A material box alternate conveying device for ic detection

A technology for conveying devices and materials used in transportation and packaging, conveyor objects, and unstacking of objects, etc., can solve problems such as increasing the work intensity of operators, idling of detection equipment, and the impact of detection efficiency, so as to reduce the cost of placement Frequency, reduce the frequency of feeding, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

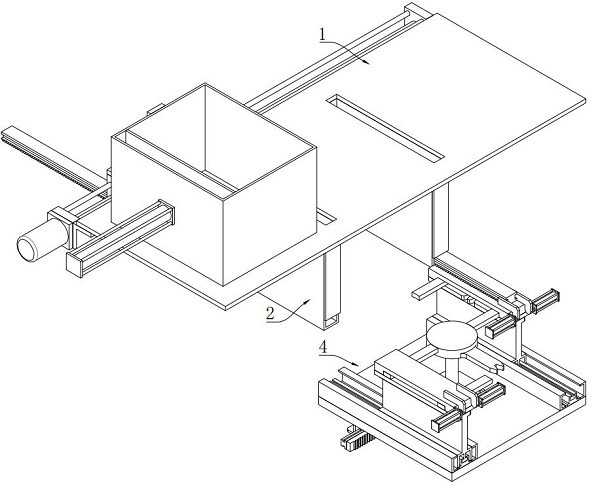

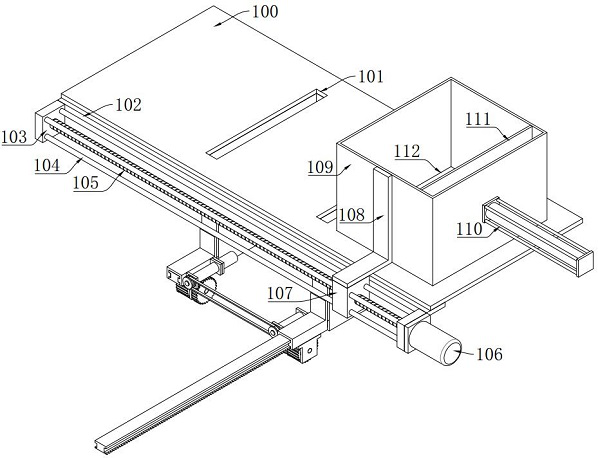

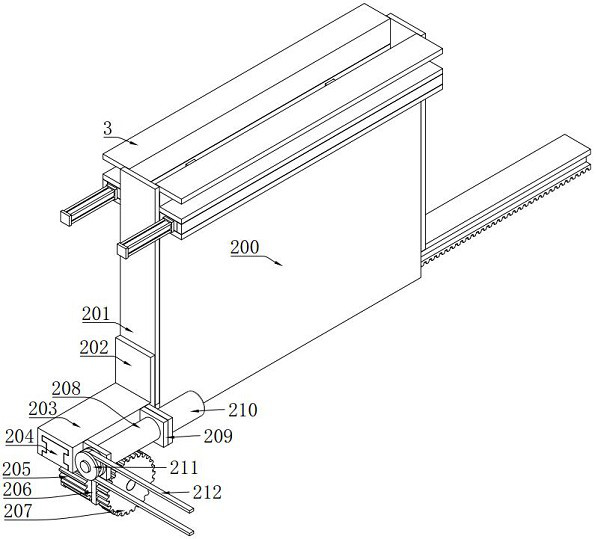

[0037] like figure 1 As shown, an alternate conveying device for IC detection material boxes includes a feeding mechanism 1 , a feeding mechanism 2 , a lower blocking mechanism 3 and a feeding mechanism 4 . The number of unloading mechanisms 2 is two, and they are both arranged at the lower end of the feeding mechanism 1, the number of lower blocking mechanisms 3 is four, and every two lower blocking mechanisms 3 are arranged on the upper end of one unloading mechanism 2, The feeding mechanism 4 is arranged at the discharging end of the lower end of the feeding mechanism 2 .

[0038] The feeding mechanism 1 is used for the placement of multiple rows of IC cartridges, and the cartridges filled with ICs are transferred to the unloading mechanism 2, which is used for the placement of a single row filled with IC cartridges, And from its lower end, push a single cartridge filled with IC to the feeding mechanism 4, the lower block mechanism 3 is used for the support of the single I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com