A slow-release liquid-carrying sand-carrying foam discharge agent and its preparation method

A foam discharge agent and slow technology, which is applied in the field of slow release liquid-carrying sand-carrying foam discharge agent and its preparation, can solve the problems of aggravating the sand production degree of gas wells, large seasonal temperature difference, increasing production costs, etc., and achieves wide application conditions. , lasting performance, ensuring the effect of normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

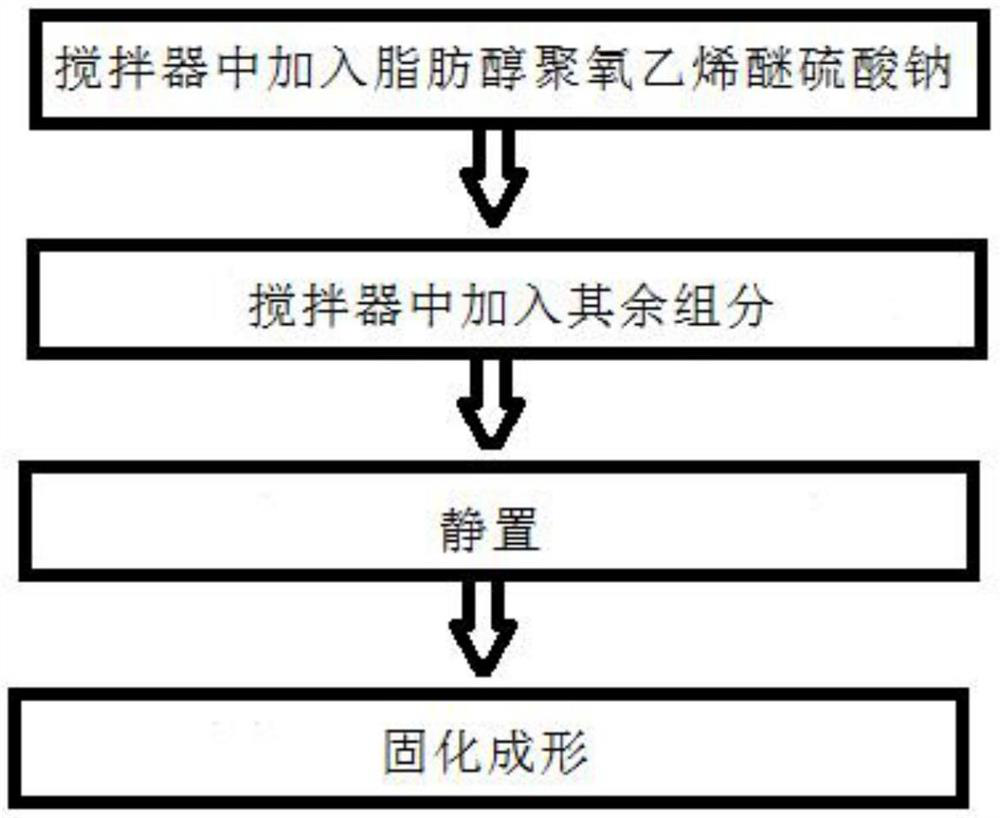

Method used

Image

Examples

Embodiment 1

[0029] A slow-release liquid-carrying and sand-carrying foam discharge agent, which is made of the following components in parts by weight: 2-10 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 10-40 parts of cocamidopropyl betaine, fat 10-30 parts of alcohol polyoxyethylene ether, 10-40 parts of octadecyl dihydroxyethyl betaine, 5-20 parts of cetyltrimethylammonium bromide, 2-10 parts of polyvinyl alcohol; casing 5 ~20 servings.

[0030] In actual use, according to the water and sand production of the gas well, the foam row rods are put into the wellbore at a ratio of 1:3 to 6, the well is shut down for several hours, and the well is started for production according to the pressure recovery.

[0031] In the present invention, 2 to 10 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 10 to 40 parts of cocamidopropyl betaine, 10 to 30 parts of fatty alcohol polyoxyethylene ether, 10 to 30 parts of fatty alcohol polyoxyethylene ether, Hydroxyethyl betaine...

Embodiment 2

[0045] A slow-release liquid-carrying sand-carrying foam discharge agent, the parts by weight of each component are: fatty alcohol polyoxyethylene ether sodium sulfate: 5 parts; cocamidopropyl betaine: 35 parts; fatty alcohol polyoxyethylene ether : 15 parts; octadecyl dihydroxyethyl betaine: 20 parts; cetyltrimethylammonium bromide: 10 parts; polyvinyl alcohol: 5 parts; sausage casing: 10 parts.

Embodiment 3

[0047] A slow-release liquid-carrying and sand-carrying foam discharge agent, the parts by weight of each component are: fatty alcohol polyoxyethylene ether sodium sulfate: 10 parts; cocamidopropyl betaine: 25 parts; fatty alcohol polyoxyethylene ether : 10 parts; octadecyl dihydroxyethyl betaine: 30 parts; cetyltrimethylammonium bromide: 5 parts; polyvinyl alcohol: 5 parts; sausage casing: 15 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com