High water-resistant aquatic organism anti-stress attractant additive and preparation method thereof

An anti-stress and additive technology, applied in food processing, application, animal feed, etc., can solve the problem of single components and functions, no dosage form of high water resistance and anti-dissolution products, undisclosed high water resistance gel production process, etc. problems, to achieve the effect of improving the food attractant, improving the body's immunity and anti-stress ability, and improving the body's free radical metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

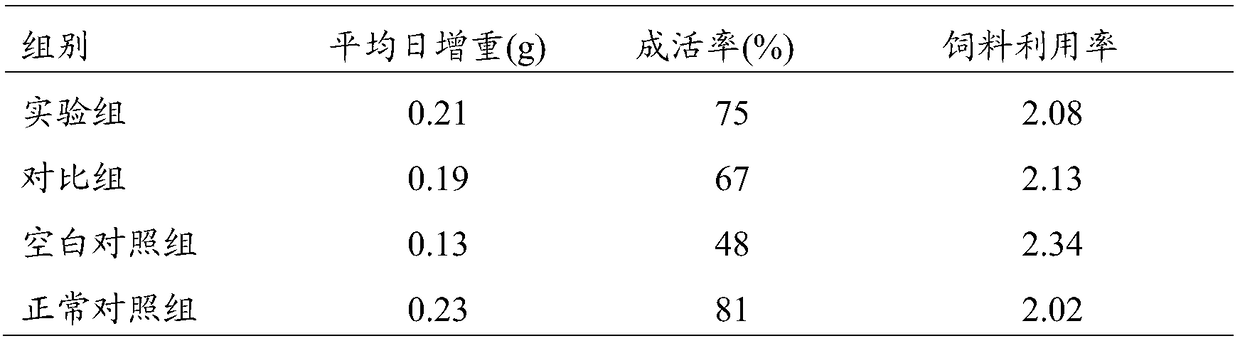

Embodiment 1

[0058] 1) Take 5 parts of dried astragalus, 3 parts of licorice, 4 parts of coptis, 6 parts of isatidis, 3 parts of Chinese gall, and 2 parts of tangerine peel according to the weight ratio, mix and grind to obtain 230g of raw materials, pass through a 60-mesh sieve, and add 10 times Weight of distilled water and compound enzyme composed of xylanase and cellulase for enzymolysis, in which xylanase 120U / ml, cellulase 80U / ml in the solution, shake enzymolysis at pH 5.0, 60°C for 5h , heat and decoct for 30min after enzymolysis, then drop to room temperature to filter and concentrate the filtrate to obtain 350ml of concentrated enzymolysis solution, and dry the filter residue; mix the dried medicinal material filter residue with the broken corn pollen in a mass ratio of 1:2 Place in an extractor, add 3L of ethanol with a volume fraction of 90%, heat to 60°C and extract twice under ultrasonic reflux; after the extraction is completed, filter, combine the filtrate and evaporate and ...

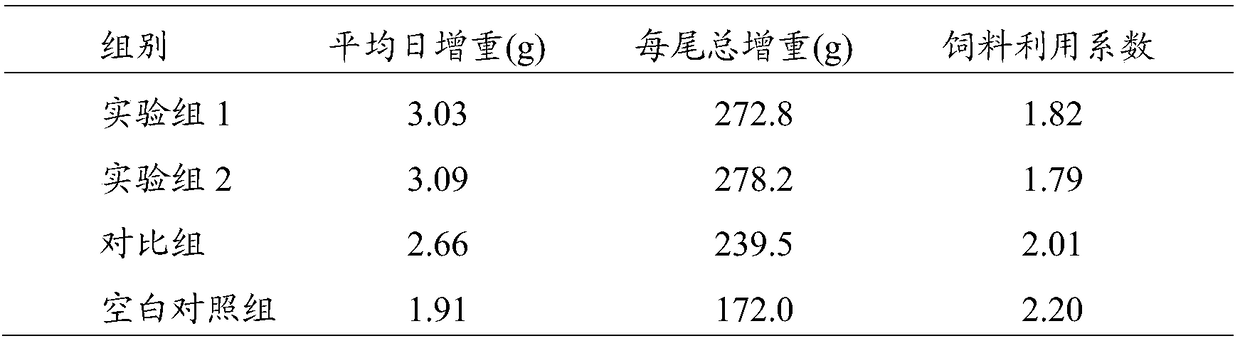

Embodiment 2

[0066] 1) Take 8 parts of astragalus, 5 parts of licorice, 5 parts of coptis, 6 parts of isatidis, 4 parts of gallnut, and 3 parts of tangerine peel, mix and grind them through an 80-mesh sieve to obtain 310 g of raw materials, add 10 times the weight of distilled water, and add xylanase To 150U / ml, add cellulase to 80U / ml. Shake enzymolysis at pH 5.5 at 60°C for 6 hours, heat and decoct for 40 minutes after enzymolysis, then cool down to room temperature, filter and concentrate the filtrate to obtain 350ml of concentrated enzymolysis solution, and dry the filter residue.

[0067] Mix the dried medicinal material filter residue and broken wall corn pollen at a mass ratio of 1:3, put it in the extractor, add 5L of 80% ethanol solution, heat to 70°C and extract twice under ultrasonic reflux; after the extraction is completed, filter and combine the filtrate And carry out evaporation and concentration to obtain 1.3L of alcohol extract; combine it with the above-mentioned concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com