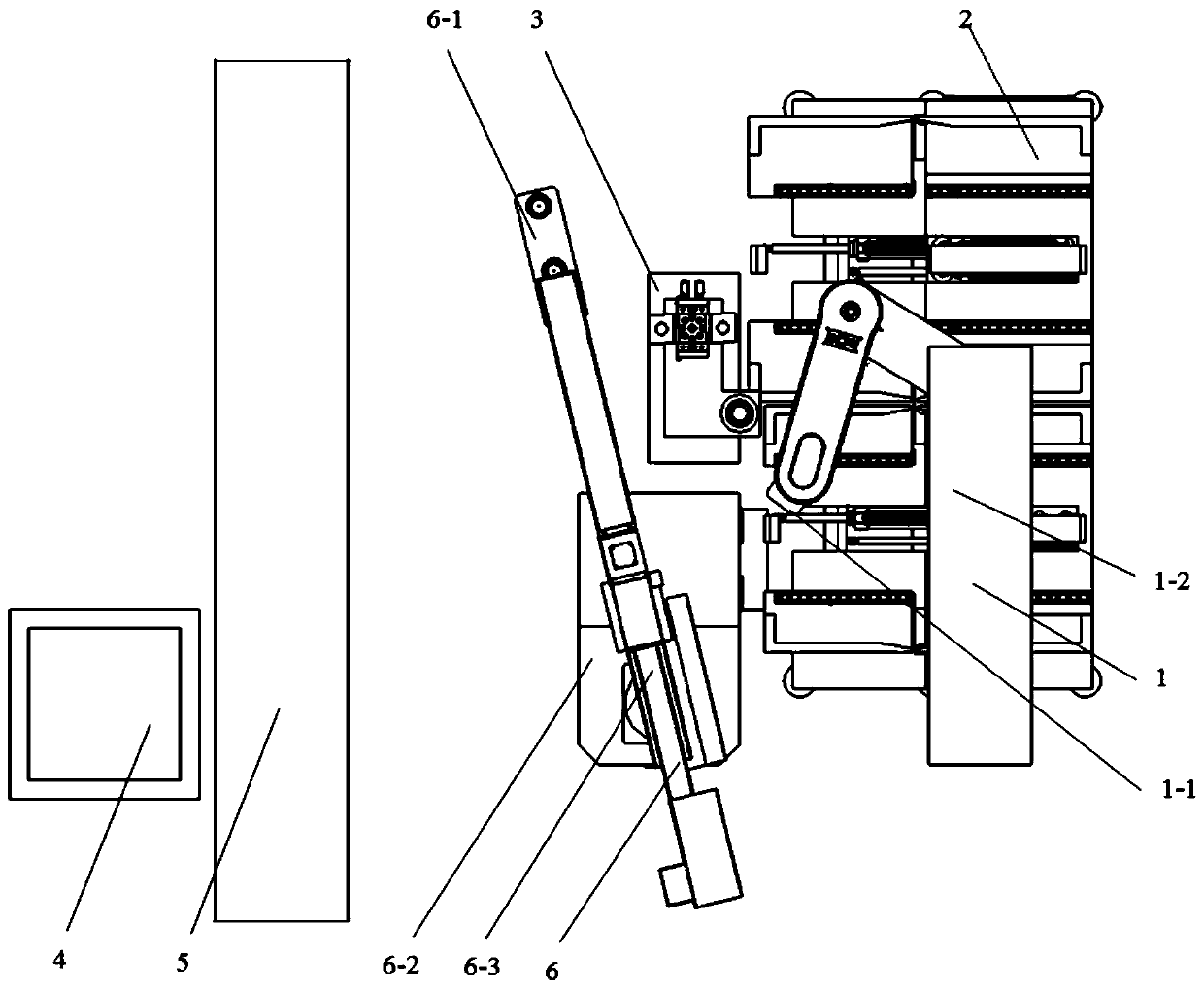

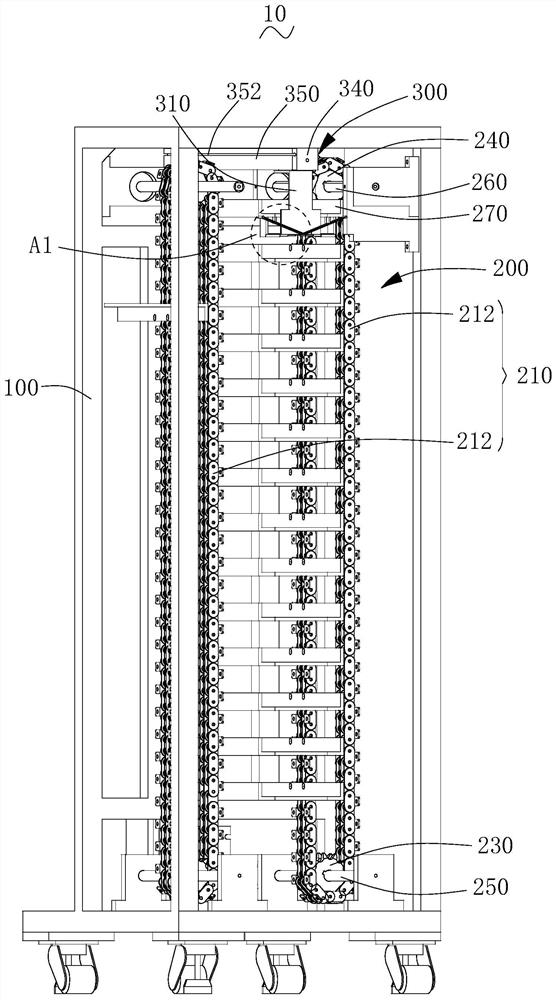

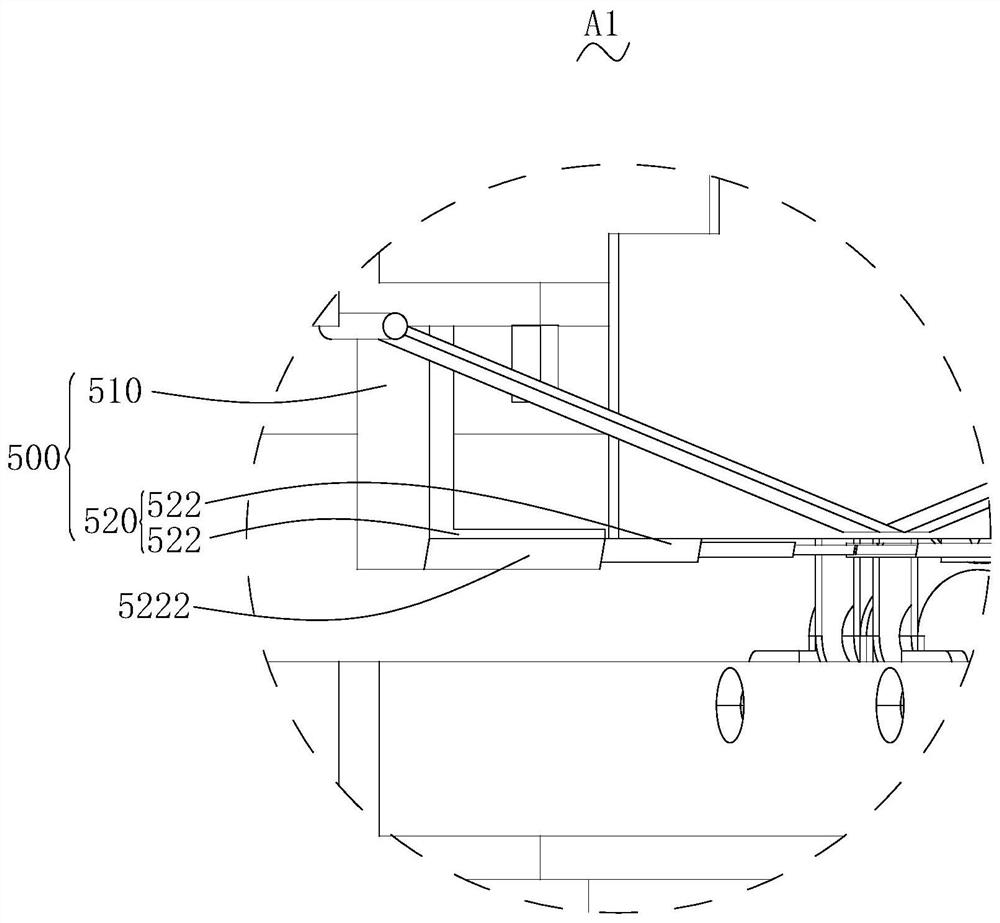

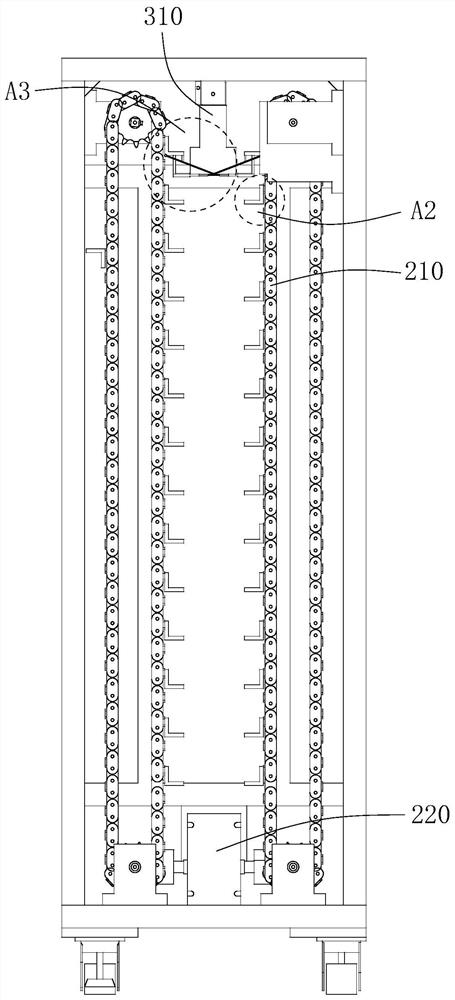

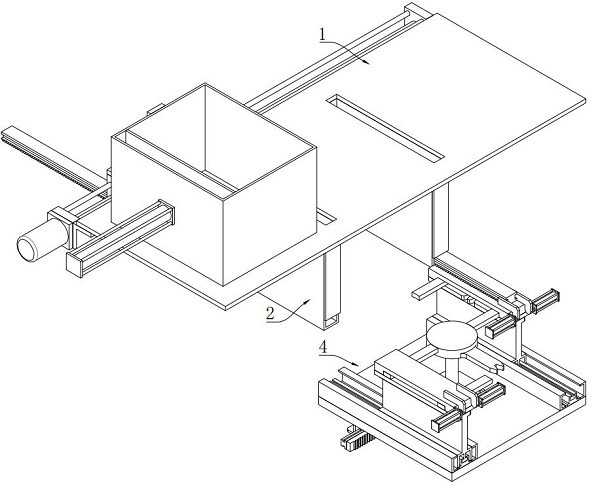

Material box alternate conveying device for IC detection

ActiveCN114426196AReduce the frequency of placingReduce work intensityDe-stacking articlesConveyor partsEngineeringControl theory

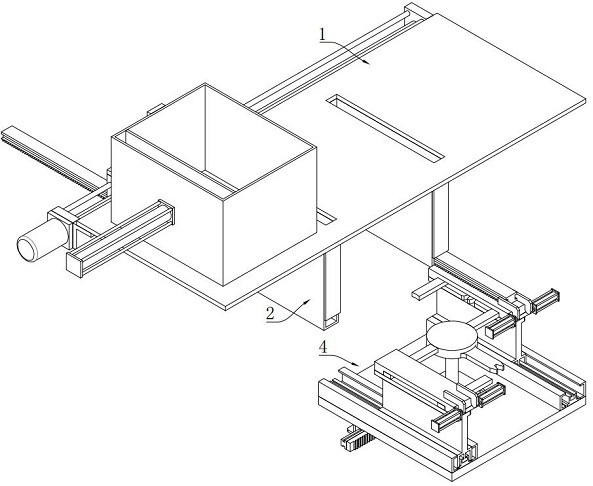

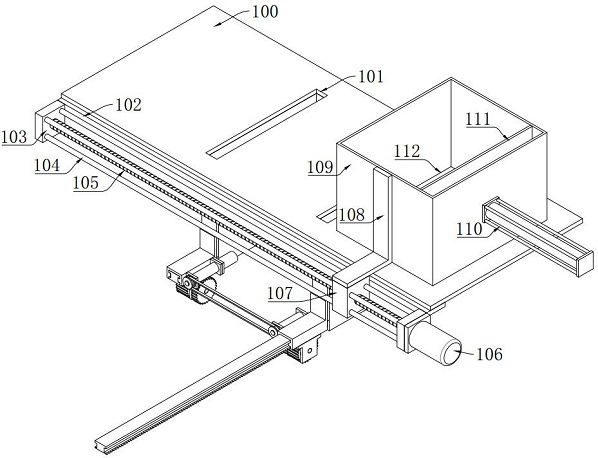

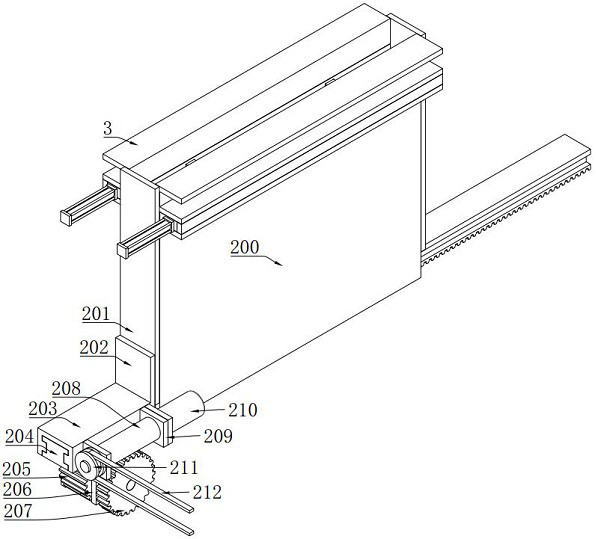

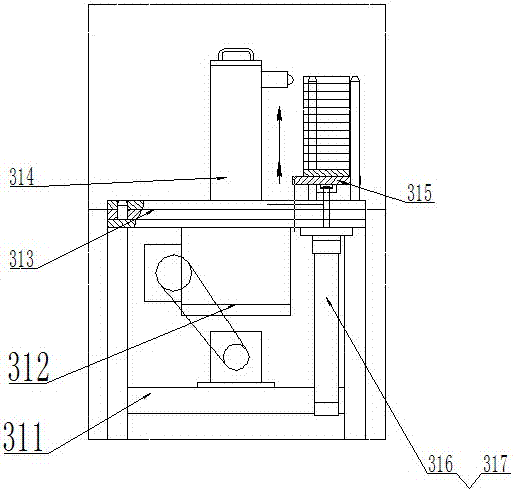

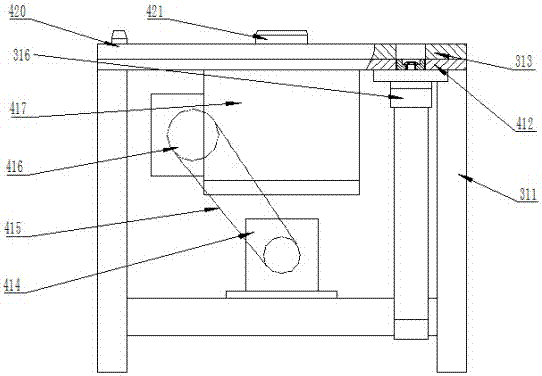

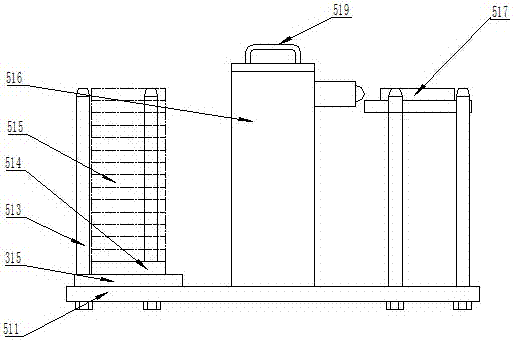

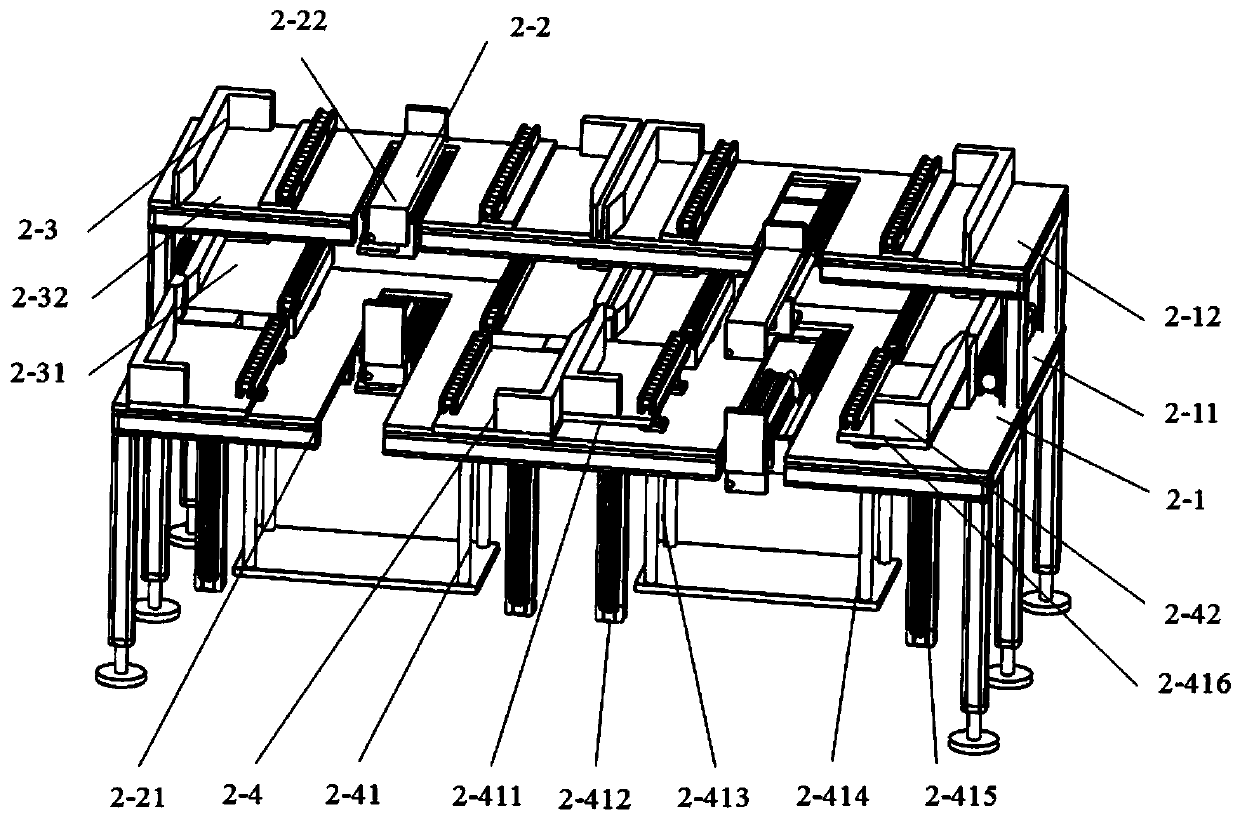

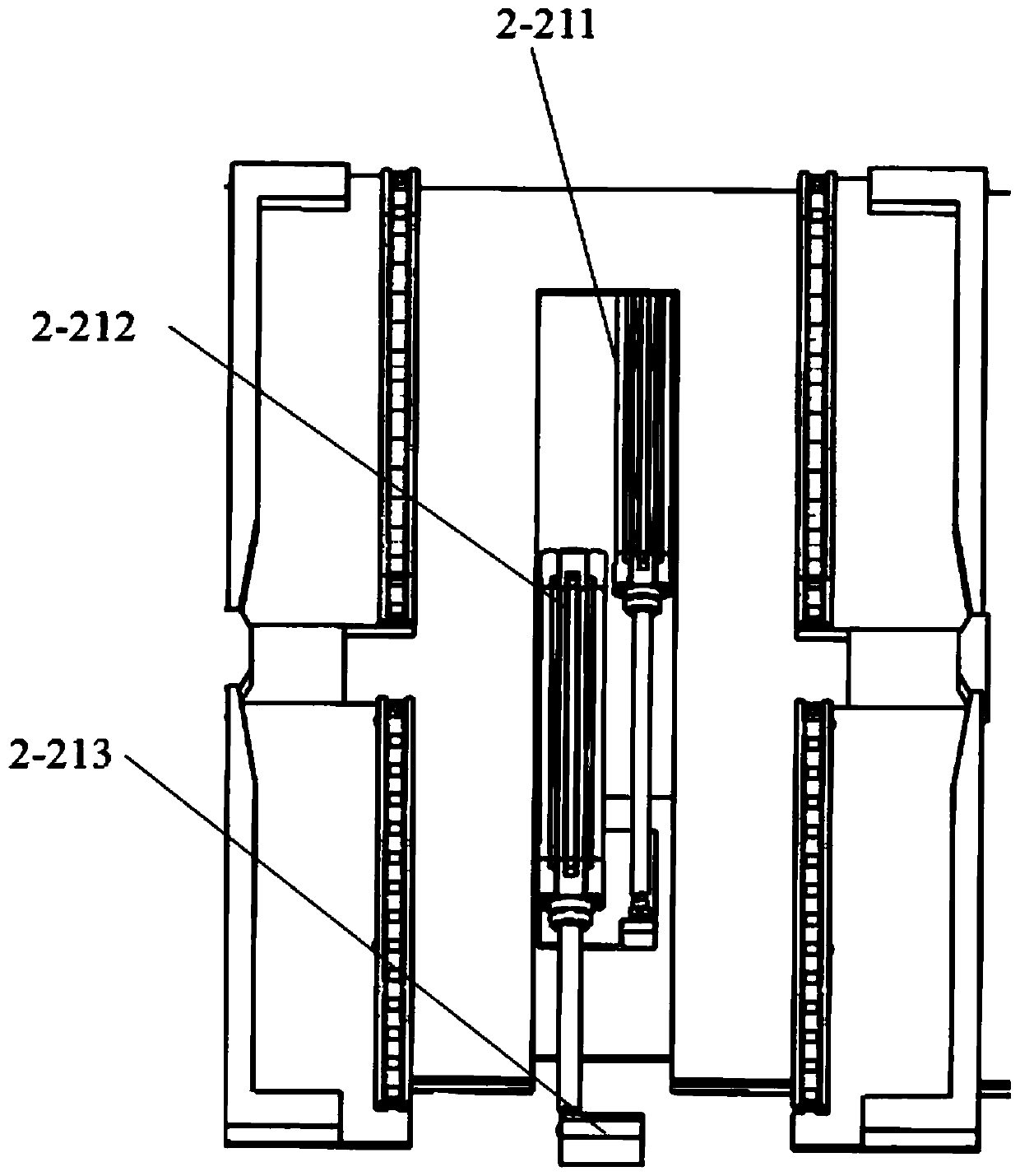

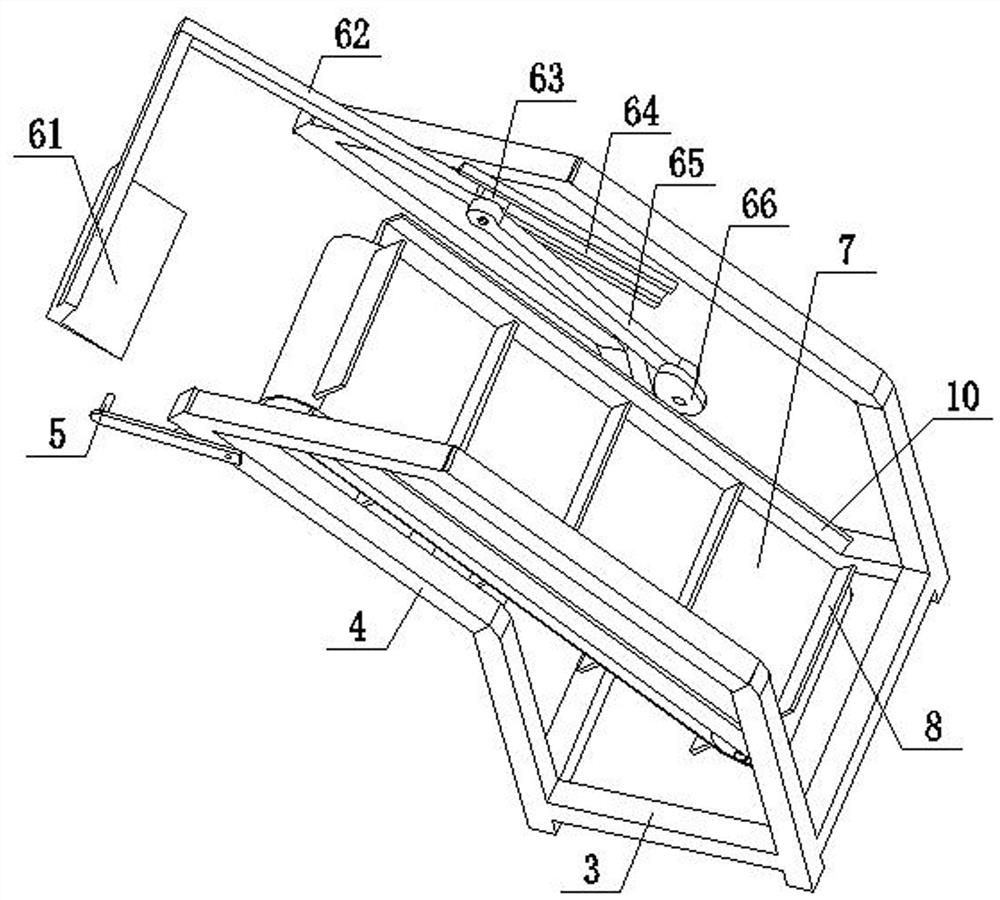

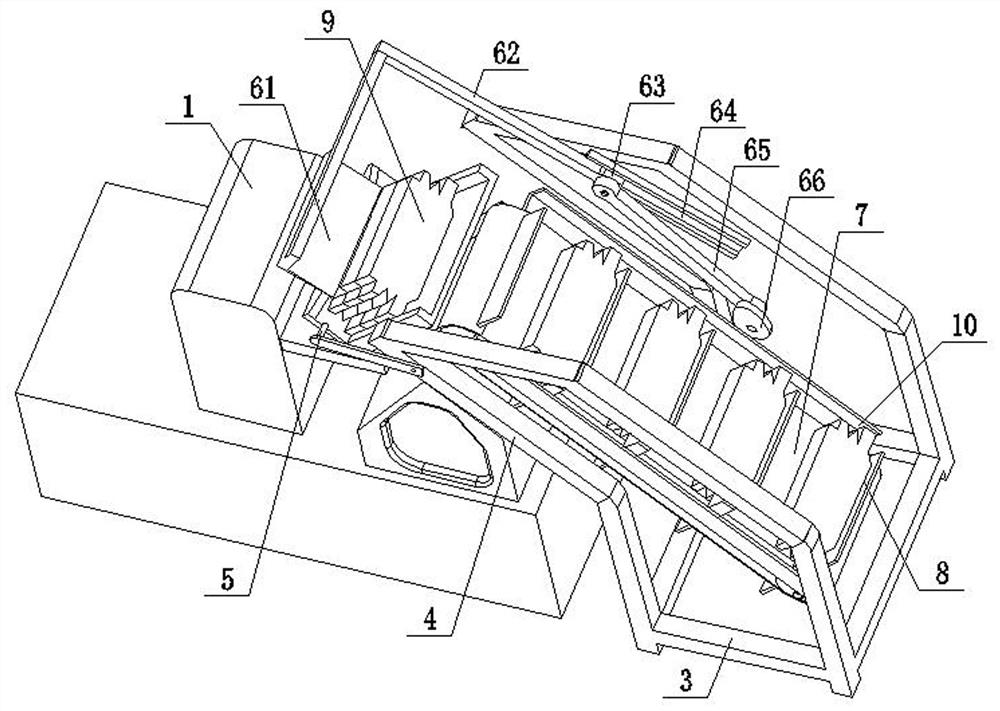

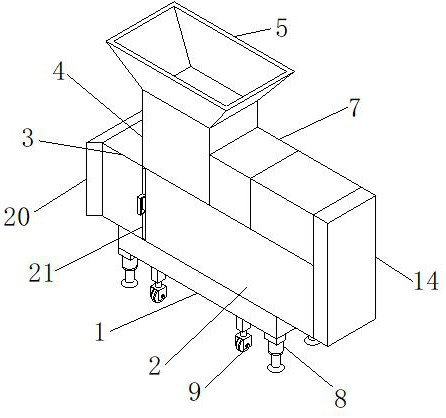

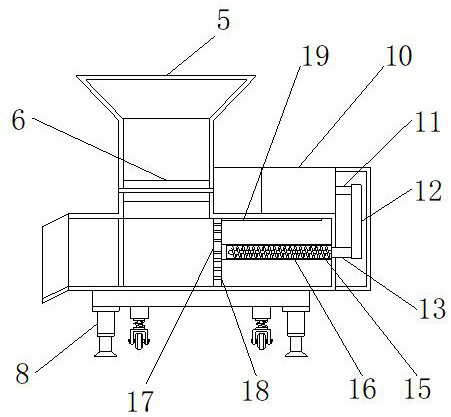

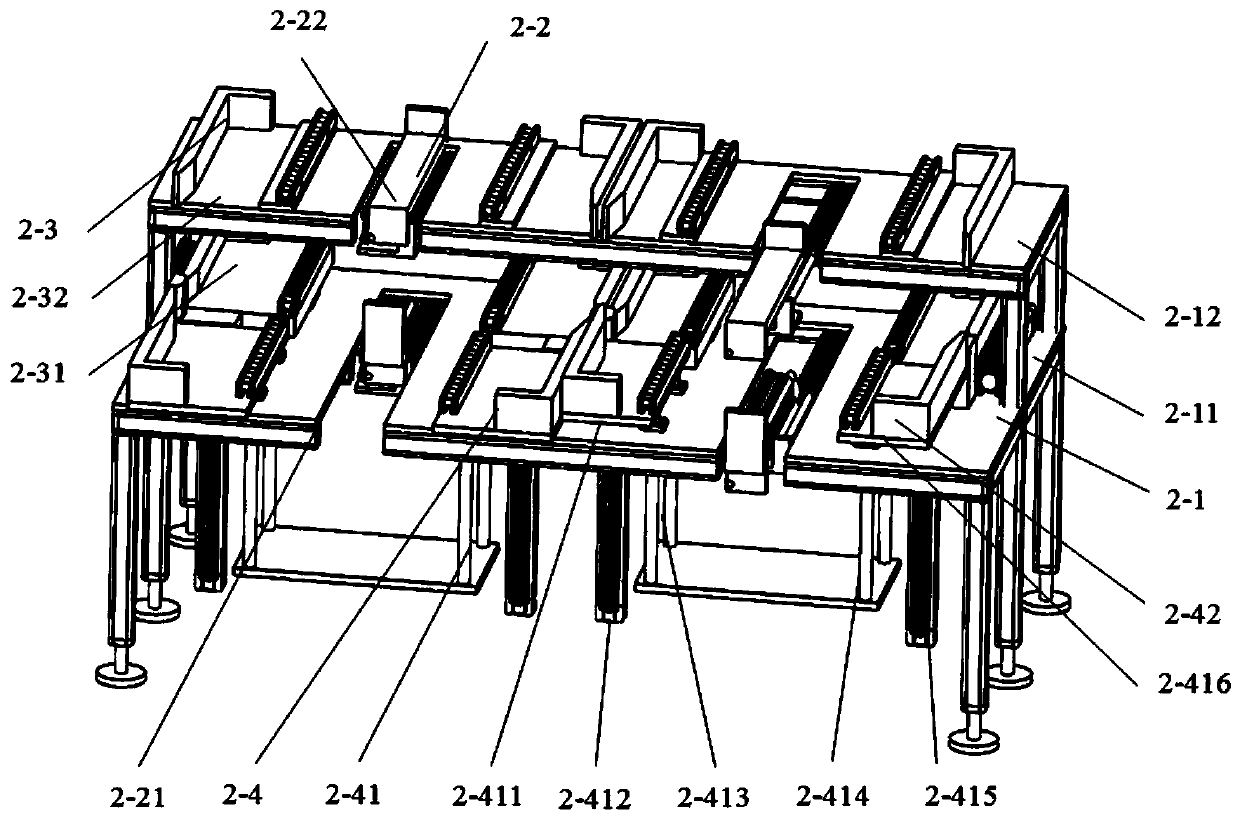

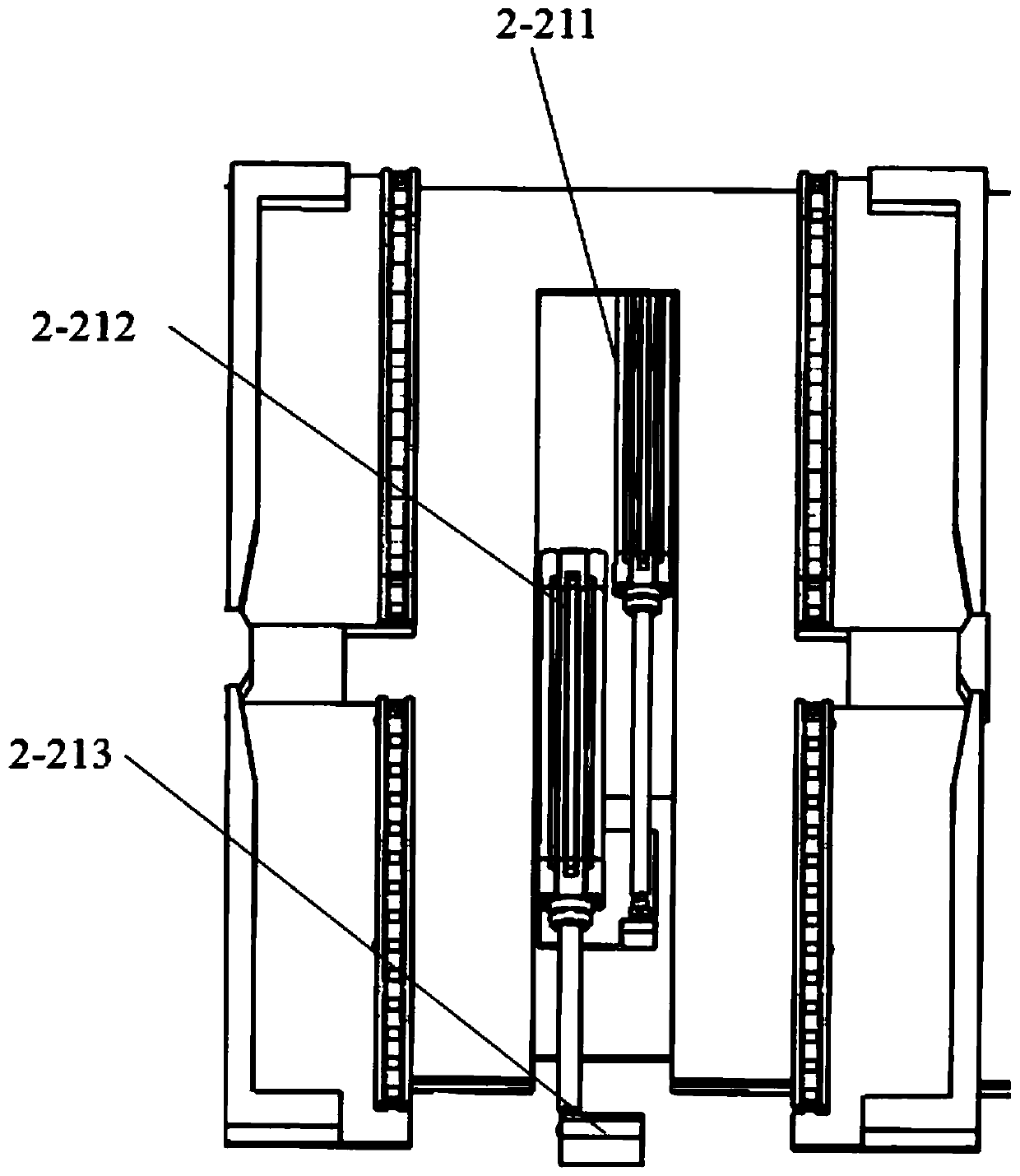

An alternative conveying device for material boxes for IC (integrated circuit) detection belongs to the related technical field of IC detection and comprises a feeding mechanism, a discharging mechanism, a lower blocking mechanism and a loading mechanism. The number of the discharging mechanisms is two, the discharging mechanisms are arranged at the lower end of the feeding mechanism, the number of the lower blocking mechanisms is four, every two lower blocking mechanisms are arranged at the upper end of one discharging mechanism, and the feeding mechanism is arranged at the discharging ends of the lower ends of the discharging mechanisms. When IC detection is carried out through the feeding mechanism, the discharging mechanism, the lower blocking mechanism and the feeding mechanism, alternate automatic feeding operation of material boxes filled with IC is conveniently carried out, multiple rows of material boxes can be stored at a time, therefore, the material box placing frequency is reduced, the working intensity of operators is reduced, meanwhile, through the alternate feeding mode, the working efficiency is improved, and the working efficiency is improved. And the feeding efficiency is obviously improved.

Owner:四川明泰微电子科技股份有限公司

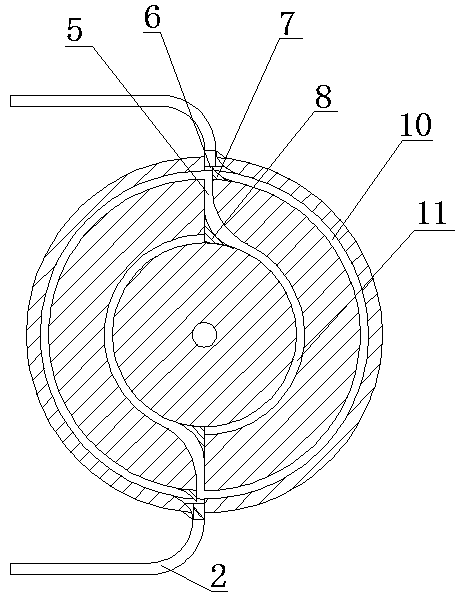

Stereoscopic rotary feeding device

PendingCN106966121AReduce labor intensitySmall footprintControl devices for conveyorsStacking articlesRotary stageProduction line

The invention relates to the technical field of feeding of processing and assembling production lines, in particular to a stereoscopic rotary feeding device. The stereoscopic rotary feeding device is characterized in that a rotating table is mounted on a rotating platform of a rotating table support and is driven by a rotating platform drive part to rotate around the center, a part revolving disc is mounted on the rotating table through a positioning shaft, and a lifting cylinder and a descending cylinder are mounted below the rotating table; the part revolving disc is arranged on the rotating table, the lifting cylinder and the descending cylinder drive lifting of a tray of the part revolving disc, and a lifting or descending position is controlled by a to-be-machined workpiece monitor unit and a machined workpiece monitor unit; the part revolving disc comprises a revolving disc base plate, a central lifting pipe is arranged in the center of the revolving disc base plate, positioning rods are arranged on the periphery of the central lifting pipe, the tray is fixed on the positioning rods, and a positioning disc is mounted on the tray. The stereoscopic rotary feeding device is simple in structure, economical and applicable, sufficiently utilizes stereoscopic space, occupies a very small area, has quite high installed capacity and can realize manual supplementary feeding in different places, combined preassembly and the like.

Owner:无锡津九合盛机床有限公司

Anti-tilting transportation device for bearing machining

InactiveCN112644569APrevent slippageReasonable structural designSupporting partsHand carts with multiple axesStructural engineeringMechanical engineering

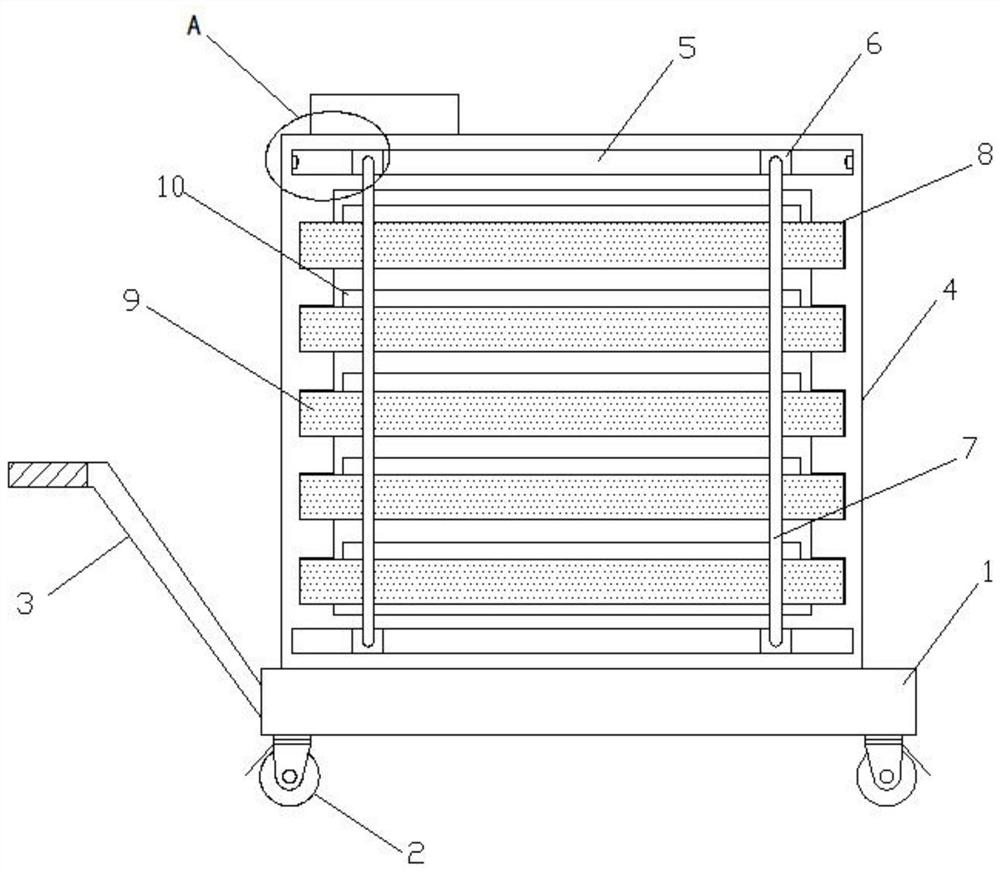

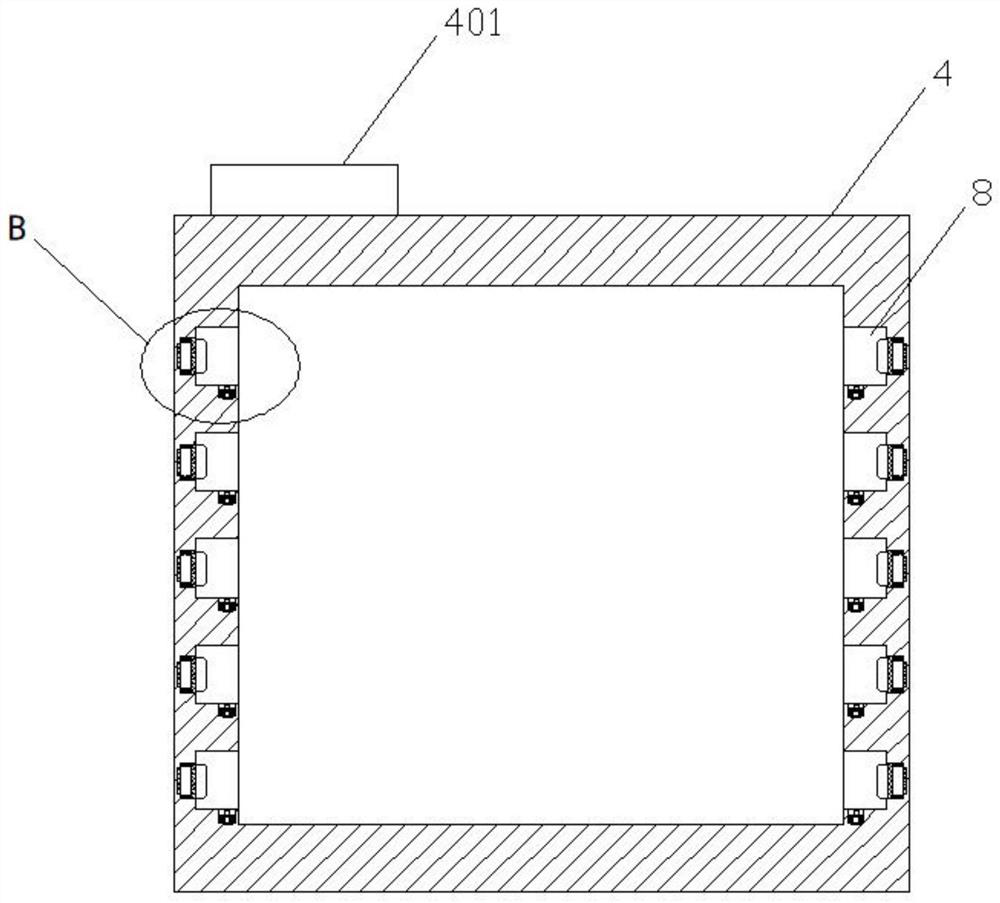

The invention discloses an anti-tilting transportation device for bearing machining. The anti-toppling conveying device comprises a base frame, moving wheels are connected to the four corners of the bottom of the base frame, a push rod is connected to the left side wall of the base frame, a conveying shell is connected to the top of the base frame, the front end of the conveying shell is open, sliding grooves are formed in the upper side and the lower side of an opening of the conveying shell, and two sliding blocks are slidably connected into each sliding groove. A stop lever is connected between the upper and lower sliding blocks, a plurality of guide grooves are formed in the inner side wall of the transportation shell, the left and right guide grooves are symmetrically formed, and a bearing table is inserted between the left and right guide grooves; the anti-tilting transportation device is reasonable in structural design, the feeding frequency is reduced, the production efficiency is improved, machined parts are effectively prevented from inclining and falling off in the transportation process, the discharging difficulty is reduced, and use is more convenient.

Owner:宜都红花夜明珠轴承制造有限公司

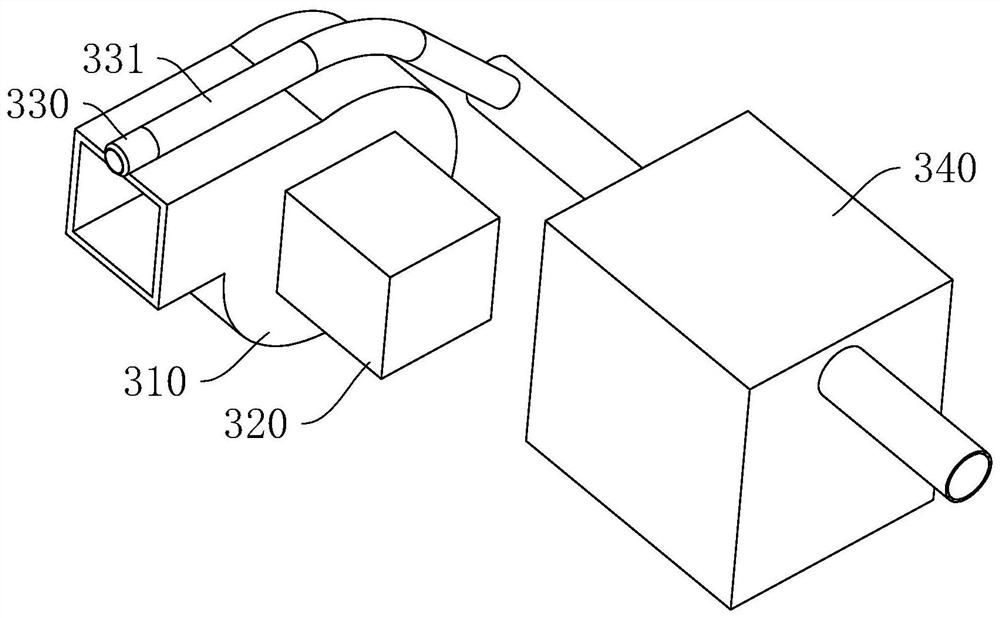

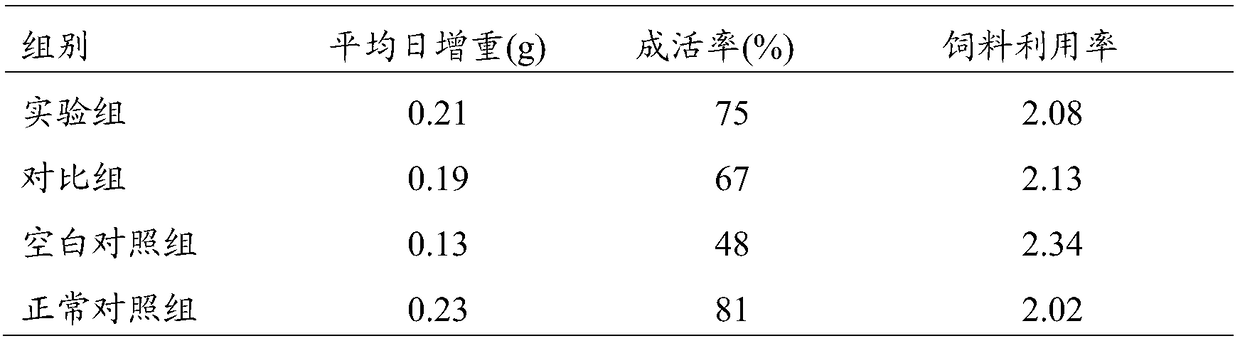

Ecological aquaculture method for sea horses

InactiveCN104381172AQuiet and stable growing environmentNo side effectsClimate change adaptationAnimal feeding stuffFiltrationOxygen

The invention provides an ecological aquaculture method for sea horses. The ecological aquaculture method comprises the following steps of adding seawater which is subjected to filtration, sedimentation and regulation into a plastic barrel: the salinity of the seawater is 2.0-2.8 percent, the pH is 7.6-8.5, the oxygen dissolving amount is greater than 5mg / L, the liquid level is 70-80cm, and the temperature is 20-30 DEG C; feeding seaweeds into the plastic barrel, and keeping the fresh weight density of the seaweeds to be 1-3kg / m<3>; feeding living baits into the plastic barrel; spraying microorganism preparations; feeding young sea horses. Compared with an existing aquaculture technology, the ecological aquaculture method for the sea horses has the advantages that by the method for sea horse aquaculture, the environmental factors can be stabilized and controlled, the large-scale industrial production is facilitated, the feeding frequency of baits is reduced, the production efficiency is improved, the survival rate of the sea horses is guaranteed, and the economical benefit is high.

Owner:SUZHOU CITY XIANGCHENG DISTRICT SHENGHU SPECIAL CULTIVATION SPECIALIZED COOP

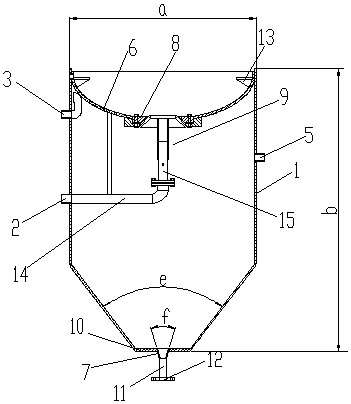

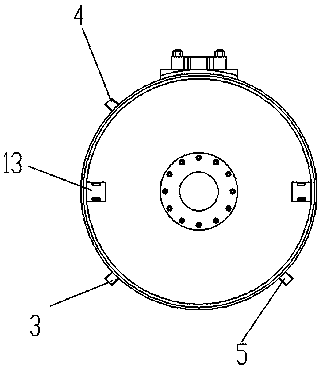

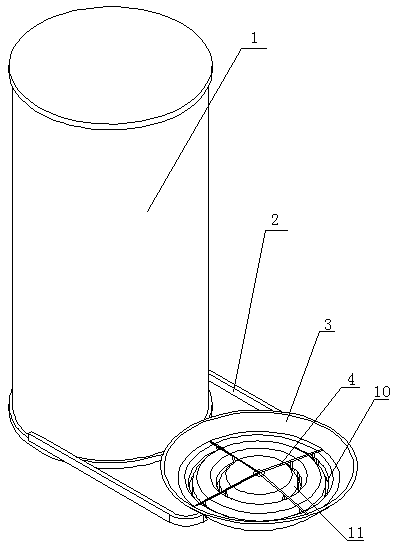

High-effective-capacity water mist grinding material mixing cylinder

PendingCN108479598AEffective use of large volumeReasonable structureTransportation and packagingMixersSand blastingEngineering

The invention relates to a high-effective-capacity water mist grinding material mixing cylinder. The high-effective-capacity water mist grinding material mixing cylinder comprises a water mist grinding material cylinder body, wherein the total capacity of the water mist grinding material cylinder body is 1.0-1.8m<3>; the ratio of diameter a to height b of the water mist grinding material cylinderbody is 1: 1.5-2. The high-effective-capacity water mist grinding material mixing cylinder is reasonable in structure; the effective utilization capacity of the water mist grinding material cylinder is improved; the water mist grinding material mixing cylinder can continuously run for 2h; the material adding frequency is reduced; and the sand blasting efficiency can be effectively improved.

Owner:CHENGXI SHIPYARD +1

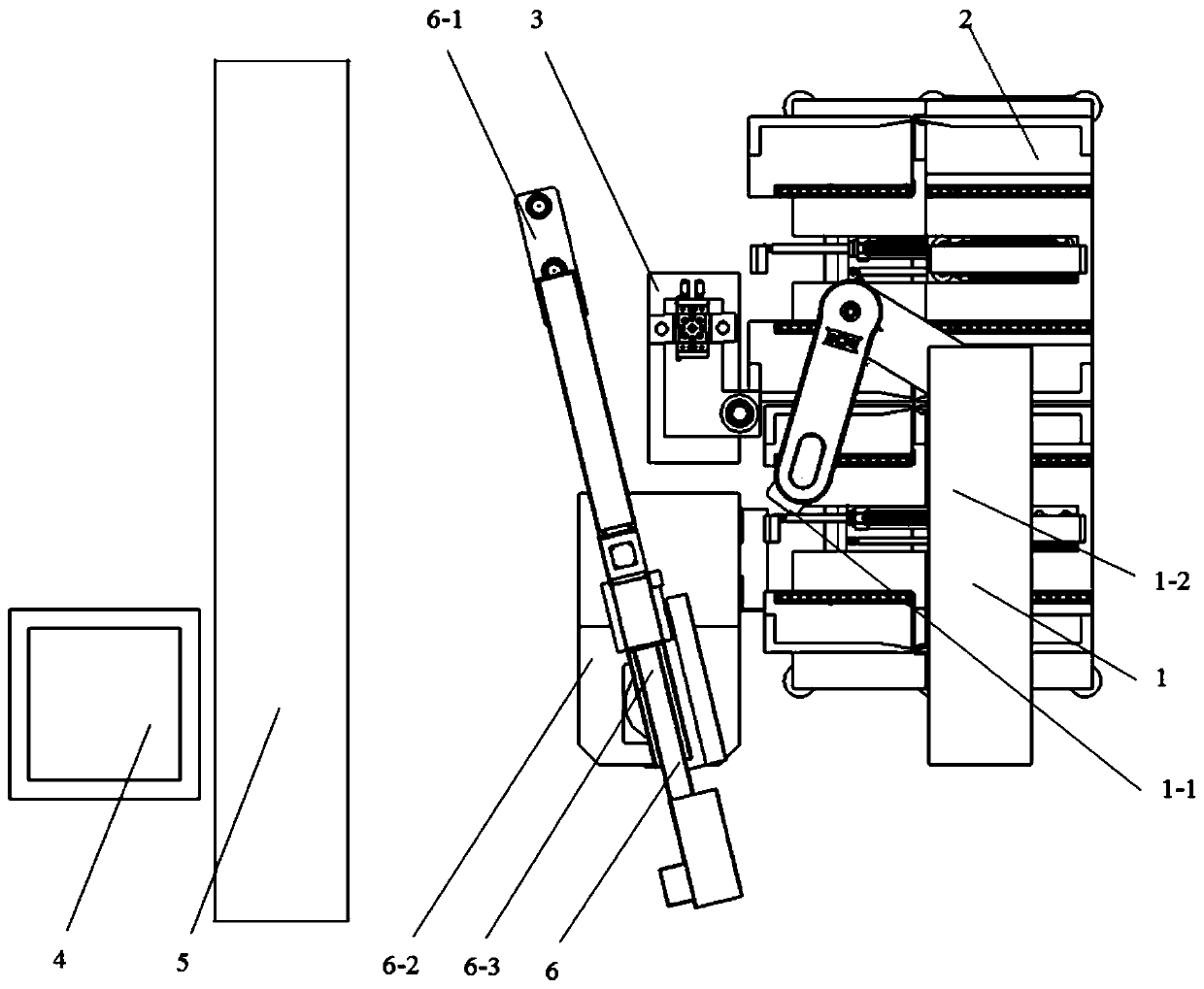

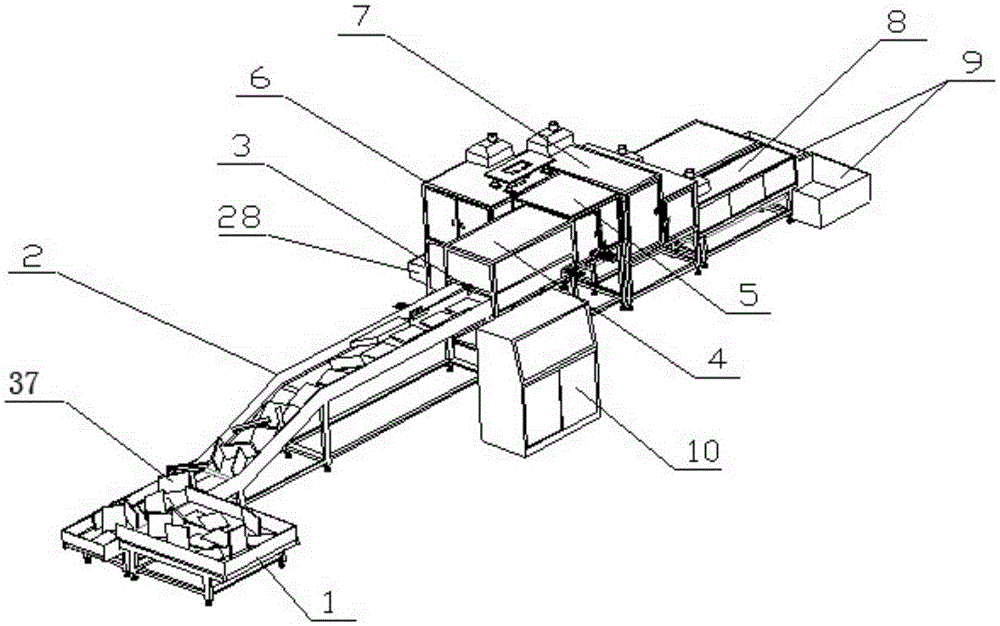

Automatic feeding and discharging device for perforating bullet assembling

The invention discloses an automatic feeding and discharging device for perforating bullet assembling. An assembling transferring mechanism is used for assembling materials and storing the materials temporarily; a four-shaft industrial robot is arranged between a material supplying and storing mechanism and the assembling transferring mechanism, and used for carrying the materials between the material supplying and storing mechanism and the assembling transferring mechanism; a punching robot is arranged between the assembling transferring mechanism and a hydraulic machine, and used for carrying the materials between the assembling transferring mechanism and the hydraulic machine; and a wall is arranged between the punching robot and the hydraulic machine. The feeding and discharging devicereduces the frequency of manual feeding and discharging, and is high in efficiency, wide in movement range, simple in structure and easy to control.

Owner:SICHUAN PETROLEUM PERFORATING EQUIP

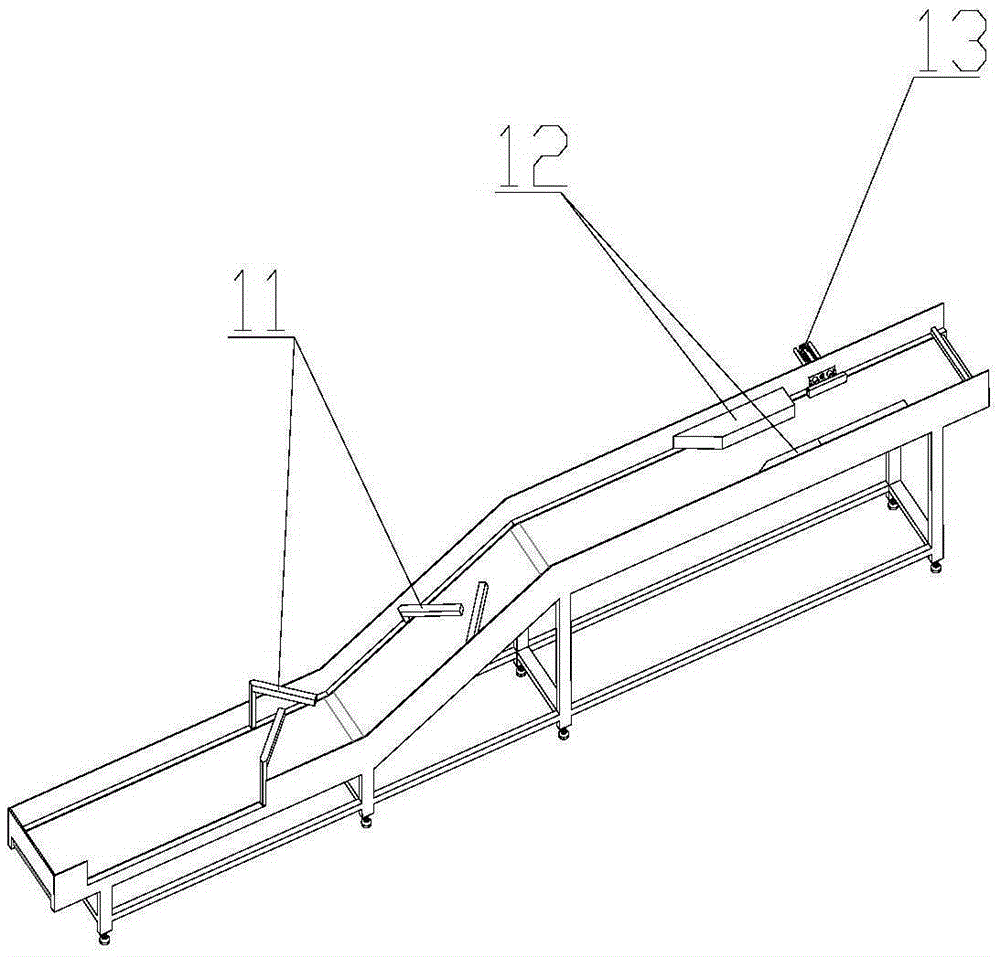

Scenting machine

PendingCN112931667AReduce work intensityImprove work efficiencyPre-extraction tea treatmentTea flavoringStructural engineeringMechanical engineering

The invention relates to a scenting machine which comprises a machine frame, a storage box and a feeding mechanism are arranged on the machine frame, the feeding mechanism comprises a first conveying belt, an adjusting frame, a second conveying belt, a material scattering frame, a rotating part and a driving assembly, the first conveying belt is rotationally installed on the machine frame, and the rotating part is installed on the machine frame and drives the first conveying belt to rotate; the adjusting frame is rotationally installed on the rack and connected with the first conveying belt; the second conveying belt is rotationally installed on the adjusting frame; the material scattering frame is horizontally installed on the storage box in a sliding mode and connected with the adjusting frame in a sliding mode; the material scattering frame is connected with the second conveying belt; and the driving assembly is installed on the storage box and connected with the material scattering frame. The tea leaf spreading device has the advantages that the contact area of a tea leaf layer and a fresh leaf layer is increased, fresh leaves are stacked on the tea leaf layer through the spreading frame, the working intensity of operators is reduced, the working efficiency of the operators is improved, and therefore the scented tea production efficiency is improved.

Owner:湖州嘉盛茶业有限公司

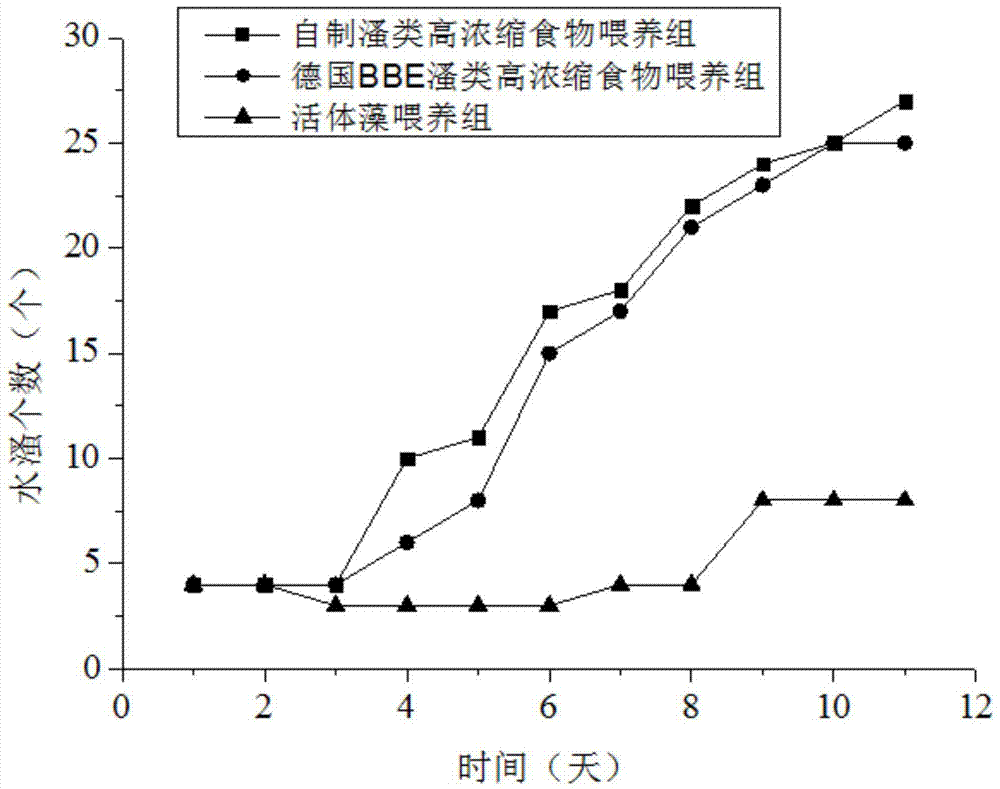

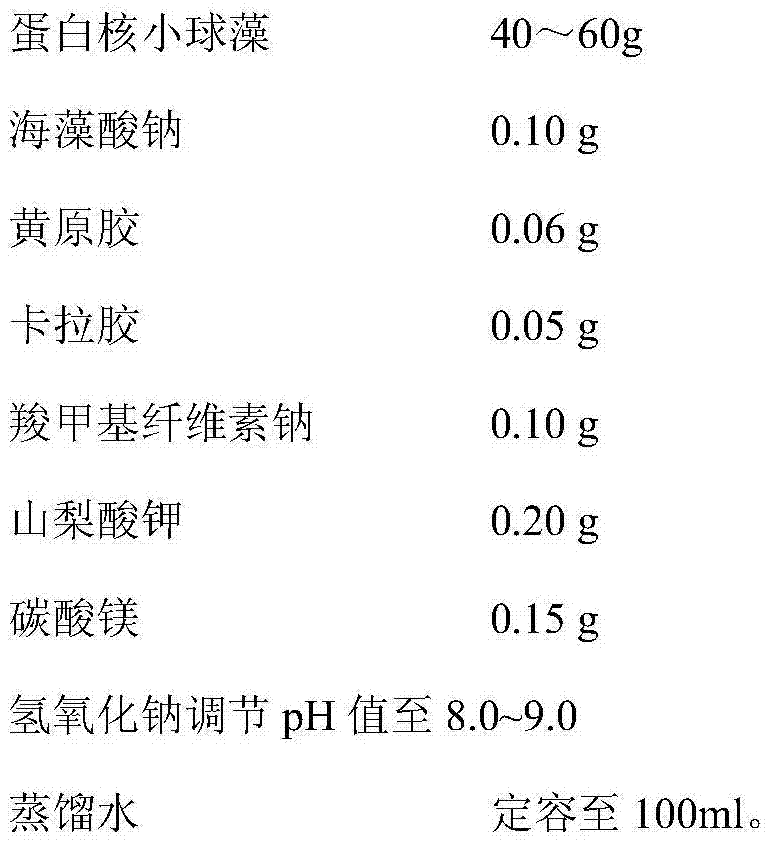

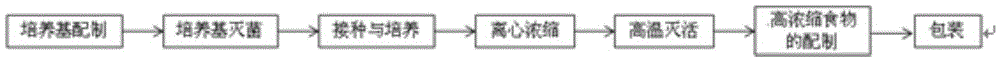

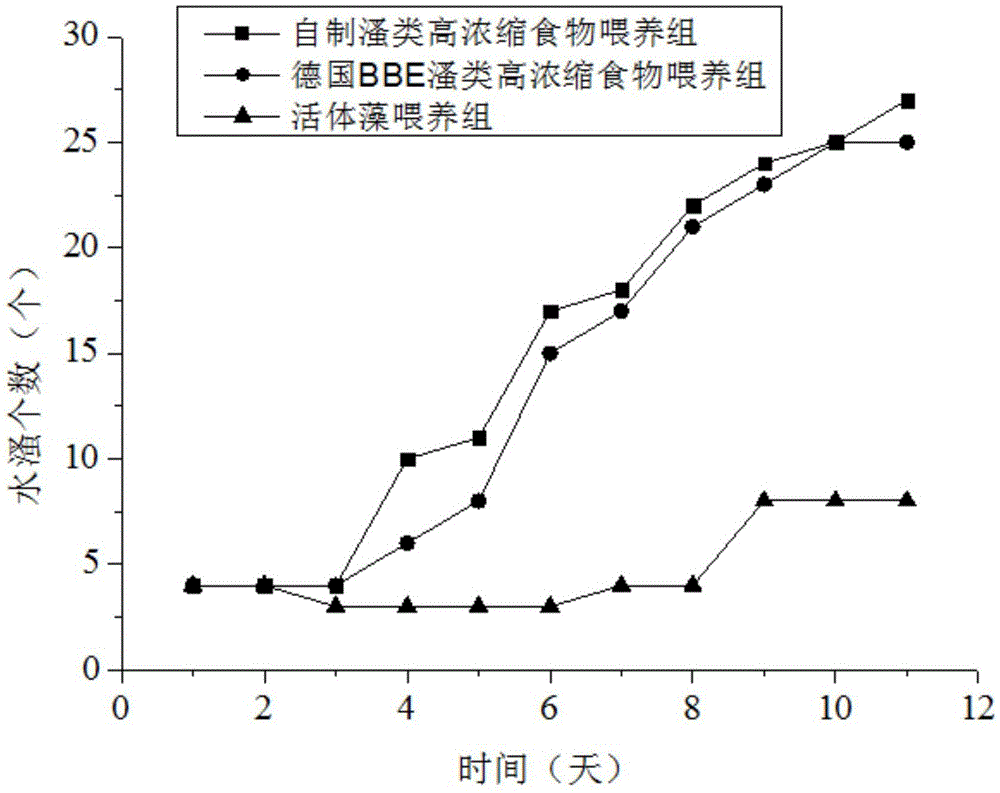

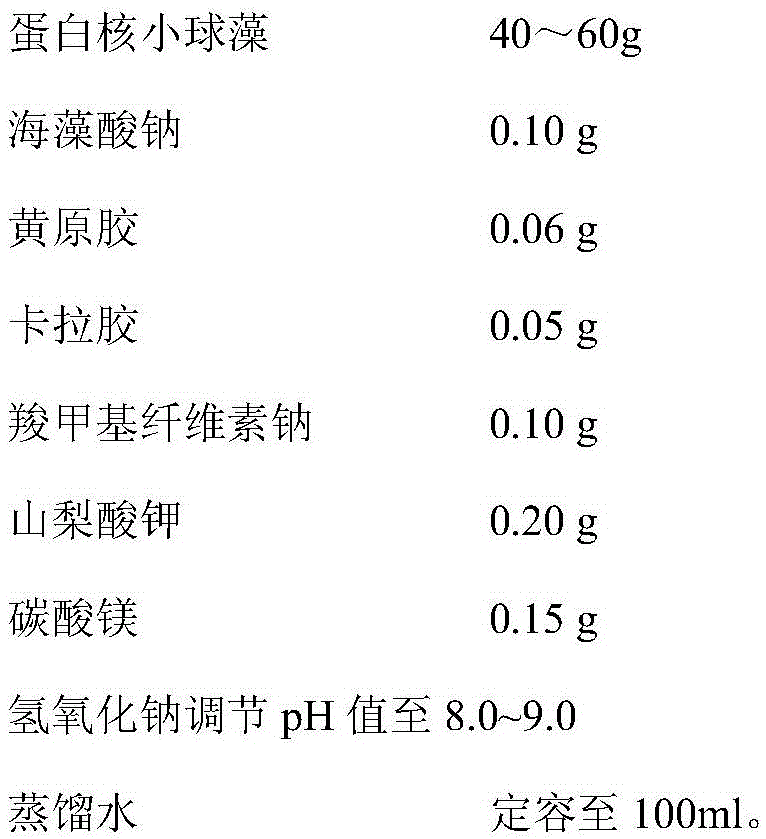

Alga-type highly-concentrated food and preparation method

ActiveCN104222027ASolve the problem of lack of oxygen at nightReduce the impactAnimal feeding stuffOxygen deprivationCarrageenan

The invention discloses alga-type highly-concentrated food and a preparation method. The alga-type highly-concentrated food is prepared by chlorella pyrenoidosa, sodium alginate, carrageenan, xanthan gum, sodium carboxymethylcellulose, potassium sorbate and magnesium carbonate in proportion. The preparation method solves the problem that in alga culture, oxygen deprivation is caused at night due to the fact that too many living algae are added, the influences caused by adding the living algae when the algae are used as biological indicators for conducting toxicity testing are reduced, and the precision of toxicity testing is improved. Due to the fact that the product is the highly-concentrated food, so that only a small number of algae need to be added during culture, the feeding frequency can be greatly reduced and the alga culture efficiency is improved.

Owner:武汉润江生态科技有限公司

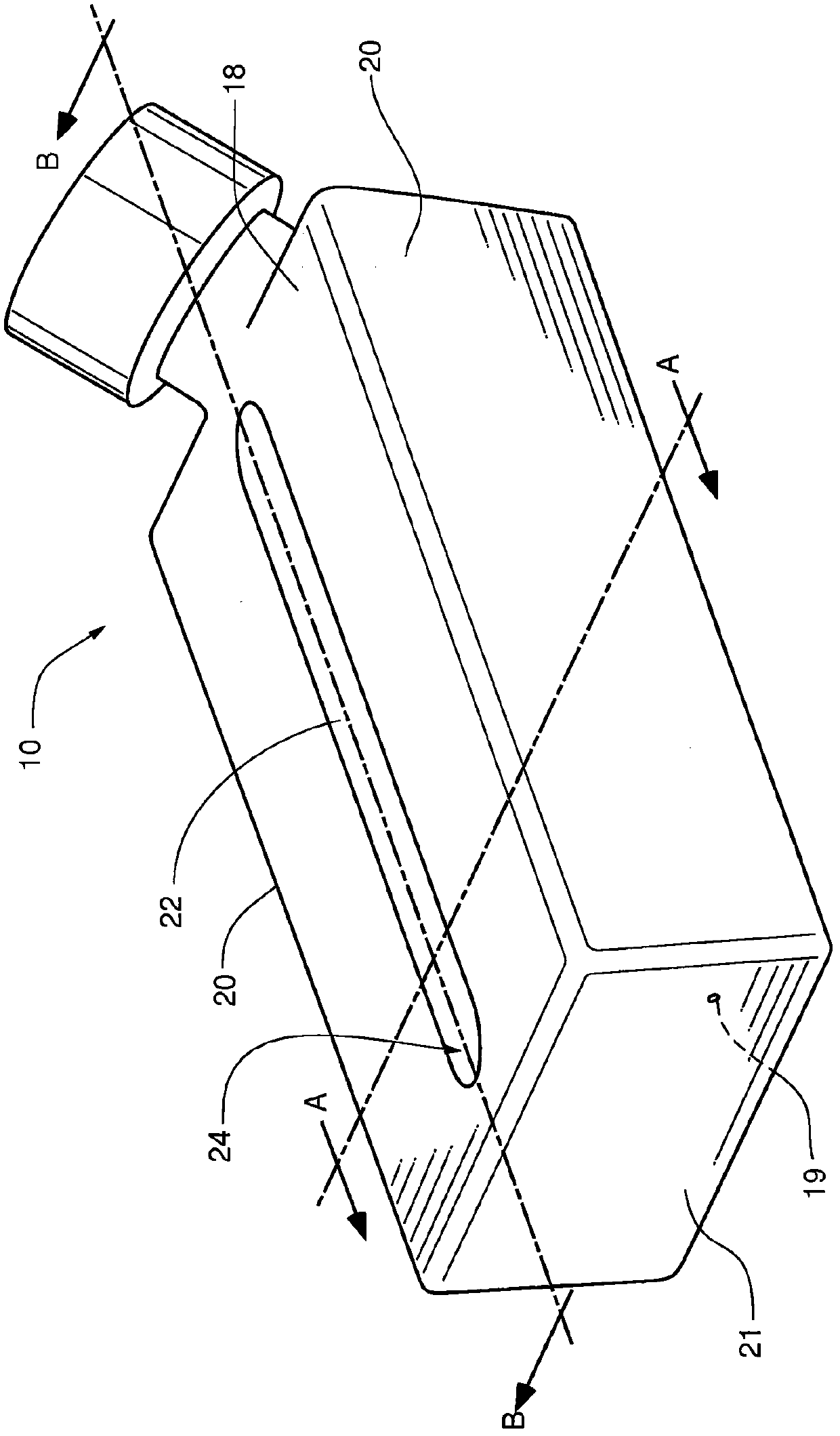

A kind of power battery dismantling equipment and method

ActiveCN103928727BSimple structureEasy to replaceWaste accumulators reclaimingBattery recyclingPower batteryEngineering

The invention relates to equipment for dismantling a power battery. The equipment is characterized by comprising a storage conveyer, an adjusting conveyer, an image system, an automatic adjusting and feeding mechanism, a cutting and feeding mechanism, an automatic cutting mechanism, an automatic separation mechanism and a discharge conveyer, wherein the storage conveyer, the adjusting conveyer, the automatic adjusting and feeding mechanism and the cutting and feeding mechanism are sequentially connected with one another; a camera is arranged above a feeding hole of the automatic adjusting and feeding mechanism; the automatic cutting mechanism is connected with a discharge hole of the cutting and feeding mechanism; the automatic separating mechanism is connected with another discharge hole of the cutting and feeding mechanism; the discharge conveyer is connected with the automatic separation mechanism. The invention also relates to a method for dismantling a power battery. The equipment has the advantages of being simple in structure, convenient to operate, high in automatic degree and high in dismantling efficiency, and belongs to the field of recovery treatment of a vehicle power battery.

Owner:GUANGDONG BRUNP RECYCLING TECH CO LTD +1

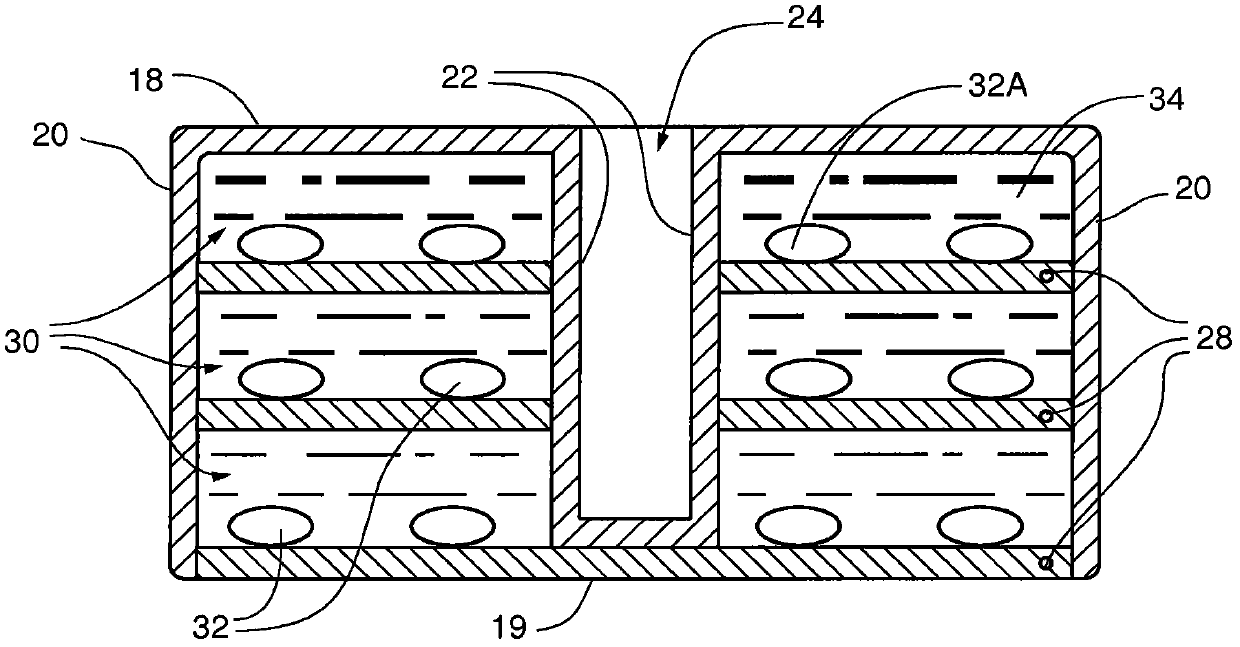

Improved gas permeable cell culture device and method of use

ActiveCN102089420AEffective trainingAbility to eliminate needBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryCell culture

Owner:WILSON WOLF MFG

High water-resistant aquatic organism anti-stress attractant additive and preparation method thereof

InactiveCN108991292AIncrease attractivenessImprove immunityFood processingClimate change adaptationAnti stressBetaine

The invention relates to a high water-resistant aquatic organism anti-stress attractant additive. The high water-resistant aquatic organism anti-stress attractant additive mainly comprises betaine, acomposite extract composed of an anti-stress natural component-pollen component co-extract, a polypeptide chelate calcium and peptide chelate ferrous complex chelate, Vc, citric acid, active polysaccharide, Taurine, complex free amino acid and trimethylpropyl glycine, and the above components are gelated to obtain a gel state anti-stress attractant additive product. The additive of the invention is prepared by aiming at stress environment of aquatic organism and the water environment, and can significantly improve the water resistance of the product and the anti-stress ability of the aquatic organism.

Owner:山东祥维斯生物科技股份有限公司

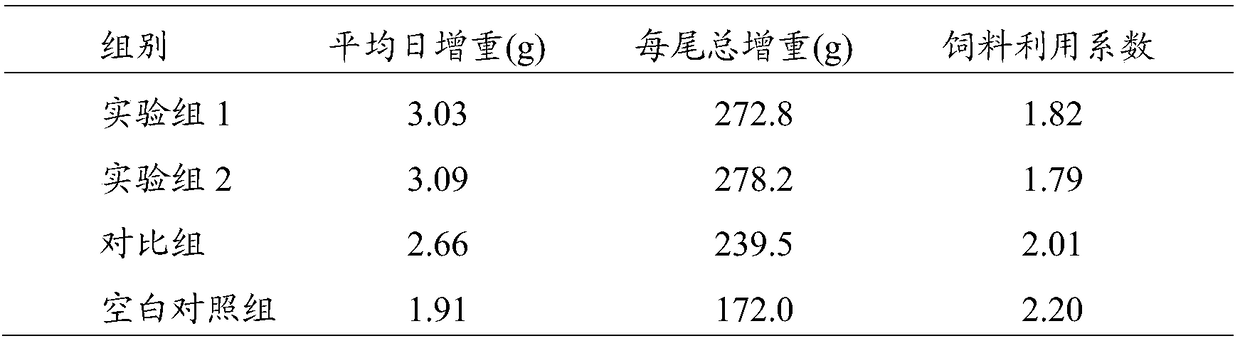

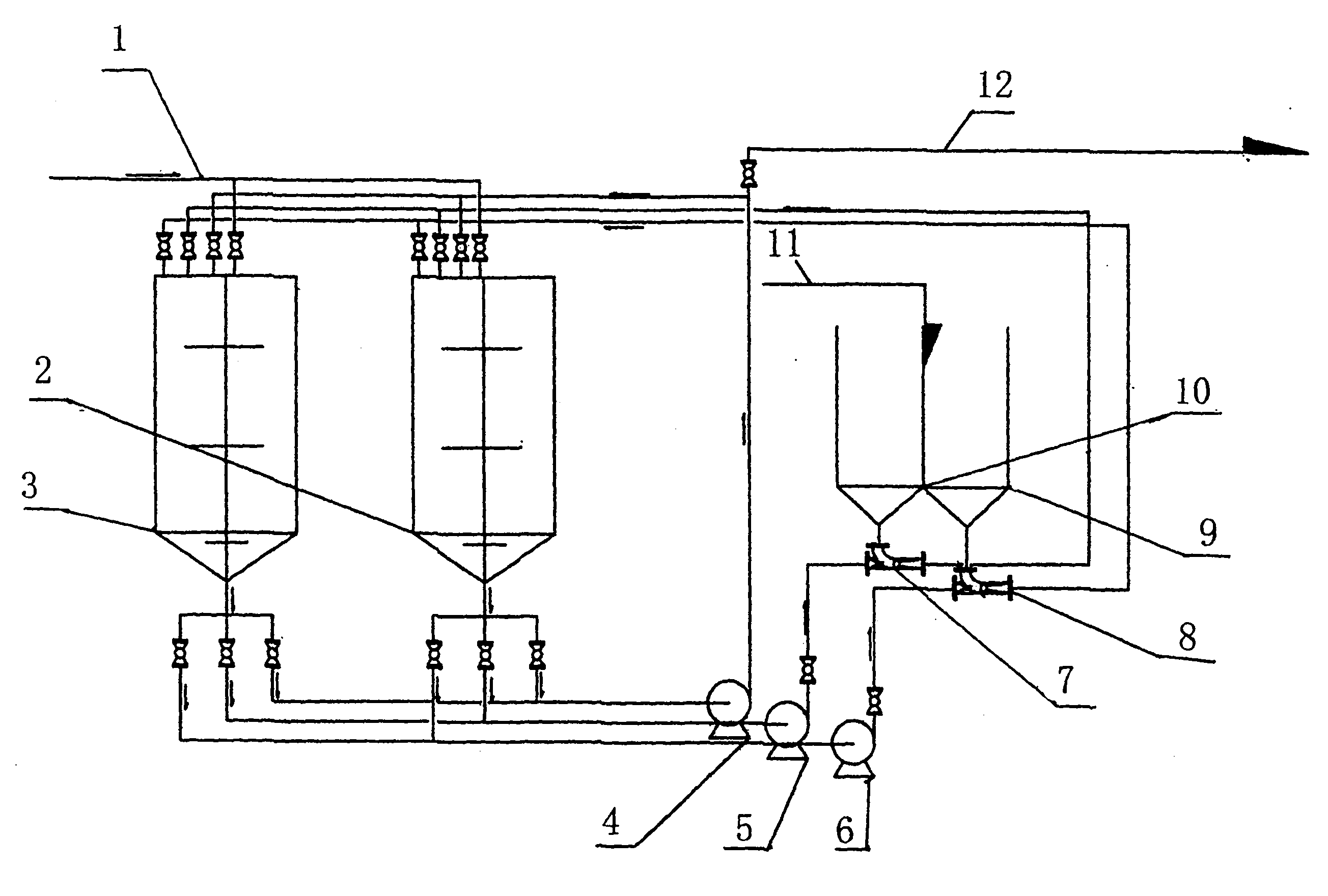

Feeding and conveying device of dry starch

The invention discloses a feeding and conveying device of dry starch. The feeding and conveying device is characterized in that an ion-free water input pipe is respectively connected with a first mixing tank and a second mixing tank, wherein the bottom ends of the first mixing tank and the second mixing tank are respectively connected with a discharge pump, a first spraying pump and a second spraying pump through pipelines; the upper ends of a first feeding tank and a second feeding tank are connected with a dry starch feeding pipe; the bottom ends of the first feeding tank and the second feeding tank are connected with upper inlets of a first dray starch sprayer and a second dry starch sprayer through pipelines; and outlets of the first dry starch sprayer and the second dry starch sprayer are connected with the first mixing tank and the second mixing tank through pipelines. With the structure, the invention reduces the feeding frequency, saves labor force and simultaneously improves the feeding efficiency.

Owner:ZHUCHENG DONGXIAO BIOTECH

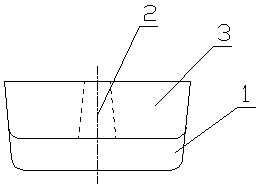

Hot dip coating zinc alloy in use for zinc plating narrow steel strip, method, and ingot mold of zinc alloy

InactiveCN101092683ALower requirementImprove liquidityHot-dipping/immersion processesSurface finishZinc alloys

This invention relates to hot-galvanized zinc alloy, its hot-dip galvanization method and its ingot for producing narrow steel belts. The hot-galvanized zinc alloy comprises: Al 0.4-1.0 wt.%, Pb 0.003-0.1 wt.%, Zn and impurities as balance. The T-shaped ingot of the hot-galvanized zinc alloy is a trapezoid with two symmetric warped ears. The ears have lift-off holes. The hot-galvanized zinc alloy is directly smelted into a zinc bath. The hot-galvanized zinc alloy can improve fluidity of zinc bath, decrease the residue rate, and increase the smoothness of the galvanization layer. The hot-galvanized zinc alloy is also used for preparing zinc-freepatterned plate.

Owner:ZHUZHOU SMELTER GRP

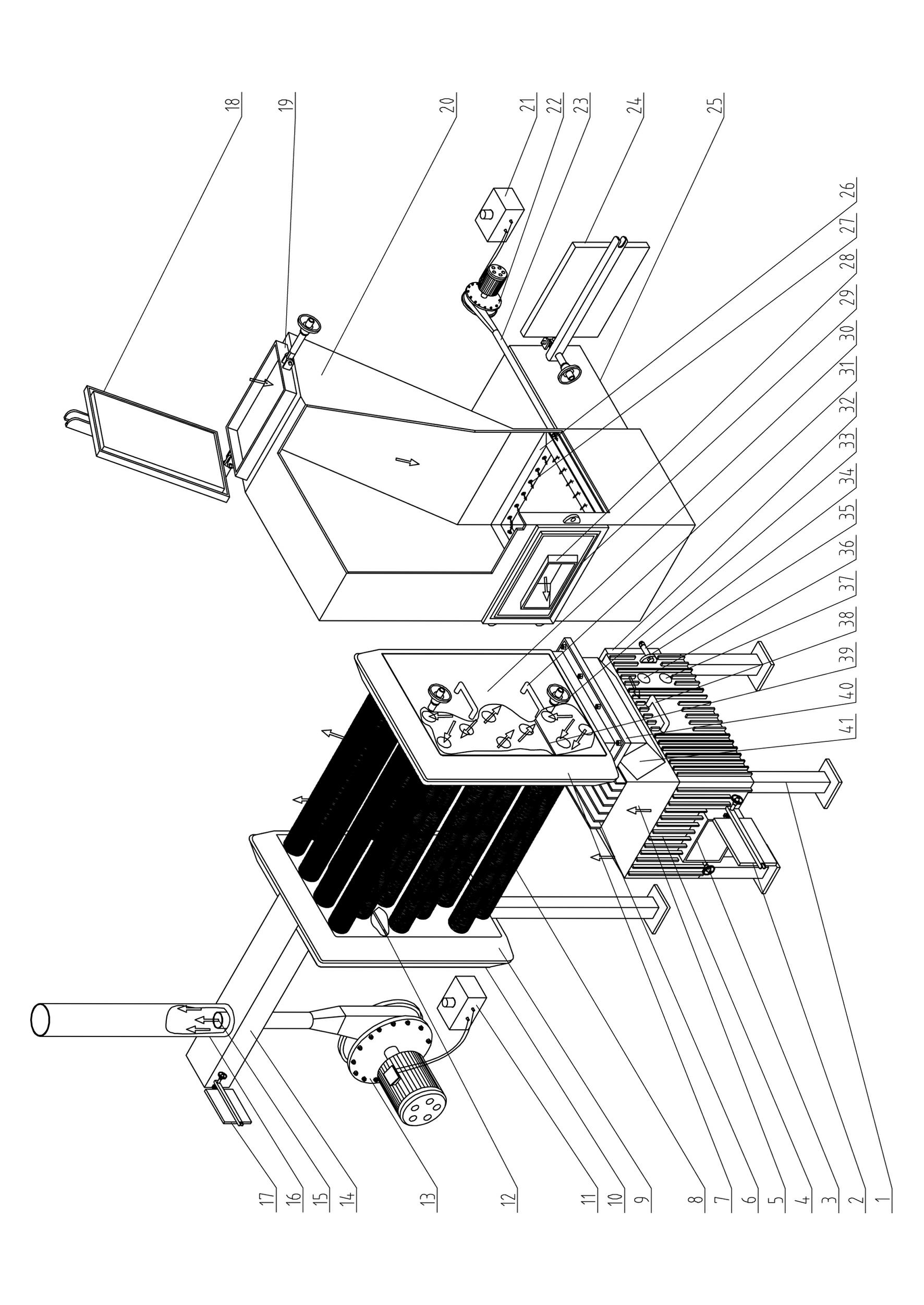

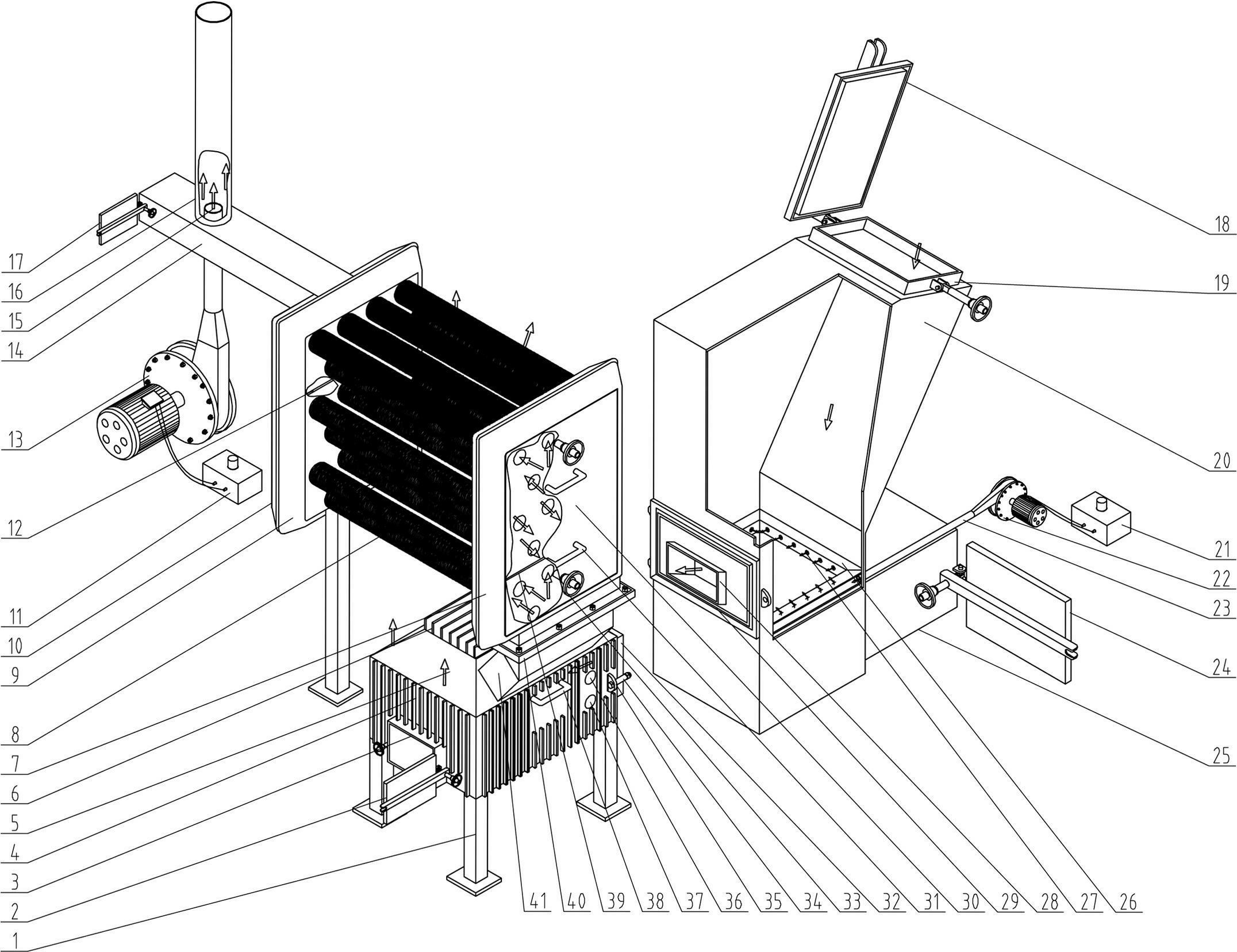

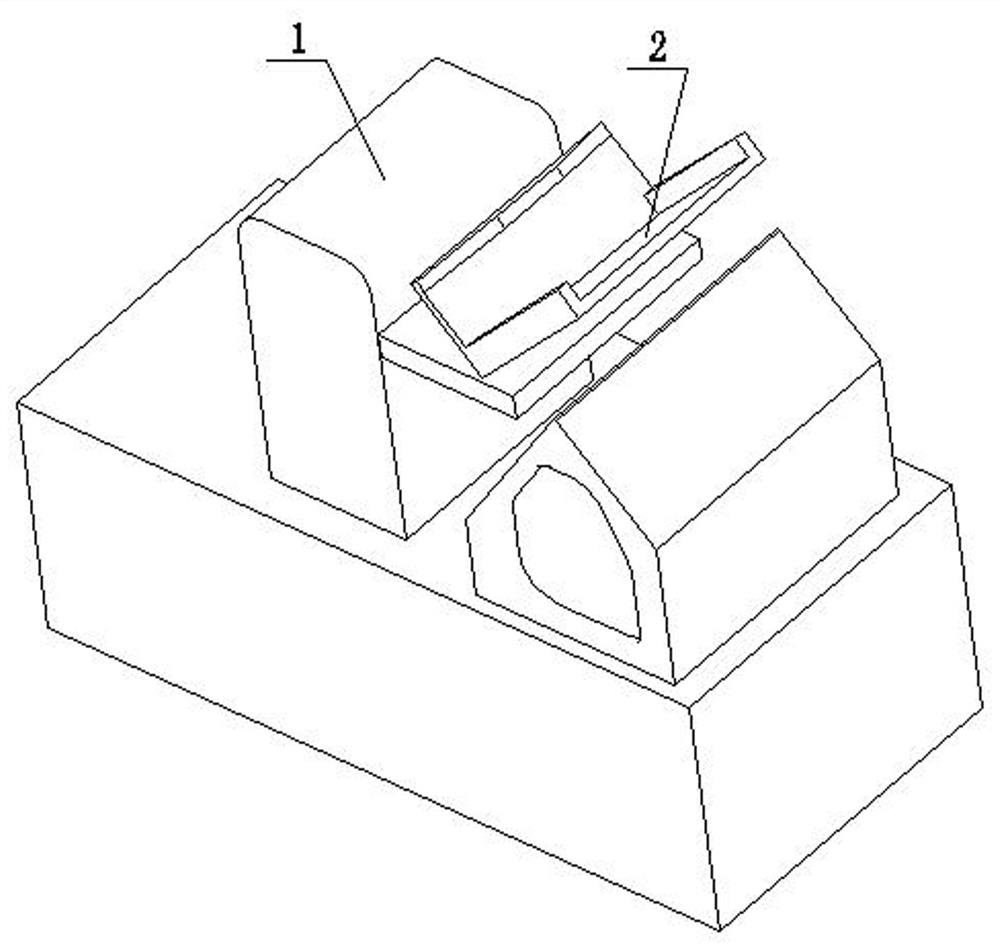

Combined combustion energy conversion flue-cured tobacco furnace

A combined combustion energy conversion flue-cured tobacco furnace comprises a heat reaction furnace, a heat exchange mechanism and a smoke exhaust mechanism. An annular air supply duct is arranged at the middle lower portion of a vaporizing chamber circumferentially and horizontally. Air supply holes are evenly arranged around the air supply duct which is connected with a draught fan through an air supply pipe penetrating through the wall of the vaporizing chamber. A heat energy nozzle is arranged on the lateral wall of the vaporizing chamber, one end of the heat energy nozzle extending out of the vaporizing chamber is connected with a sealed combustion chamber which is communicated with the vaporizing chamber through the heat energy nozzle, and an air inlet is arranged on the lateral wall of the combustion chamber. A left direction adjustment chamber is communicated with a right direction adjustment chamber through a radiation pipe, and the upper portion of the right direction adjustment chamber is drained through a smoke collecting pipe and a smoke exhaust pipe. The combined combustion energy conversion flue-cured tobacco furnace is high in heat efficiency and adapts to vaporization of high-quality coal and vaporization of wood coal and biomass briquettes. The solid fuel has a wide application range, and discharged ash serves as optimal raw materials of biomass fertilizers.

Owner:刘善华

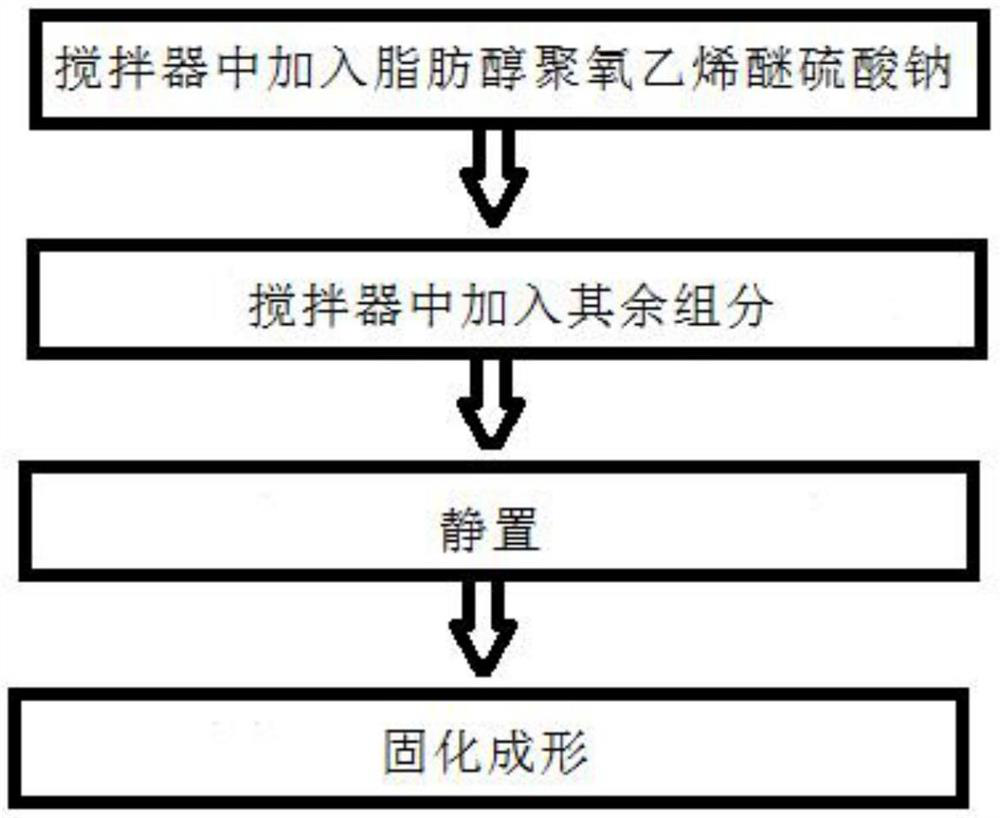

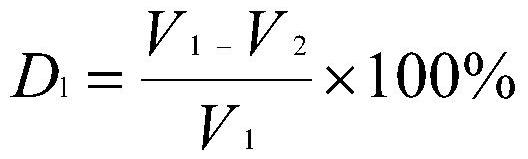

A slow-release liquid-carrying sand-carrying foam discharge agent and its preparation method

The invention belongs to the technical field of drainage of natural gas wells, and in particular relates to a slow-release liquid-carrying sand-carrying foam drainage agent and a preparation method thereof. The present invention uses fatty alcohol polyoxyethylene ether sodium sulfate, cocamidopropyl betaine, fatty alcohol polyoxyethylene ether, octadecyl dihydroxyethyl betaine, cetyltrimethylammonium bromide, poly Vinyl alcohol and sausage casing are prepared in four steps of adding fatty alcohol polyoxyethylene ether sodium sulfate into the mixer, adding other components into the mixer, standing and solidifying in a certain proportion. , has good salt tolerance, anti-mineralization degree, and has a slow release effect. The foaming agent dissolves slowly, can carry liquid and sand, and carry sand and water out of the wellbore at the same time, ensuring the normal production of the gas well.

Owner:PETROCHINA CO LTD

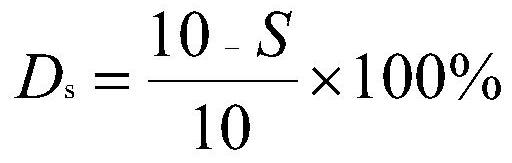

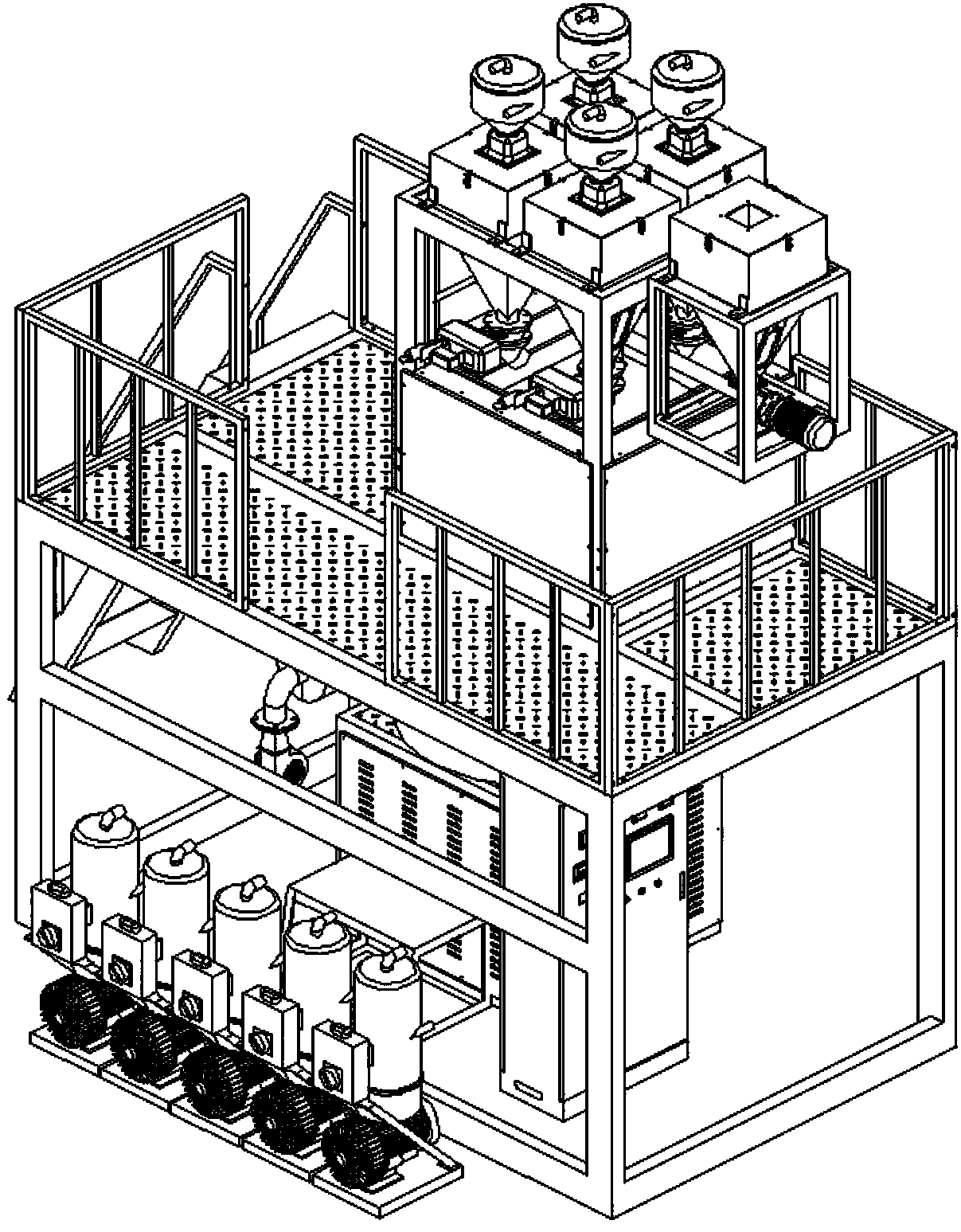

Production line device for one-time extrusion of TPO self-adhesion sand-surface waterproof coiled material

The invention discloses a production line device for one-time extrusion of a TPO self-adhesion sand-surface waterproof coiled material. The production line device comprises a material storage system,an automatic metering and batching system, a material mixing system, a material feeding system, an aggregating and glue filtering system, a main electric appliance control system, an aggregating mixing extruding machine, an automatic net changing system, a melt flow control system, an L-C main mold, a main three-roller setting machine, a non-woven fabric frame, an L-C auxiliary mold, an auxiliarythree-roller setting machine, an automatic constant-temperature vulcanization system, a glue and sand coating system, a full-automatic online thickness measuring system, an edge cutting device, an auxiliary traction machine, a storage frame and a main traction automatic cutting device, an automatic coiling machine and a weighing automatic packaging system. A product produced by the production line device has stable uniformity and super-high combined strength; and according to the production line device, the automation degree of the device is high, and the product performance and the production efficiency are obviously improved.

Owner:QINGDAO SHENDUN WATERPROOF TECH

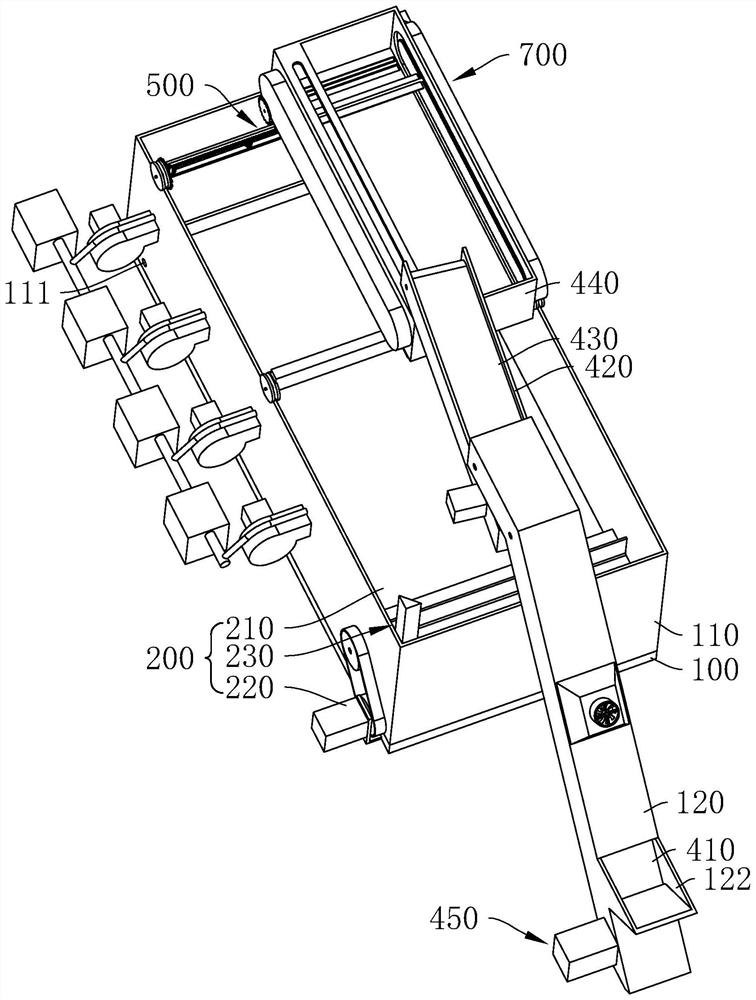

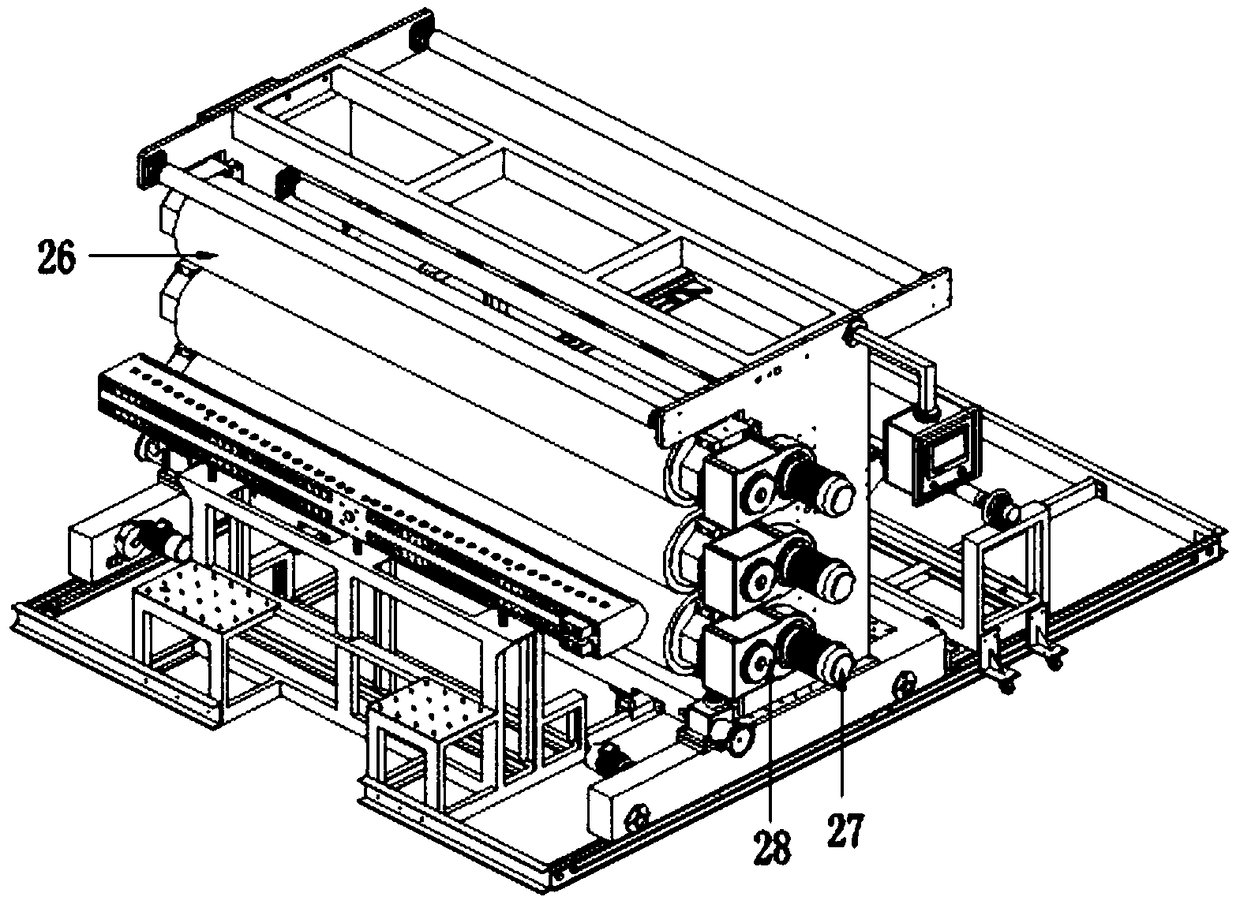

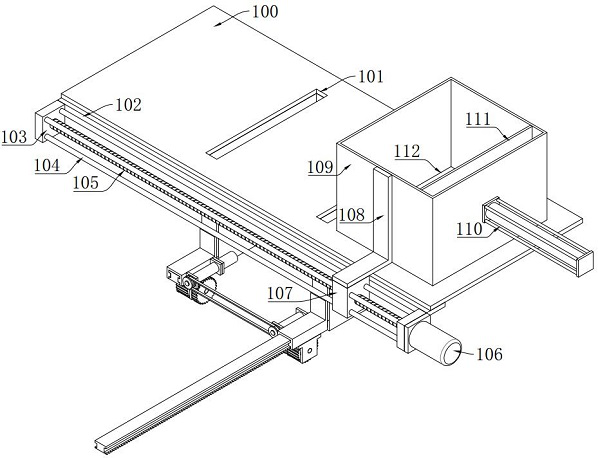

Drill point feeding device and equipment

ActiveCN112249663AIncrease the number ofGuaranteed to lay flatConveyorsConveyor partsDrive wheelElectric machinery

The invention provides a drill point feeding device and equipment. The drill point feeding device comprises a mounting bracket and a conveying mechanism. The conveying mechanism comprises a conveyingassembly, a rotating motor, a driving wheel, a driven wheel, a first connecting rod, a second connecting rod and a plurality of material pieces, wherein the conveying assembly is arranged on the driving wheel and the driven wheel in a sleeving manner, the plurality of material pieces are connected to the outer side of the conveying assembly, and each material piece is provided with a bearing face.The bearing surface of each material piece is used for bearing a material box filled with a drill point. The material pieces are arranged on the side edges of the conveying assembly. When the material boxes are placed on the bearing faces of the material pieces, the bottom faces of the material boxes abut against the bearing faces, the side faces of the material boxes are parallel to the conveying assembly, and the number of the material boxes placed on the conveying assembly is increased while it is guaranteed that the material boxes are horizontally placed, so that the number of the drill pints placed on the conveying assembly is increased, the drill point loading period of the drill points on the conveying assembly is prolonged, and the loading frequency of the drill points is reduced.

Owner:CAMELOT QINGYUAN HYTEC TECH INVESTMENT

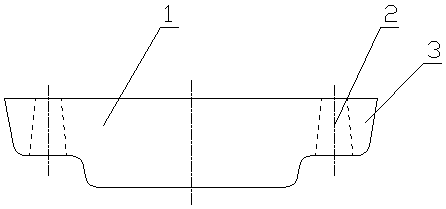

Hot dip galvanized alloy ingot for galvanizing narrow strip steel

InactiveCN109097630ALower requirementEasy to operateHot-dipping/immersion processesSurface finishSymmetrical ears

The invention provides a hot dip galvanized alloy ingot for galvanizing narrow strip steel. The hot dip galvanized alloy ingot comprises the components of, by weight, 1.2-1.4% of aluminum, 0.18-0.22%of antimony, 0.004% or the less of iron, 0.004% or the less of lead, 0.002% or the less of copper, 0.002% or the less of cadmium, and the balance zinc. According to the hot dip galvanized alloy for the narrow strip steel, fluidity of zinc bath can be obviously improved, the 'slag adhering' phenomenon of galvanized plates can be effectively reduced, the slag rate is reduced, and surface smoothnessof coatings is improved. The zinc alloy grade is RZ28, and the ingot weight is 1000 + / - 100kg, the ingot shape of the zinc alloy is of a 'T'-shaped cuboid with two symmetrical ear warps, the bottom ofthe cuboid is planar, lifting holes are formed in the ear warps, and the four sides are inclined planes, so that the cuboid is in a big-end-up shape.

Owner:ZHUZHOU SMELTER GRP

A carton paper automatic feeding device for a hard strip packaging machine

ActiveCN110239761BImplement the automatic addition functionFlexible usePackaging cigaretteConveyor beltIndustrial engineering

The invention discloses an automatic carton paper feeding device for a rigid strip packing machine, which comprises a support frame base, a foot is provided at the bottom of the support frame base, an oblique support frame is integrally formed on the top of the support frame base, and an oblique support frame is formed on the top of the support frame base The top is rotatably connected to the upper roller, and the bottom of the inclined support frame is rotatably connected to the lower roller arranged side by side with the upper roller, and a transmission belt is arranged around the upper roller and the lower roller, and the conveyor belt is equidistantly provided for supporting The load-bearing plate of carton paper is equipped with a material receiving mechanism on the inclined support frame; through the mutual cooperation between the conveyor belt lifting mechanism and the material receiving mechanism, the automatic addition function of the carton paper warehouse is realized, and it can also be adjusted according to the size of the space. The capacity of the carton conveyor belt has been adaptively changed, making it more flexible to use, ensuring automatic and continuous production during the working process of the CT rigid carton packaging machine without frequent addition of carton paper, reducing the feeding frequency and liberating productivity , Improve production efficiency and improve the degree of production automation.

Owner:CHINA TOBACCO HENAN IND

Corner treatment device for paperboard packaging and processing

PendingCN112604787AFor subsequent recyclingEasy to processGrain treatmentsPress ramElectric machinePaperboard

The invention belongs to the technical field of paperboard processing devices, and discloses a corner treatment device for paperboard packaging and processing. The corner treatment device comprises a base, an extrusion bin is fixedly connected to the top of the base, a forming bin is fixedly connected to one side of the extrusion bin, a shearing bin is fixedly connected to the top of the extrusion bin, a feeding hopper is fixedly connected to the top of the shearing bin, a shearing roller is fixedly installed in the shearing bin, a motor is fixedly installed on one side of the shearing bin, one side of the motor is in transmission connection with the shearing roller, and telescopic supporting legs are fixedly connected to the bottom of the base. According to the corner treatment device, the motor drives the shearing roller to shear corner paperboards of different shapes, follow-up treatment is facilitated, a stepping motor drives a threaded rod to rotate, a threaded sleeve is made to move, an extrusion plate is pushed, the paperboards are compressed, follow-up recycling and processing of the corner paperboards are facilitated, and the resource utilization rate is increased.

Owner:泰州市神彩包装有限公司

Profile cutting method of laser cutting automatic production line

ActiveCN112372156APlay a blocking roleAvoid Stuck SituationsLaser beam welding apparatusLaser cuttingManufacturing line

The invention discloses a profile cutting method of a laser cutting automatic production line. The profile cutting method comprises the following steps that S1, an operator adjusts the parameters of the laser cutting automatic production line according to the shape and the diameter of a profile needing to be cut, and after the parameters are adjusted, the profile needing to be cut is added into afeeding frame; and S2, a reciprocating type sorting and discharging mechanism is installed on the feeding frame, and the profile needing to be cut in the feeding frame is discharged in order through the reciprocating type sorting and discharging mechanism. According to the profile cutting method, the reciprocating type sorting and discharging mechanism and a clamping correction mechanism are additionally arranged on a feeding mechanism in the laser cutting automatic production line, so that the feeding efficiency of the feeding mechanism is remarkably improved, the feeding frequency of the operator is greatly reduced, the working efficiency of the laser cutting automatic production line is improved, the situation that manual feeding needs to be carried out by the operator in the productionprocess is avoided, and the potential safety hazards in the production process are greatly reduced.

Owner:王永凤

A kind of daphnia highly concentrated food and its preparation method

ActiveCN104222027BSolve the problem of lack of oxygen at nightHigh precisionAnimal feeding stuffHigh concentrationIndicator organism

The invention discloses a high-concentration food of daphnia and a preparation method thereof, which comprises chlorella pyrenoidum, sodium alginate, carrageenan, xanthan gum, sodium carboxymethyl cellulose, potassium sorbate and magnesium carbonate in a certain proportion formulated. The invention solves the problem of lack of oxygen at night caused by adding too much living algae in the cultivation of daphnia, reduces the influence caused by adding living algae when the daphnia is used as an indicator organism for toxicity testing, and improves the accuracy of toxicity testing. Because the product is a highly concentrated food, only a small amount can be added when cultivating daphnia, which can greatly reduce the feeding frequency and improve the cultivation efficiency of daphnia.

Owner:武汉润江生态科技有限公司

An automatic loading and unloading device for perforating charge assembly

The invention discloses an automatic feeding and discharging device for perforating bullet assembling. An assembling transferring mechanism is used for assembling materials and storing the materials temporarily; a four-shaft industrial robot is arranged between a material supplying and storing mechanism and the assembling transferring mechanism, and used for carrying the materials between the material supplying and storing mechanism and the assembling transferring mechanism; a punching robot is arranged between the assembling transferring mechanism and a hydraulic machine, and used for carrying the materials between the assembling transferring mechanism and the hydraulic machine; and a wall is arranged between the punching robot and the hydraulic machine. The feeding and discharging devicereduces the frequency of manual feeding and discharging, and is high in efficiency, wide in movement range, simple in structure and easy to control.

Owner:SICHUAN PETROLEUM PERFORATING EQUIP

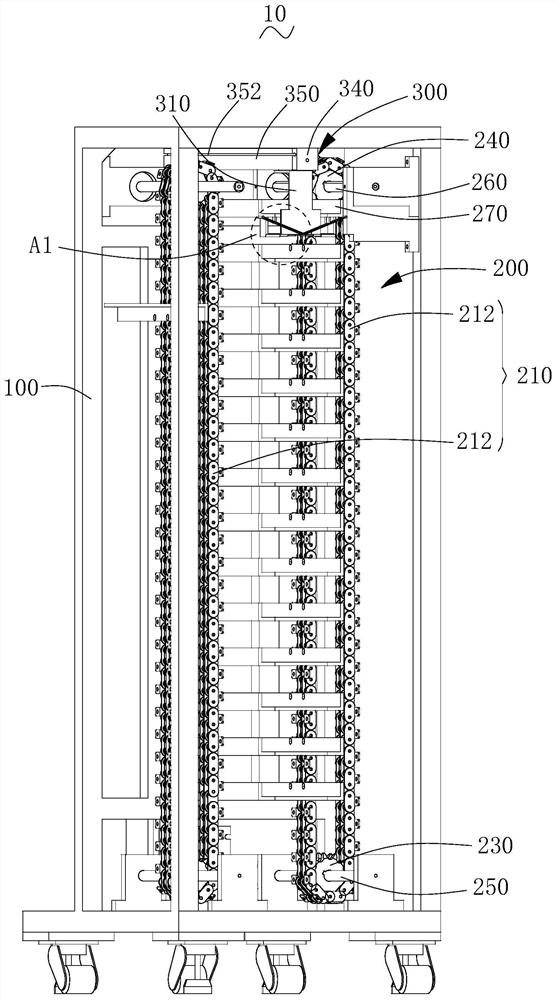

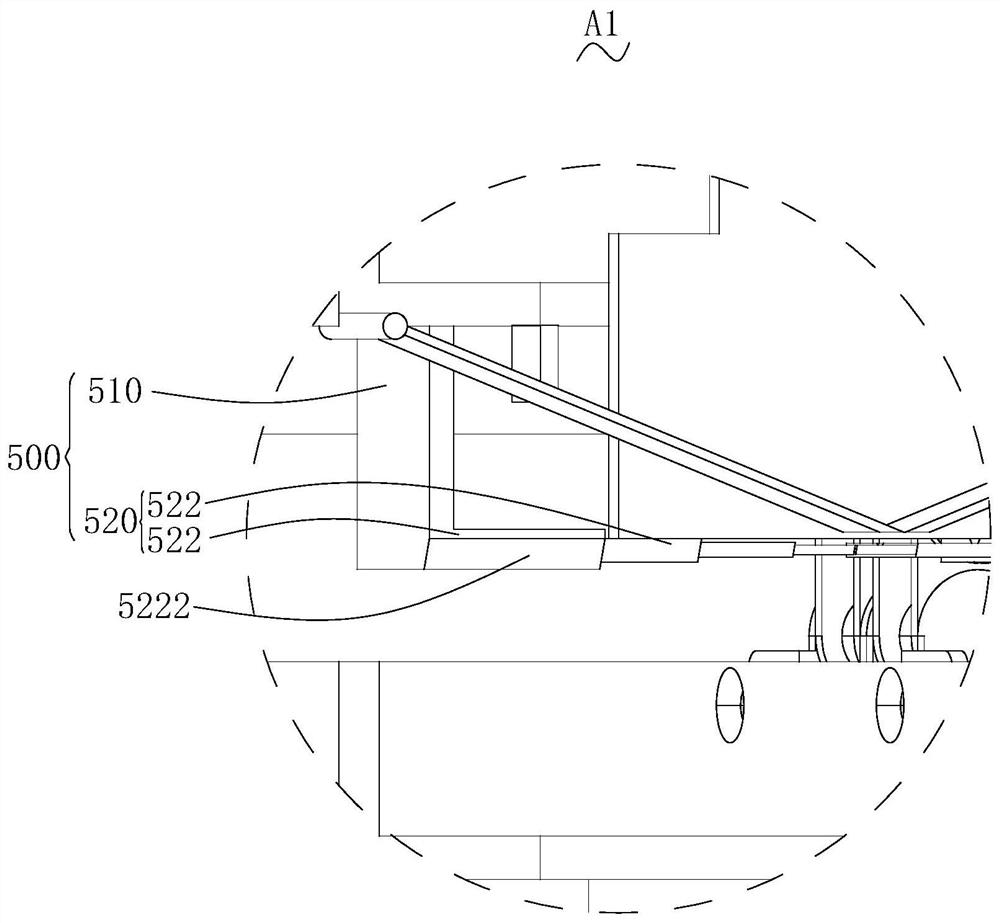

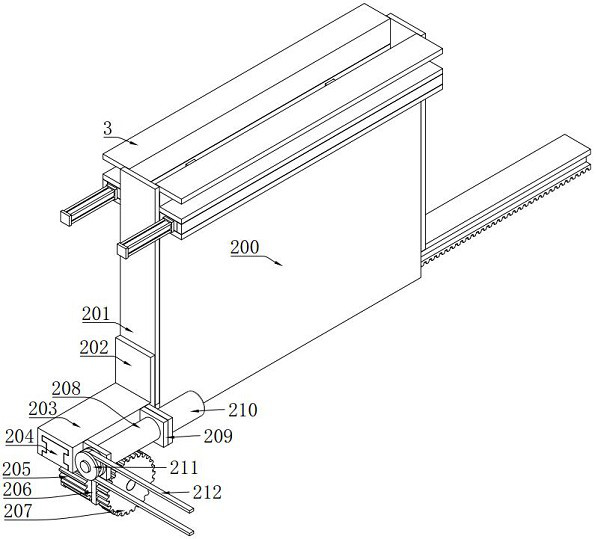

Automatic paging machine

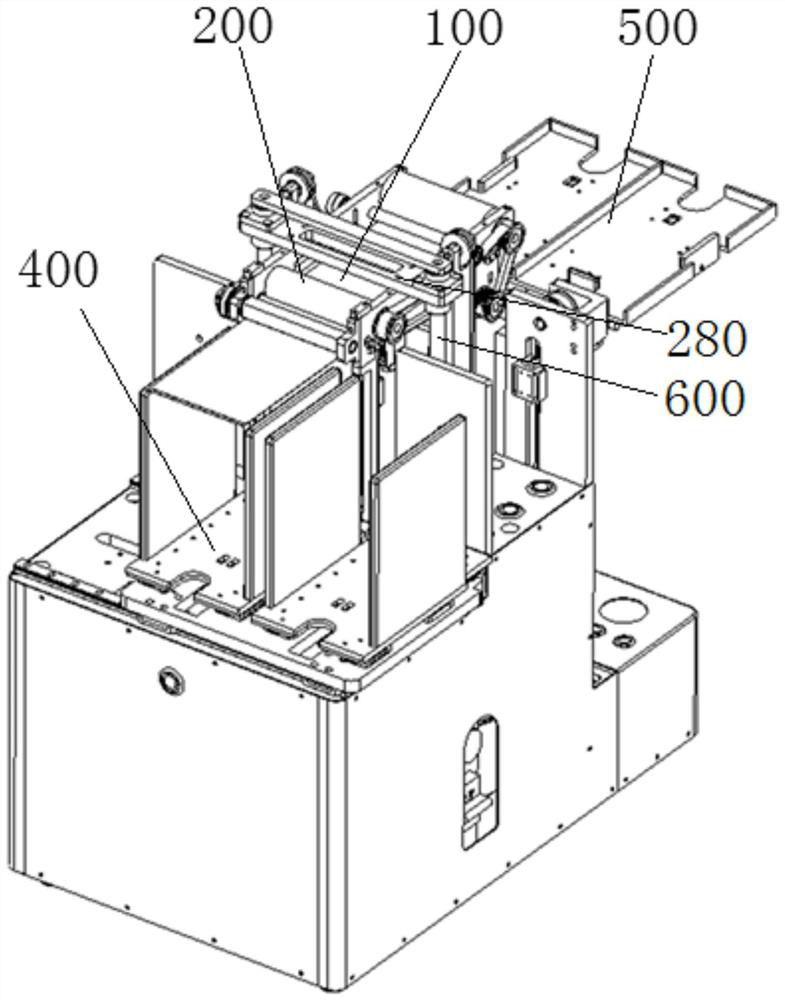

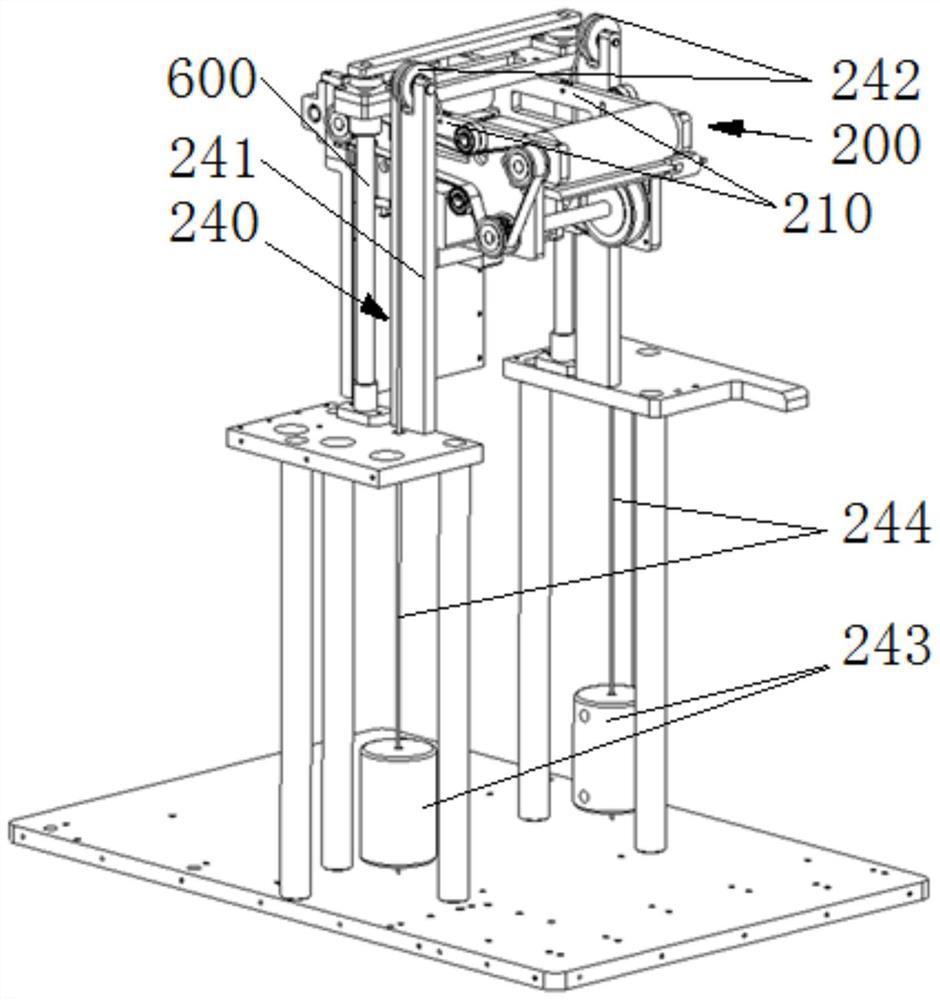

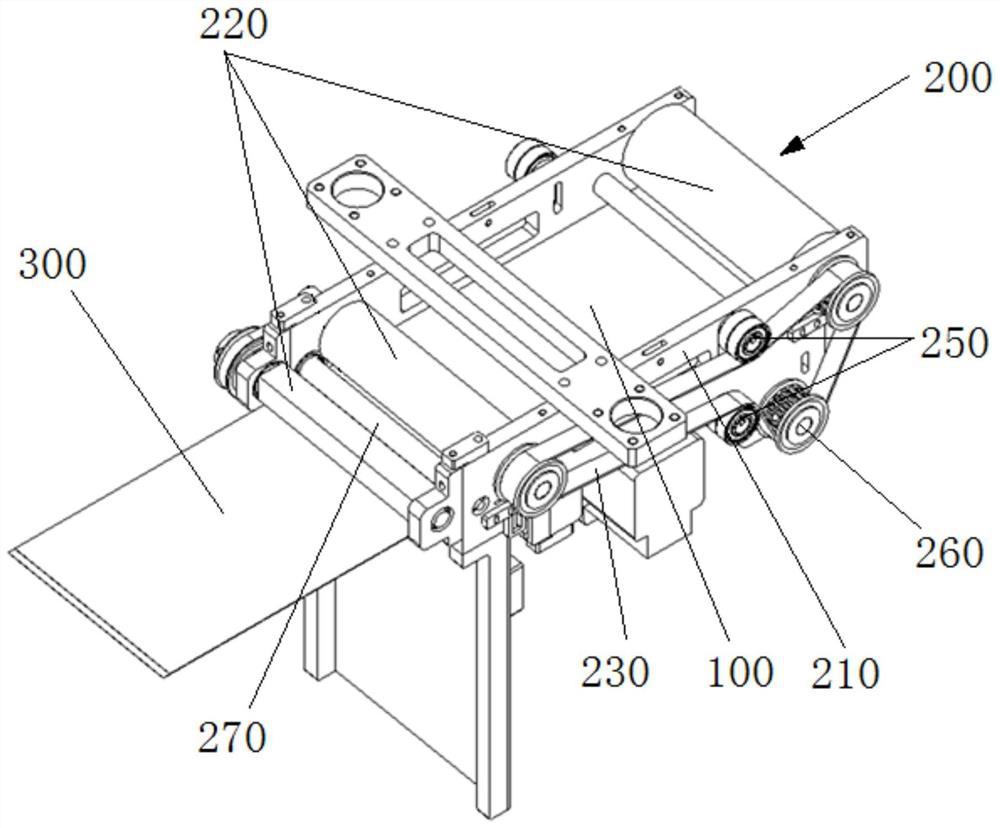

An automatic paging machine comprises a vertically-arranged guide shaft (600), a supporting table (100) directly or indirectly installed on the guide shaft (600) slidably and a paper rubbing module (200) arranged on the supporting table (100) in a supporting manner; the paper rubbing module (200) comprises two first supporting pieces (210), a plurality of rubber rolling shafts (220) arranged in parallel and a rolling supporting shaft (270); the rolling supporting shaft (270) is rotatably mounted on the two first supporting pieces (210) respectively; the automatic paging machine further comprises an air cylinder (610) used for driving the supporting table (100) to ascend and descend on the guide shaft (600) so that the rolling supporting shaft (270) can be supported on a paper stack formed by stacking paper (300); and the automatic paging machine further comprises an adjusting module (240) which is connected with the paper rubbing module (200) and used for applying upward acting force to the paper rubbing module (200) so as to adjust sliding friction force between the rubber rolling shafts (220) and the paper (300). The automatic paging machine is novel in design and high in practicability.

Owner:SHENZHEN KAIFA TECH

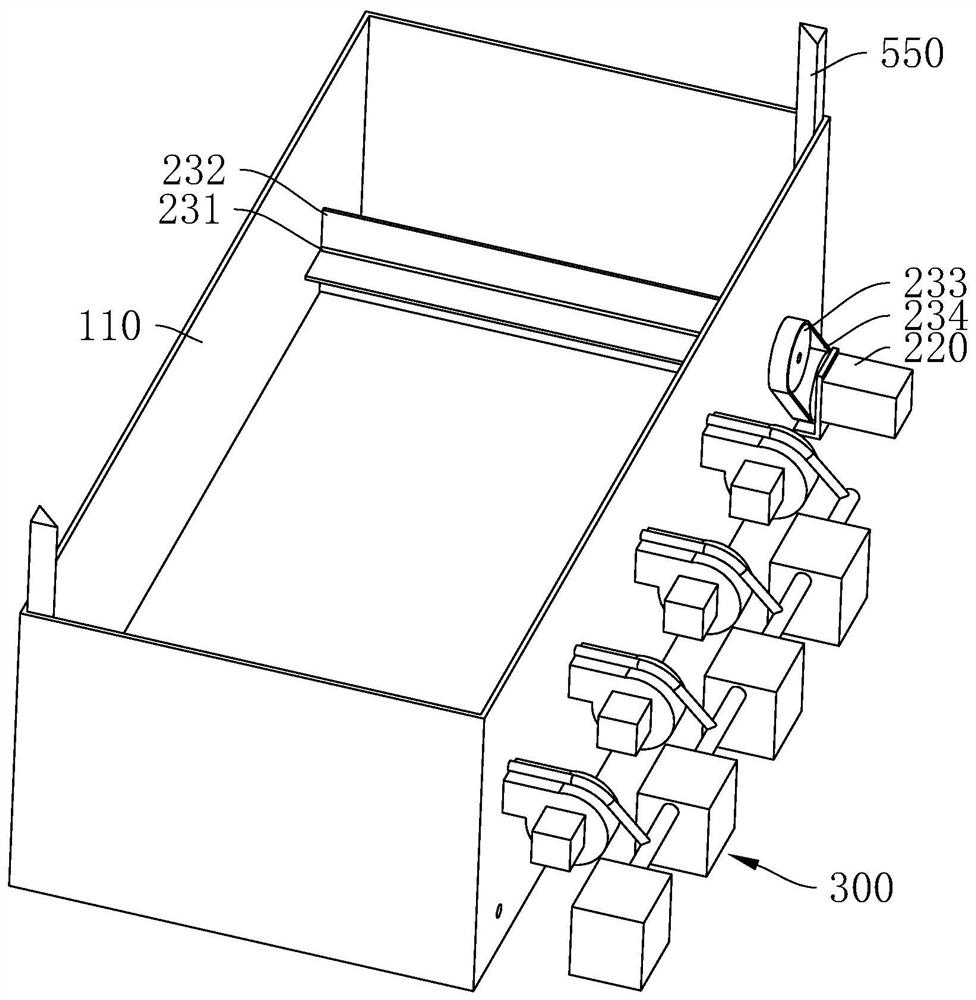

A device and method for automatic sorting and guiding bonding of regular fragments

InactiveCN109230288BLarge capacityEasy accessJigging conveyorsConveyor partsRound tableControl system

Owner:SICHUAN UNIV

Drill needle feeding device and equipment

ActiveCN112249663BIncrease the number ofGuaranteed to lay flatConveyorsConveyor partsDrive wheelElectric machinery

The present application provides a drilling needle feeding device and equipment. The above-mentioned drill needle feeding device includes a mounting bracket and a transmission mechanism; the transmission mechanism includes a transmission assembly, a rotating motor, a driving wheel, a driven wheel, a first connecting rod, a second connecting rod and a plurality of material pieces, and the transmission assembly is respectively sleeved on the driving On the pulley and the driven wheel, multiple material pieces are connected to the outside of the transmission assembly, each material piece has a bearing surface, and the bearing surface of each material piece is used to carry the material box with the drill. By setting the material parts on the side of the transmission component, when the material box is placed on the carrying surface of the material part, the bottom surface of the material box is in contact with the carrying surface, and the side of the material box is parallel to the transmission component, ensuring that the material box is placed flat At the same time, increasing the number of material boxes placed on the transmission assembly increases the number of drilling needles placed on the transmission assembly, prolongs the feeding cycle of the drilling needles on the transmission assembly, and reduces the feeding frequency of the drilling needles .

Owner:CAMELOT QINGYUAN HYTEC TECH INVESTMENT

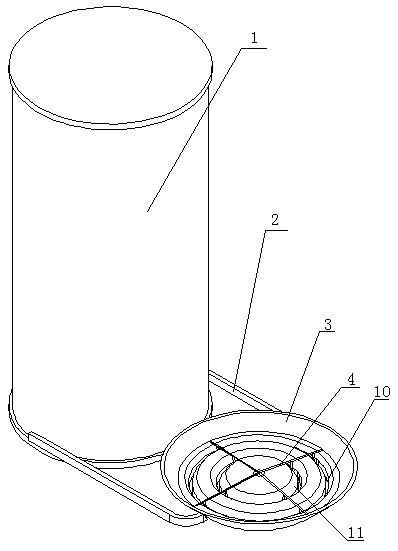

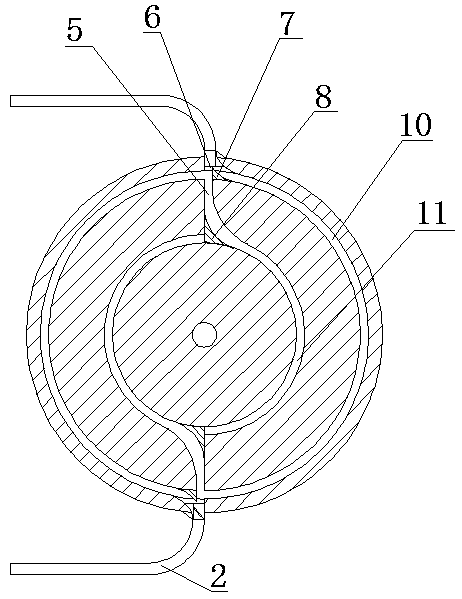

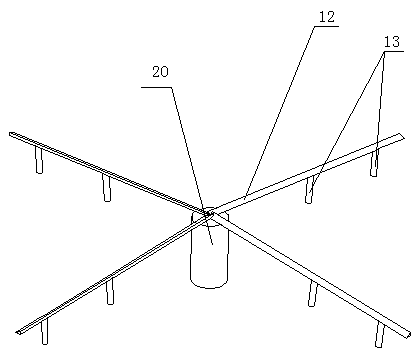

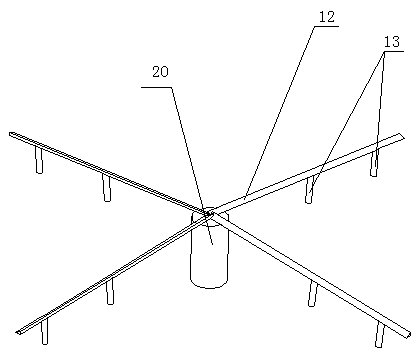

Regular fragment automatic sorting and guided bonding device and method

The invention discloses a regular fragment automatic sorting and guided bonding device and method. The device comprises a driving mixing device, a material sorting device, a guided bonding pipeline and an adjusting control system, wherein the adjusting control system is used for adjusting the rotation parameter of the driving mixing device, and the rotation and movement parameters of a housing, and controlling a coupling relationship between the parameters of the driving mixing device and the housing. The bottom of the material sorting device is provided with concentric inner and outer grooves. The middle of the bottom of the material sorting device is a round table on which the drive mixing device is disposed. The guided bonding pipeline is connected to the material sorting device. The regular fragment automatic sorting and guided bonding device realizes the integrated automatic arrangement and bonding of the fragment and the housing through the material sorting device, the driving mixing device and the elastic bonding module, realizes high-quality automatic unmanned production, firm bonding, low production cost, simple structure, no vibration and noise.

Owner:SICHUAN UNIV

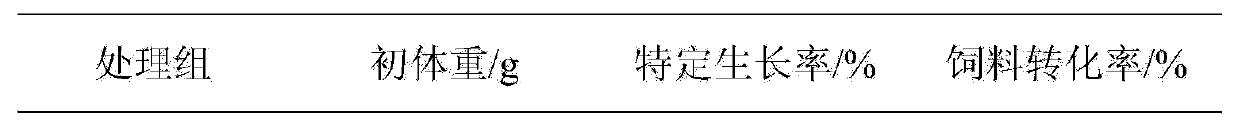

A kind of feed for juvenile semi-smooth tongue sole and its preparation method and feeding method

ActiveCN105595062BReduce usageReduce manufacturing costFood processingClimate change adaptationFeed conversion ratioGrape seed

The invention belongs to the technical field of aquaculture, in particular to feed for juvenile cynoglossus semilaevis, a method for preparing the feed for the juvenile cynoglossus semilaevis and a method for feeding the feed for the juvenile cynoglossus semilaevis. The feed for the juvenile cynoglossus semilaevis comprises, by weight, 28-36 parts of fish meal, 10-20 parts of bean pulp, 10-20 parts of Antarctic krill meal, 9-18 parts of undaria pinnatifida, 9-15 parts of artemia powder, 6-12 parts of rapeseed meal, 5-10 parts of nereis powder, 6-10 parts of squid powder, 8-12 parts of paddy rice husk, 4-8 parts of enteromorpha powder, 4-6 parts of eichhornia crassipes, 3-6 parts of grape seeds, 2-4 parts of herba portulacae, 2-5 parts of herba houttuyniae, 2-4 parts of almond powder, 1-2 parts of periostracum cicadae, 3-5 parts of herba lophatheri and the like. The feed and the methods have the advantages that the feed is high in conversion rate, and the juvenile cynoglossus semilaevis prefers feeding the feed and is high in specific growth rate after being fed with the feed.

Owner:OCEAN UNIV OF CHINA

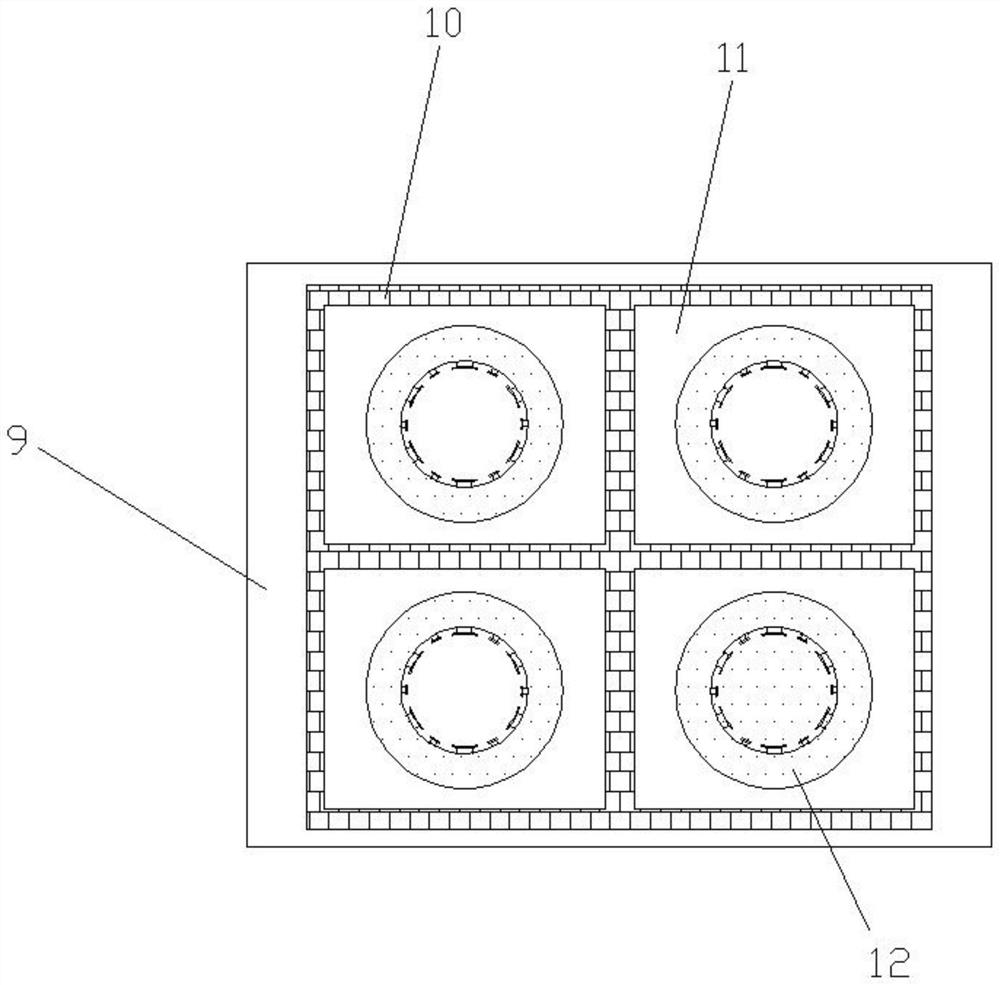

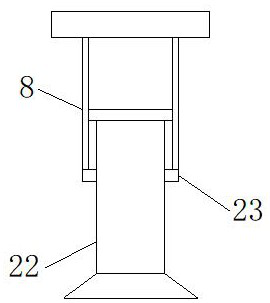

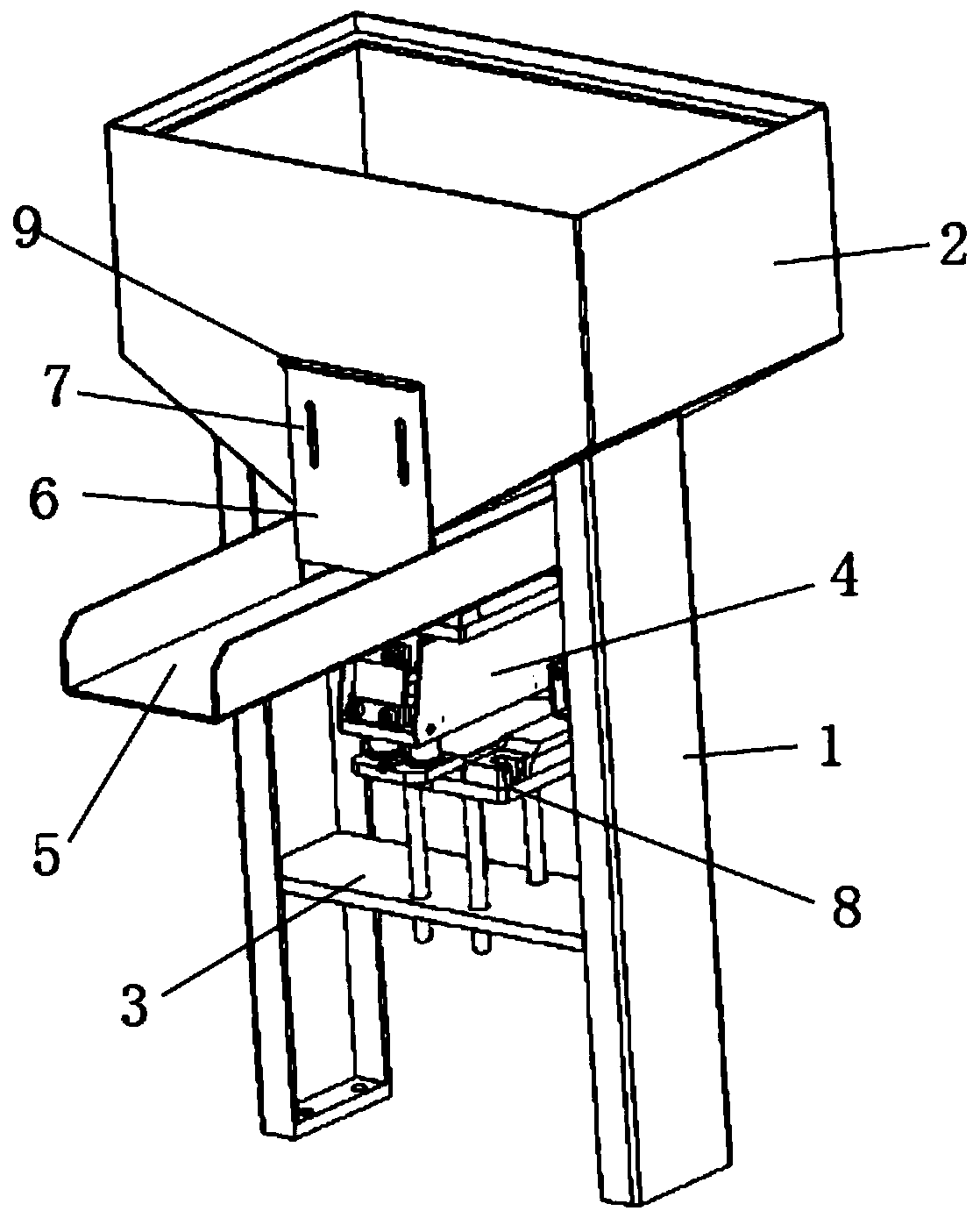

General assembly supply device

InactiveCN110950014ATimely supplyReduce feeding frequencyConveyorsLoading/unloadingGeneral assemblyEngineering

The invention discloses a general assembly supply device. The general assembly supply device comprises two stand columns, wherein the tops of the two stand columns are fixedly equipped with a storagefunnel; a mounting platform is further arranged between the two stand columns below the storage funnel; a vibrator is arranged on the mounting platform; a guide slot is formed in the top of the vibrator; a discharge hole in the bottom of the storage funnel is correspondingly formed in a groove of the guide slot; and an unloading baffle plate is further arranged on the storage funnel. The general assembly supply device can reduce supply frequency, and reduces labor amount.

Owner:常州市尚嘉宏织造有限公司

A material box alternate conveying device for ic detection

ActiveCN114426196BReduce the frequency of placingReduce work intensityDe-stacking articlesConveyor partsEngineeringMechanical engineering

The invention relates to an alternate conveying device for material boxes for IC detection, which belongs to the technical field related to IC detection, and includes a feeding mechanism, a feeding mechanism, a lower stop mechanism and a feeding mechanism; the number of feeding mechanisms is two, and they are all arranged in The lower end of the material mechanism, the quantity of the lower stop mechanism is four, and every two lower stop mechanisms are all arranged on the upper end of a blanking mechanism, and the feeding mechanism is located at the discharge end of the lower end of the blanking mechanism. The present invention facilitates the alternate automatic feeding operation filled with IC material boxes when performing IC detection through the feeding mechanism, unloading mechanism, lower stop mechanism and loading mechanism, and can store multiple rows of material boxes at a time. Therefore, the frequency of placing the material box is reduced, and the work intensity of the operator is reduced. At the same time, the efficiency of material feeding is significantly improved through the alternate feeding method.

Owner:四川明泰微电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com