A kind of power battery dismantling equipment and method

A power battery and equipment technology, applied in the field of power battery dismantling equipment, can solve the problems of non-continuous production process, contact with battery waste liquid, and explosion of used batteries, etc., and achieve the effects of saving manpower, reliable separation, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

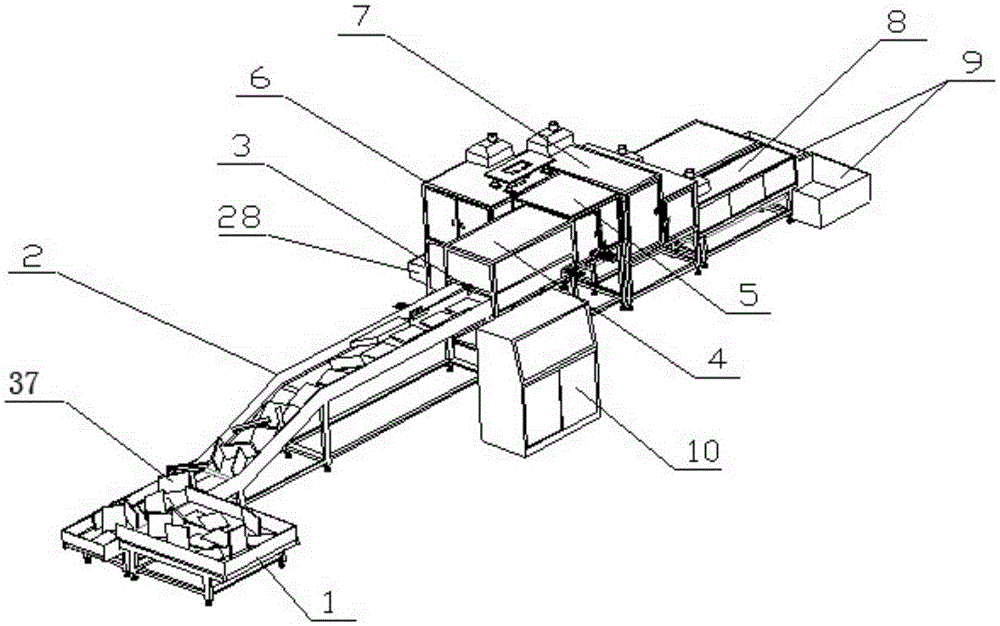

[0052] Such as figure 1 , a power battery dismantling equipment, including: a storage conveyor, an adjustment conveyor, a video system, an automatic adjustment feeding mechanism, a cutting and feeding mechanism, an automatic cutting mechanism, an automatic separation mechanism, a discharge conveyor, a storage box and electric console. The electric control panel is connected with the aforementioned mechanisms except the material storage box to realize the automatic control of the equipment.

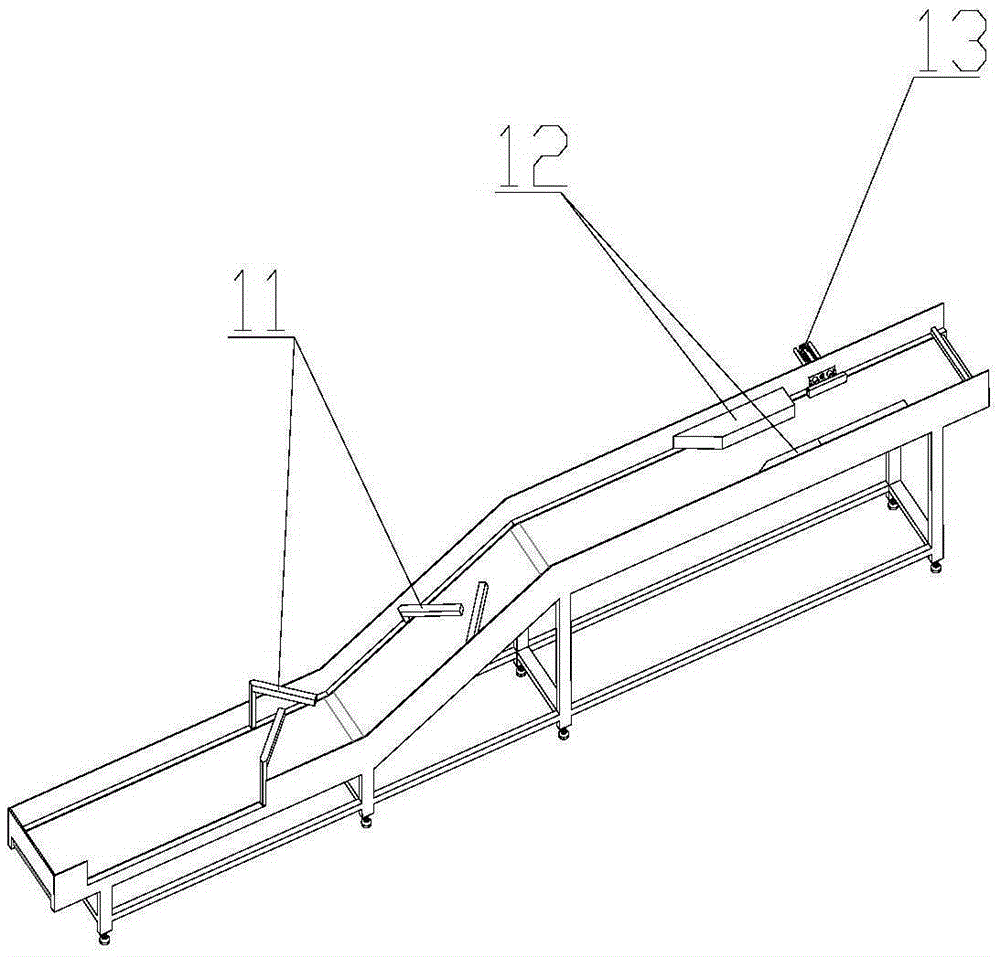

[0053] Such as image 3 , The adjustment conveyor is equipped with a conveyor belt, a push-down device, a guide block, and a leveling device, which are used to automatically adjust the placement of the power battery. The power battery is placed on the conveyor belt for transportation. The push-down device straddles and is erected on the conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com