Multi-axial loading stress corrosion testing equipment

A technology of stress corrosion and test equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., to achieve the effect of increasing test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

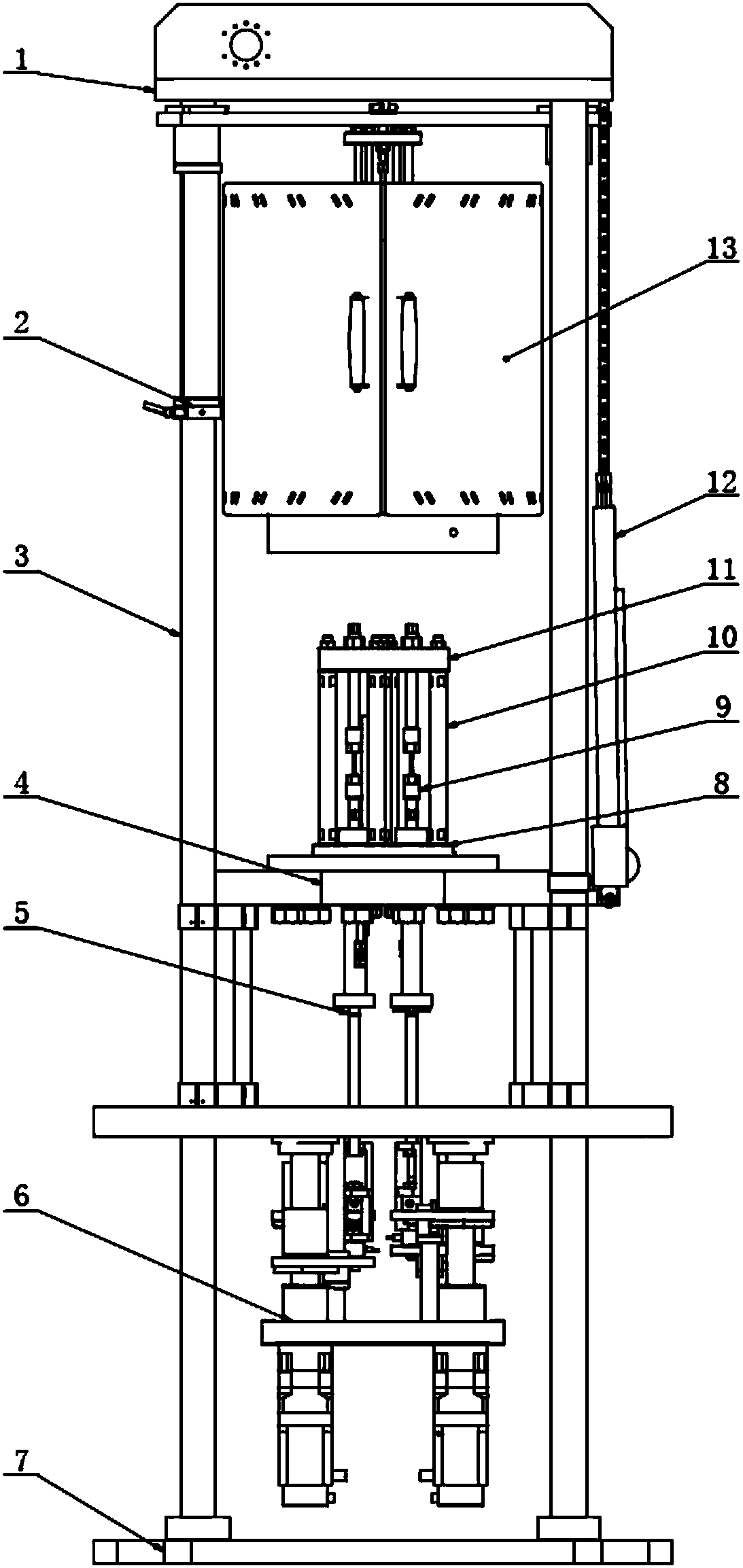

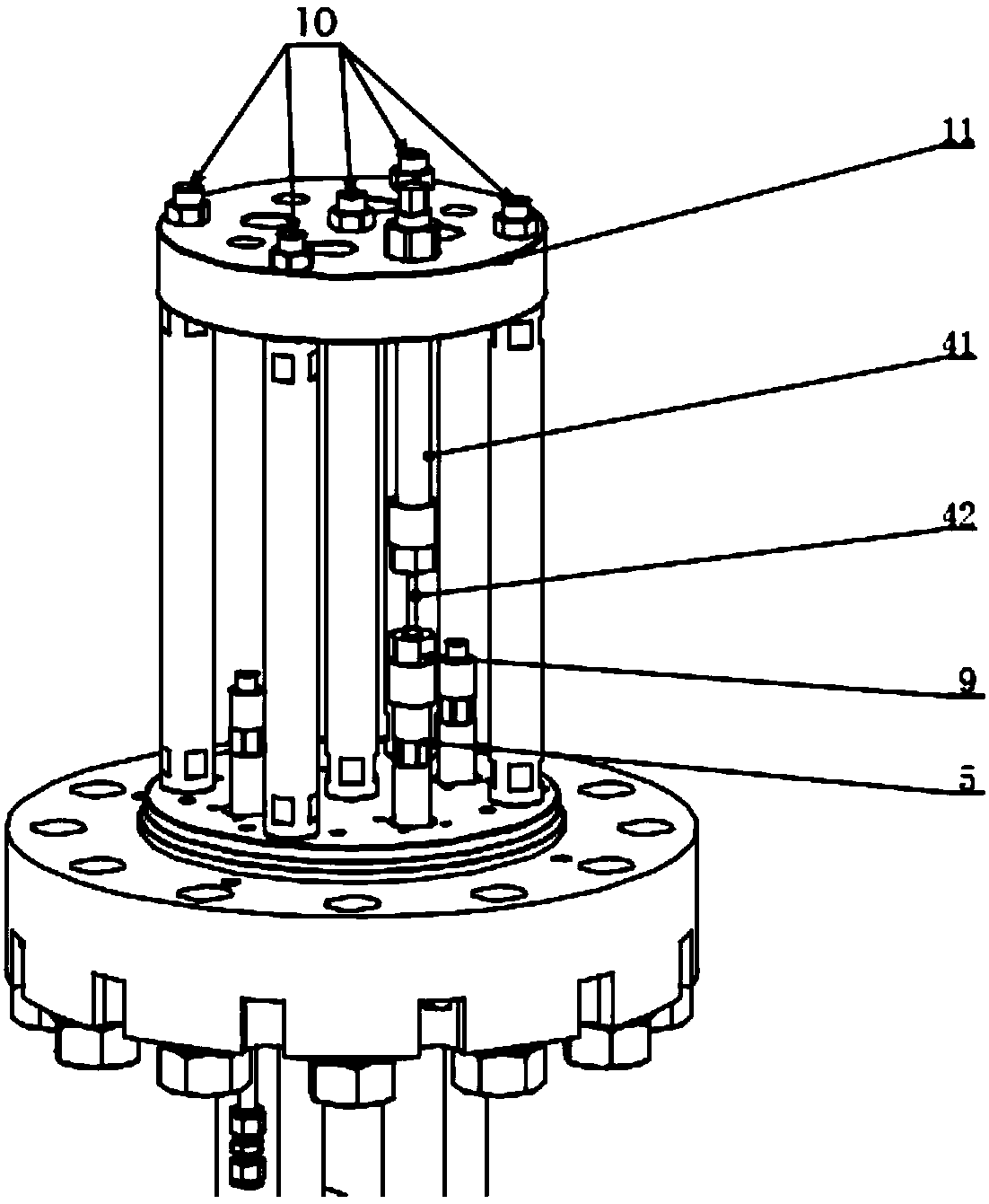

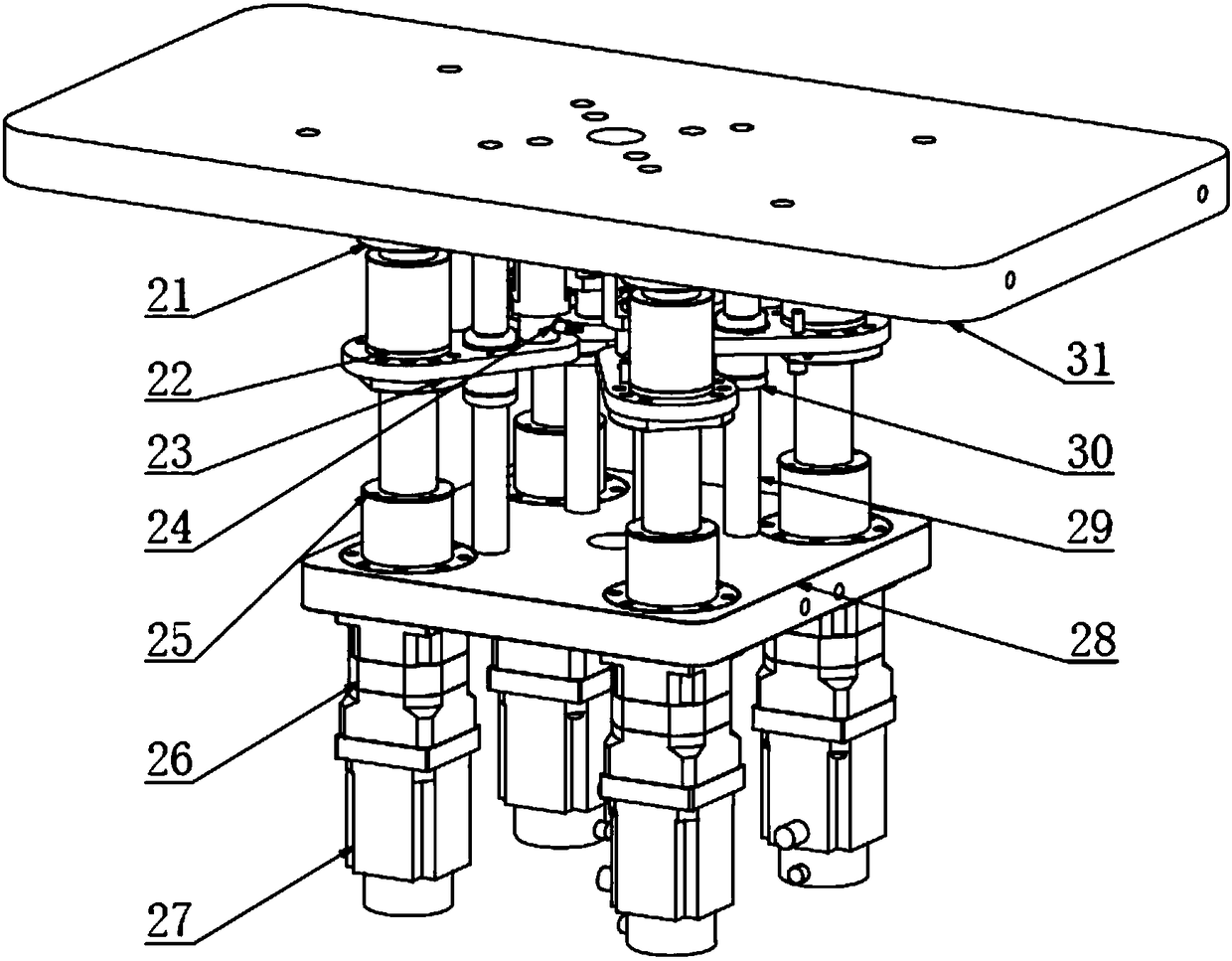

[0037] Such as figure 1As shown, a multi-axial loading stress corrosion test equipment includes a top beam 1, a column 3, a bottom plate 7, a multi-axial loading device 6, a tie rod 5, an installation mechanism in a kettle, an electric push rod 12, a kettle body and a heating furnace 13. The bottom plate 7 is arranged at the bottom of several columns 3 , and the top beam 1 is arranged at the top of several columns 3 . The multi-axis loading device 6, the pull rod 5, the installation mechanism in the kettle and the kettle body are installed between several columns 3 from bottom to top. The kettle body is installed in the heating furnace 13, and the electric push rod 12 is connected with the heating furnace 13, and the heating furnace 13 is lifted or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com