Wire routing system in bicycle

A technology for internal wiring and bicycles, applied in bicycle frames, bicycle accessories, steering mechanisms, etc., can solve problems such as easy damage or aging, and achieve the effect of simplifying the frame structure, reducing after-sales maintenance costs, and enhancing connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

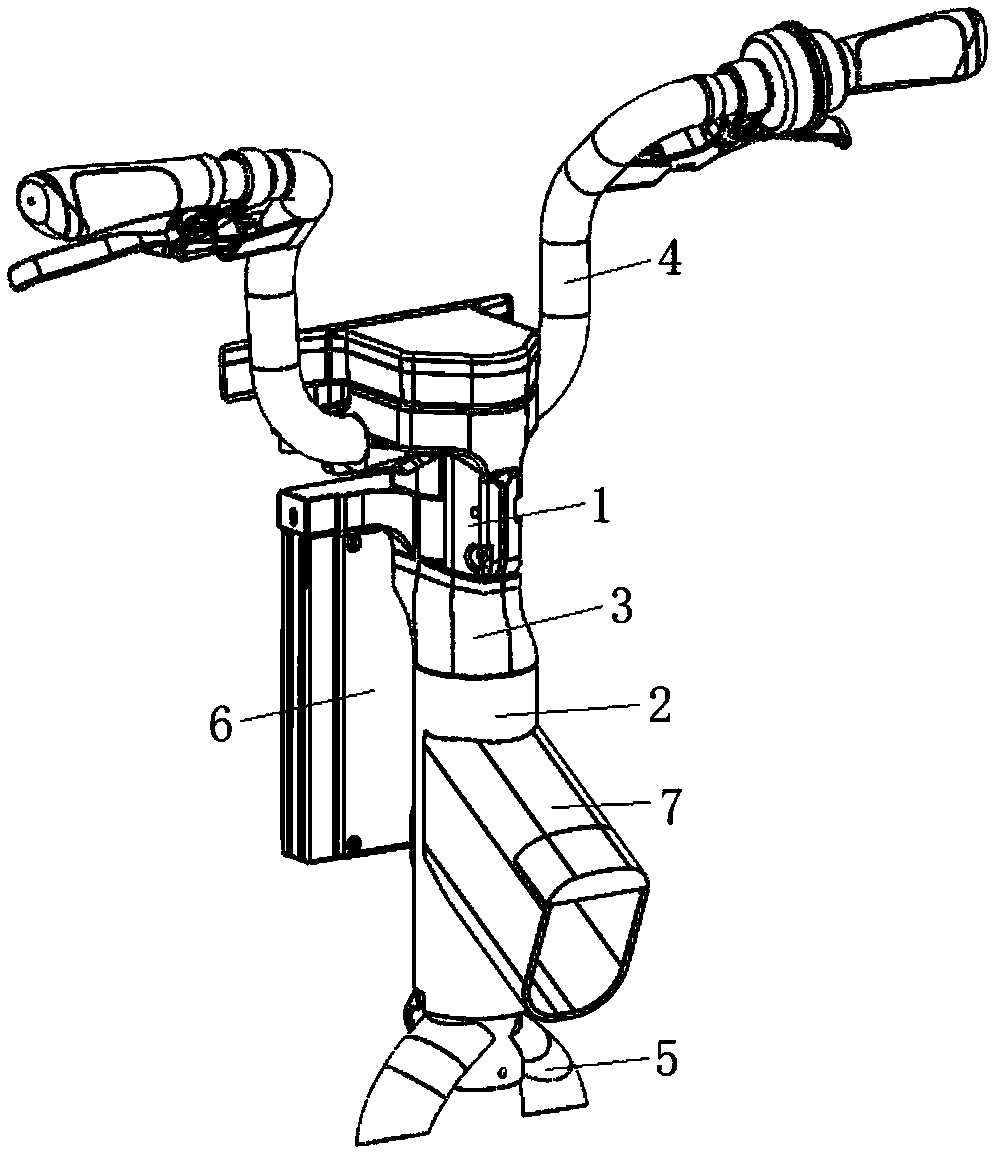

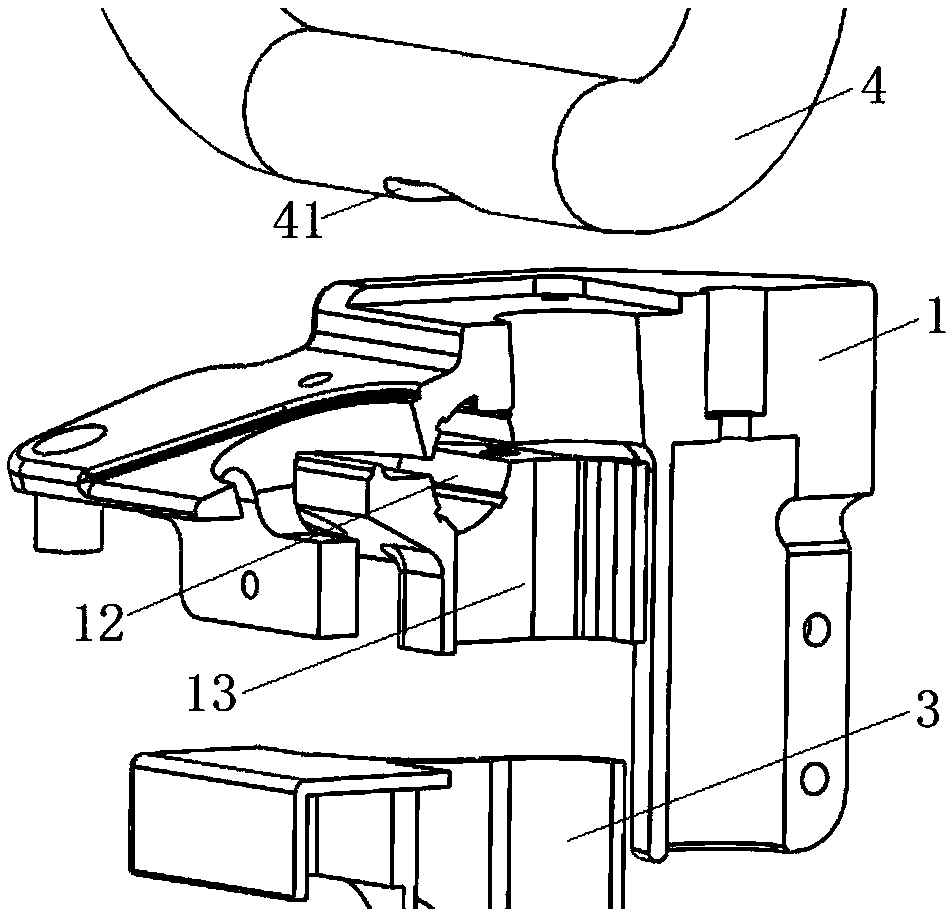

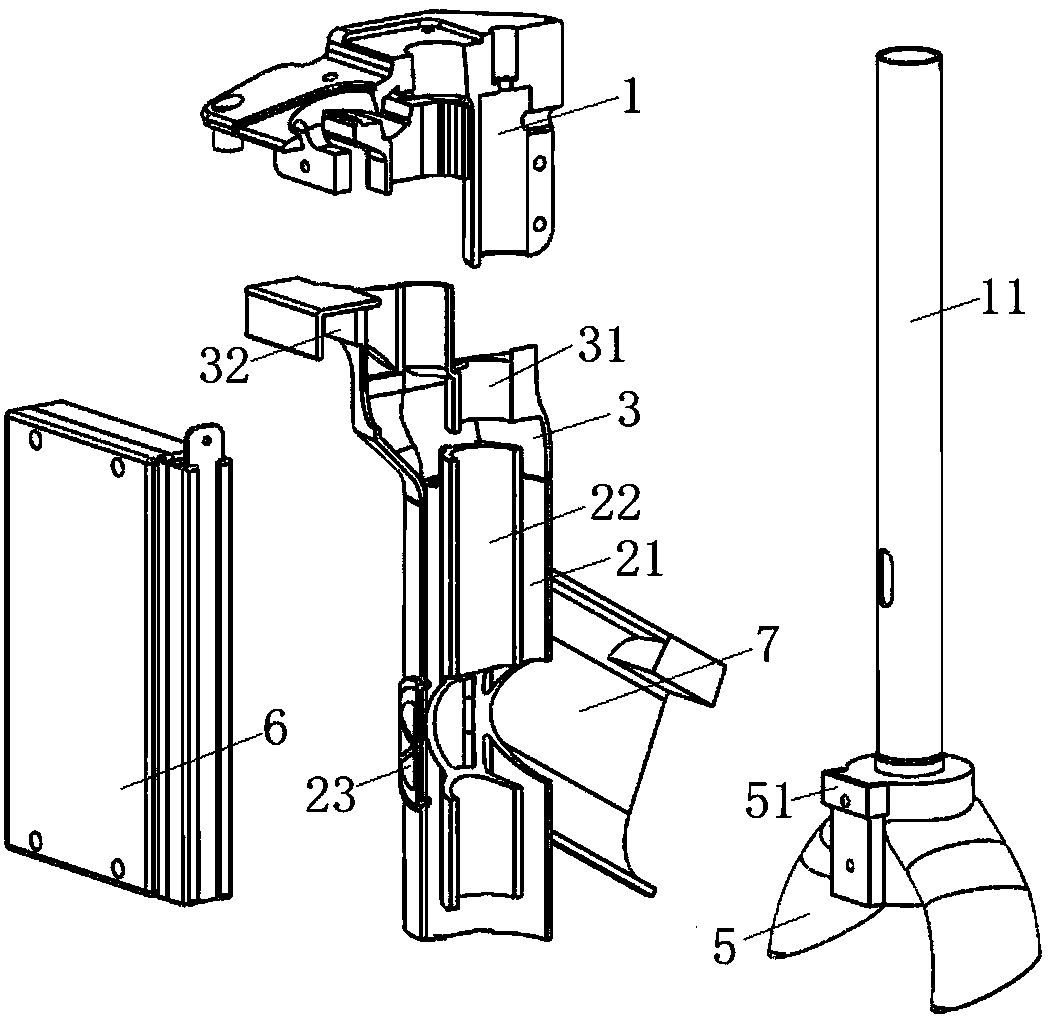

[0026] As shown in the attached drawings, a cable routing system in a bicycle is characterized in that: it includes a stem 1 and a head pipe 2; a wire hub device 3 is arranged between the stem 1 and the head pipe 2; the stem 1 , The interior of the head pipe 2 and the hub device 3 are communicated with each other; the interior of the stem 1 and the handle 4 are communicated with each other; ; as attached image 3 As shown, the lower end of the stem 1 is fixedly provided with a steering tube 11; the steering tube 11 passes through the hub device 3 and the head tube 2 downward in turn and is fixedly connected to the front fork 5; to ensure that the various structures of the bicycle function properly, Various wiring harnesses are essential. For ordinary bicycles, common wiring harnesses include brake lines, transmission control lines, etc., while for motorcycles, wiring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com