Continuous nondestructive testing device for local defects of superconducting cable

A technology for superconducting cables and local defects, applied in the direction of material magnetic variables, can solve the problems of uneven residual magnetic field, inability to detect local defects in superconducting cables, etc., to achieve the effect of ensuring performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

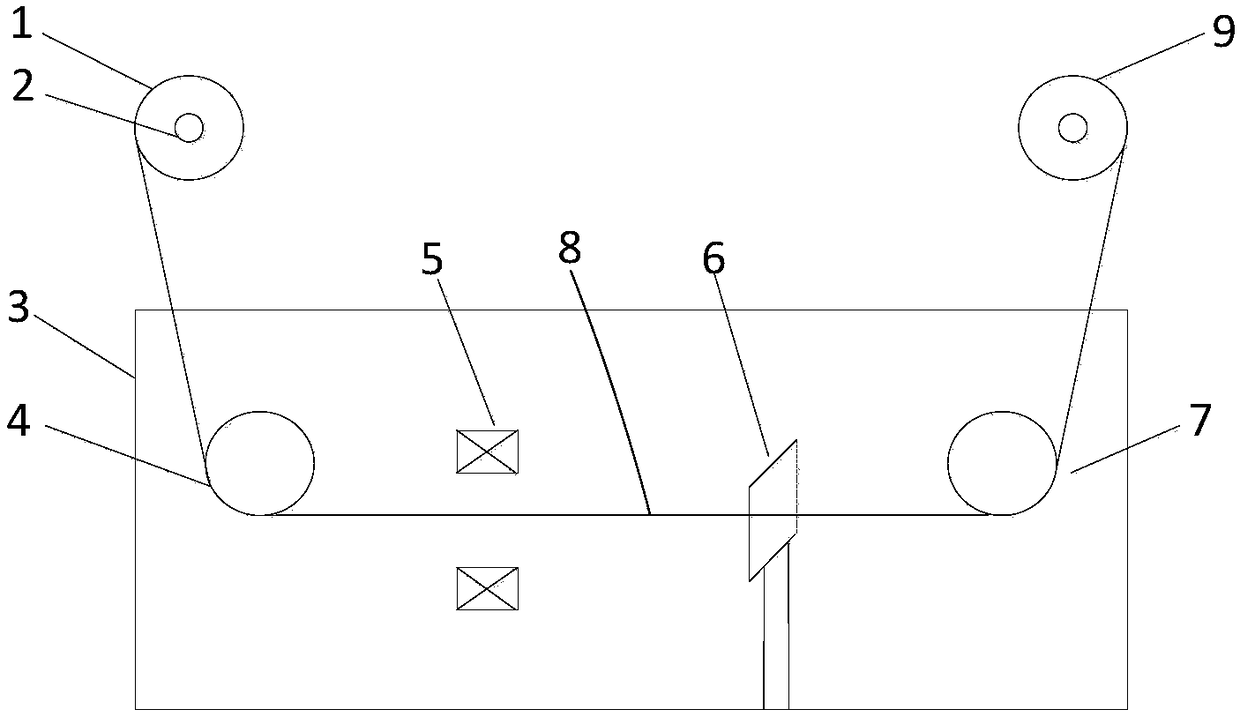

[0018] figure 1 It is shown that a specific embodiment of the present invention is a continuous non-destructive testing device for local defects of superconducting cables, which is characterized by:

[0019] The pay-off reel 1 and the take-up reel 9 are respectively installed on the upper left and upper right of the Dewar 3, the shaft of the pay-off reel 1 is connected with the damper 2, and the shaft of the take-up reel 9 is connected with the stepping motor;

[0020] Guide wheel 4, excitation coil 5, magnetic field detector 6, guide wheel 2 7 are installed in Dewar 3 from left to right; the magnetic field detector 6 has four rows of front, rear, upper and lower Hall Halls. Square Hall sensor array composed of sensors;

[0021] After the superconducting cable 8 on the pay-off wheel 1 is extended, it first goes around the guide wheel 4, then passes through the center of the excitation coil 5 and the magnetic field detector 6 in turn, then goes around the guide wheel 7 and finally wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com