Material box alternate conveying device for IC detection

A technology for conveying devices and materials, which is applied in the directions of transportation and packaging, conveyor objects, and object destacking. frequency, reduce the frequency of feeding, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

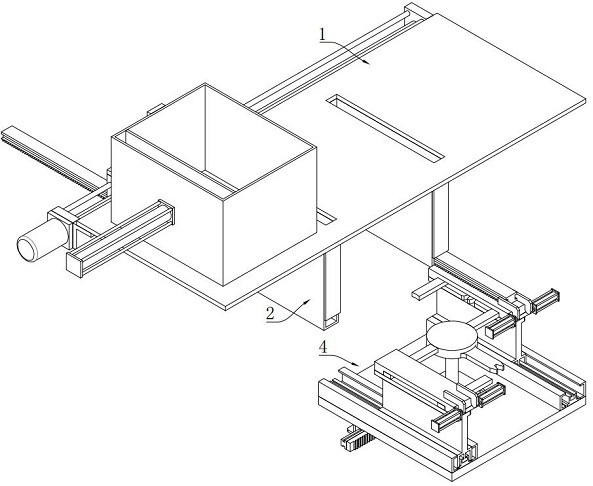

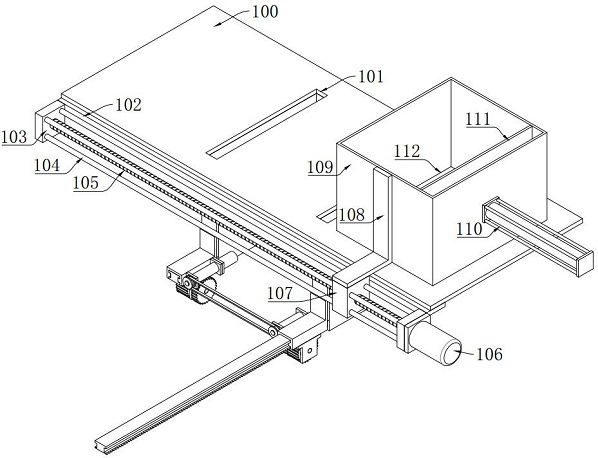

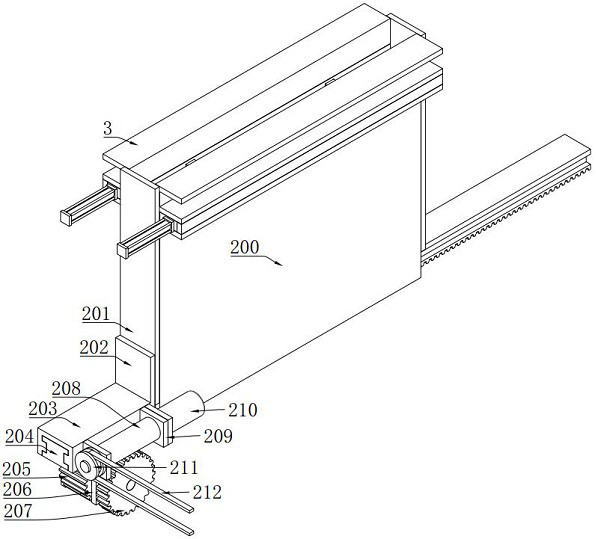

[0037] Such as figure 1 As shown, a material box alternate conveying device for IC detection includes a feeding mechanism 1 , a feeding mechanism 2 , a lower stop mechanism 3 and a feeding mechanism 4 . The quantity of unloading mechanism 2 is two, and is all arranged on the lower end of feeding mechanism 1, and the quantity of downstop mechanism 3 is four, and every two downstop mechanisms 3 are all arranged on the upper end of one unloading mechanism 2, The feeding mechanism 4 is located at the discharge end of the lower end of the unloading mechanism 2 .

[0038] The feeding mechanism 1 is used for placing multiple rows of IC magazines, and transfers the magazines filled with ICs to the unloading mechanism 2. The unloading mechanism 2 is used for placing IC magazines in a single row. And from its lower end, a single material box filled with IC is pushed onto the feeding mechanism 4, the lower stop mechanism 3 is used for the support of a single IC material box filled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com