Scenting machine

A flower scenting machine and frame technology, applied in the field of scenting machines, can solve the problems of increasing the work intensity of operators, reducing the production efficiency of scented tea, and reducing the work efficiency of operators, so as to reduce adverse effects, reduce accumulation and agglomeration, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

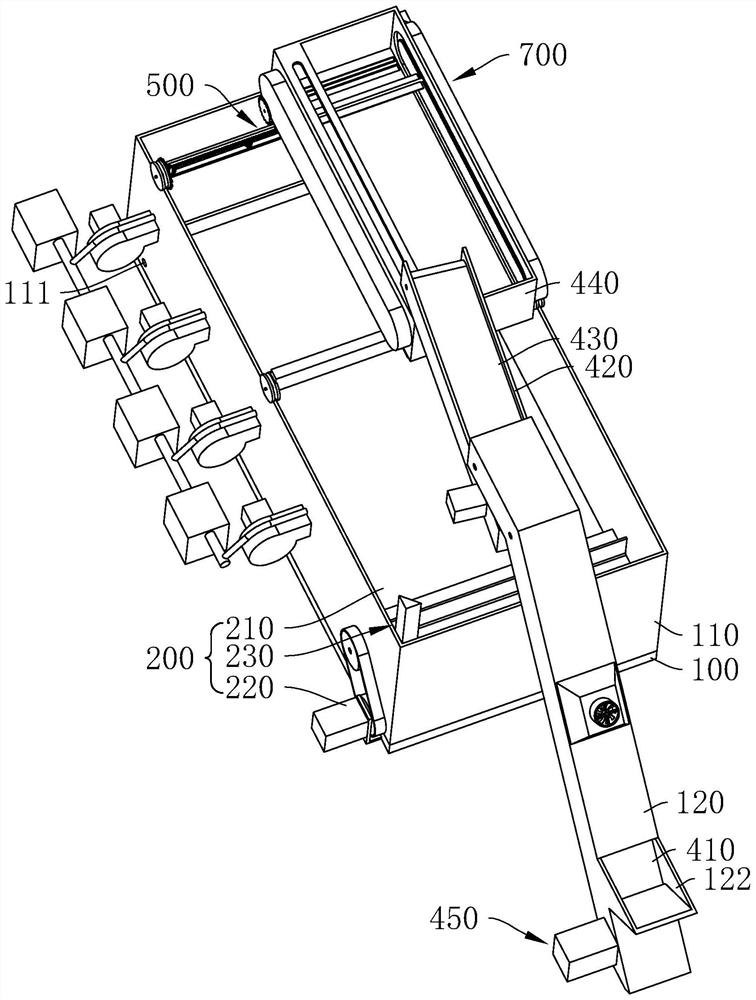

[0044] The following is attached Figure 1-9 The application is described in further detail.

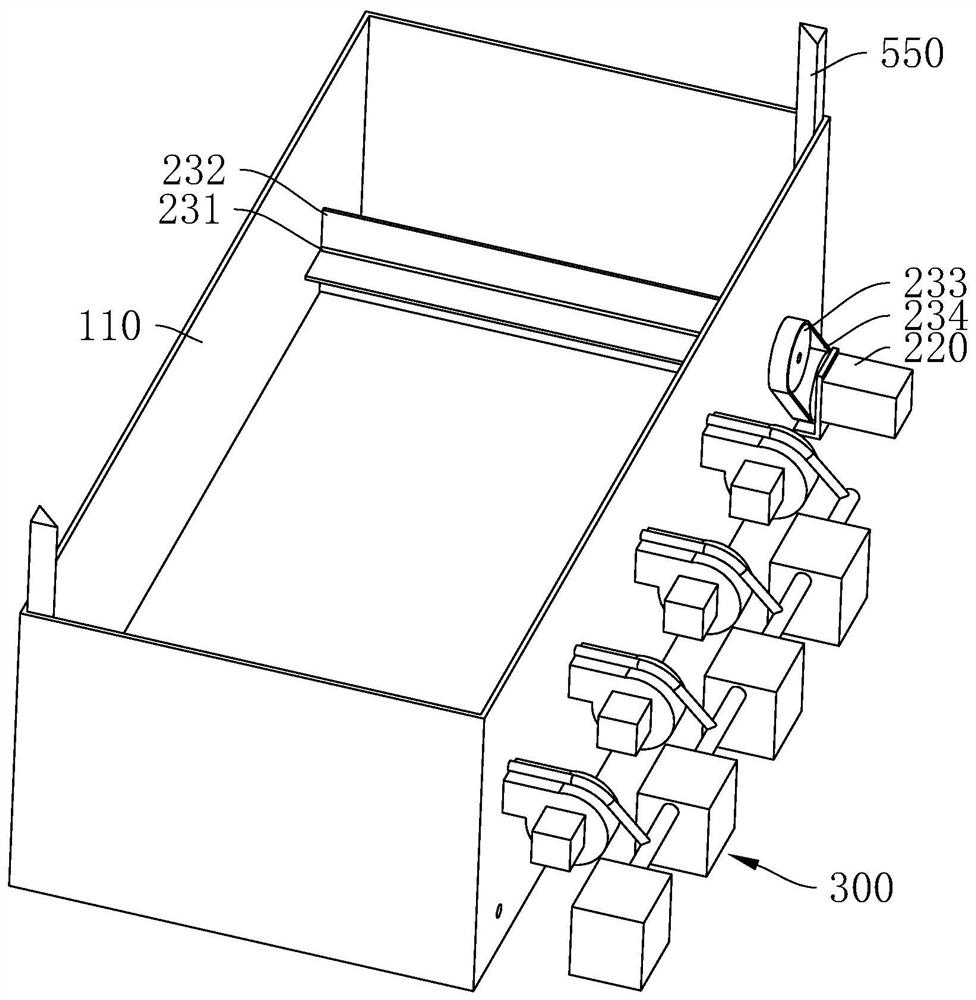

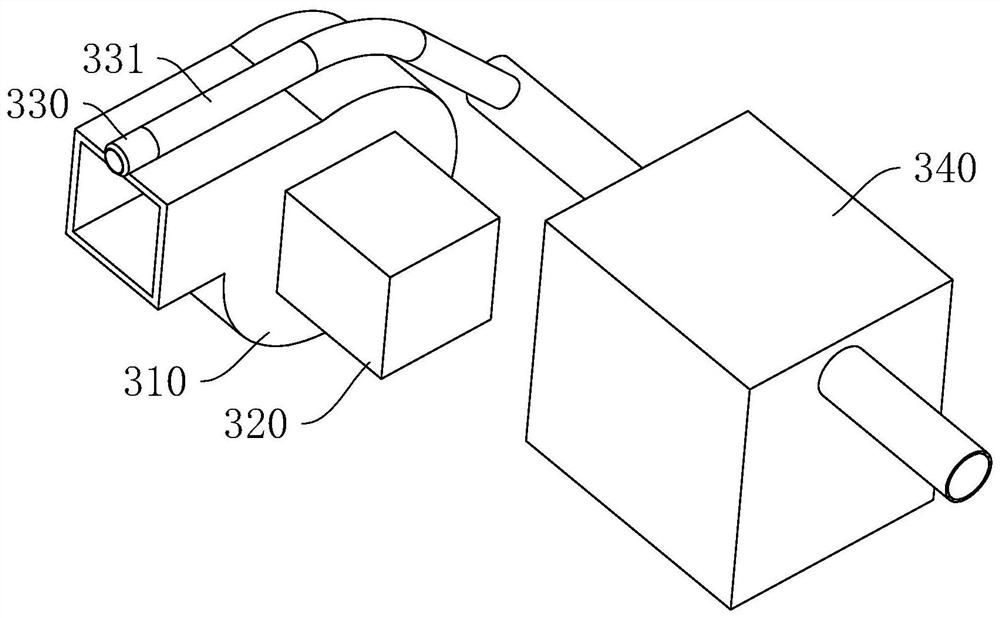

[0045] refer to figure 1 , a flower scenting machine, comprising a frame 100, on which a strip-shaped storage box 110 is horizontally fixed, and both ends of the storage box 110 are horizontally rotated to be provided with a third rotating shaft 111, the third rotating shaft 111 The length direction is perpendicular to the length direction of the storage box 110; the storage box 110 is provided with a feed assembly 200, and the feed assembly 200 includes a third conveyor belt 210, a transmission motor 220 and a leveler 230, and the third conveyor belt 210 is sleeved between two On the third rotating shaft 111, the third conveyor belt 210 rotates synchronously with the third rotating shaft 111, the transmission motor 220 is fixedly connected to the outer wall of the storage box 110 horizontally, and the output shaft of the transmission motor 220 is coaxially fixedly connected to one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com