Silent type air locking and feeding valve

A feeding valve and air-locking technology, which is applied in the field of valves and machinery, can solve the problems of motor power overload adjustment, large gap between impeller and valve body, valve jamming, etc., and achieves long service life, simple operation and maintenance, and convenient equipment installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

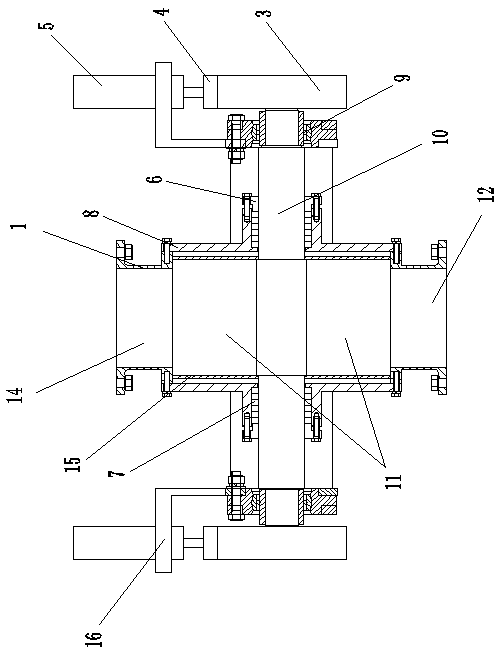

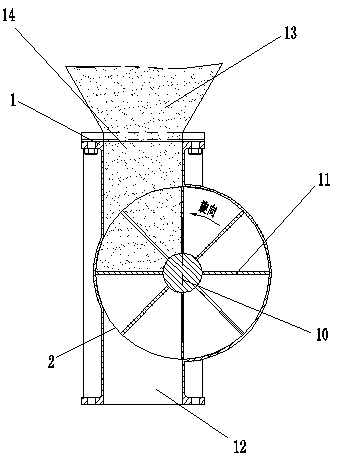

[0017] The technical solutions of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

[0018] See attached Figure 1-2 , the impeller 2 in the feed valve is installed on the valve end cover 8 through the impeller bearings 9 installed outside the two ends of the impeller shaft 10, the valve end cover 8 is fastened to the valve body 1 with bolts, and the valve end cover 8 is close to the impeller 2 The installed shaft seal 7 and shaft seal gland 6 are used for sealing the valve body 1 . The blades 11 on the impeller 2 and the baffles 15 at both ends form an integral body with the impeller shaft 10, and the three components form a plurality of material tanks on the impeller 2 that can accommodate certain materials. The material enters the feed valve through the hopper 13 and the valve inlet 14. Since the impeller shaft 10 installed on the impeller 2 has a certain eccentricity with respect to the vertical ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com