A method and system based on selective double-layer ensemble learning suitable for missing data completion of complex industrial process product quality indicators

An industrial process and integrated learning technology, applied in the general control system, control/regulation system, adaptive control, etc., can solve problems such as many process variables, strong coupling of variables, and large data fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

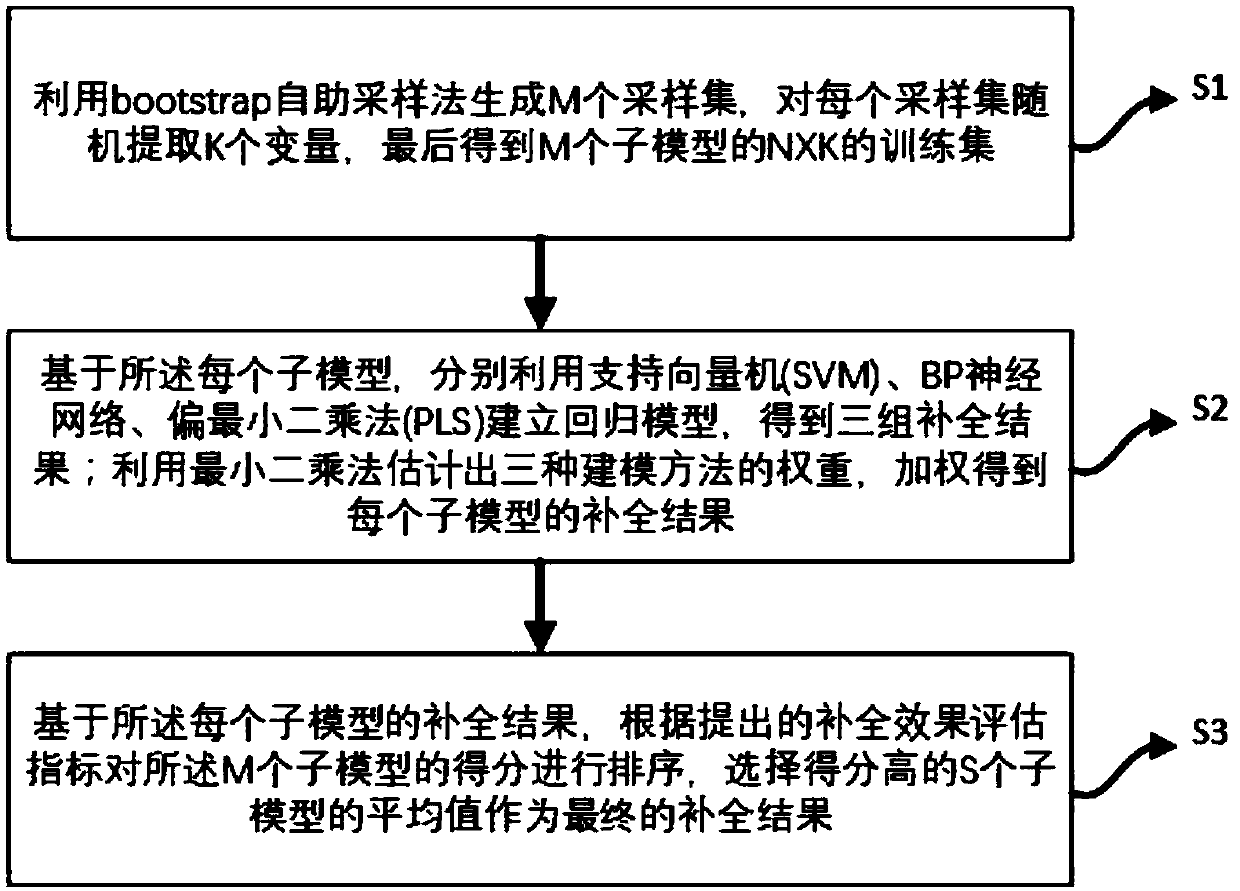

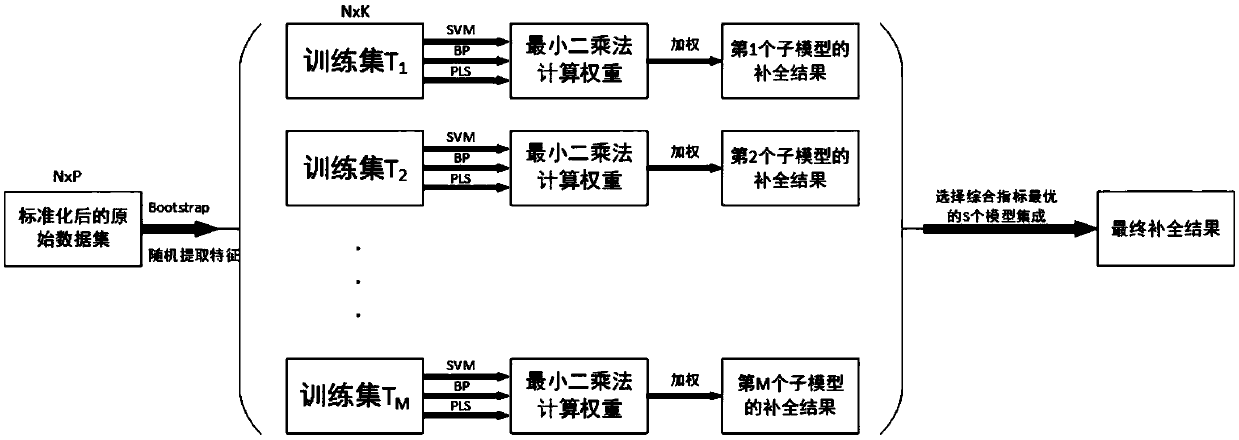

Method used

Image

Examples

specific Embodiment

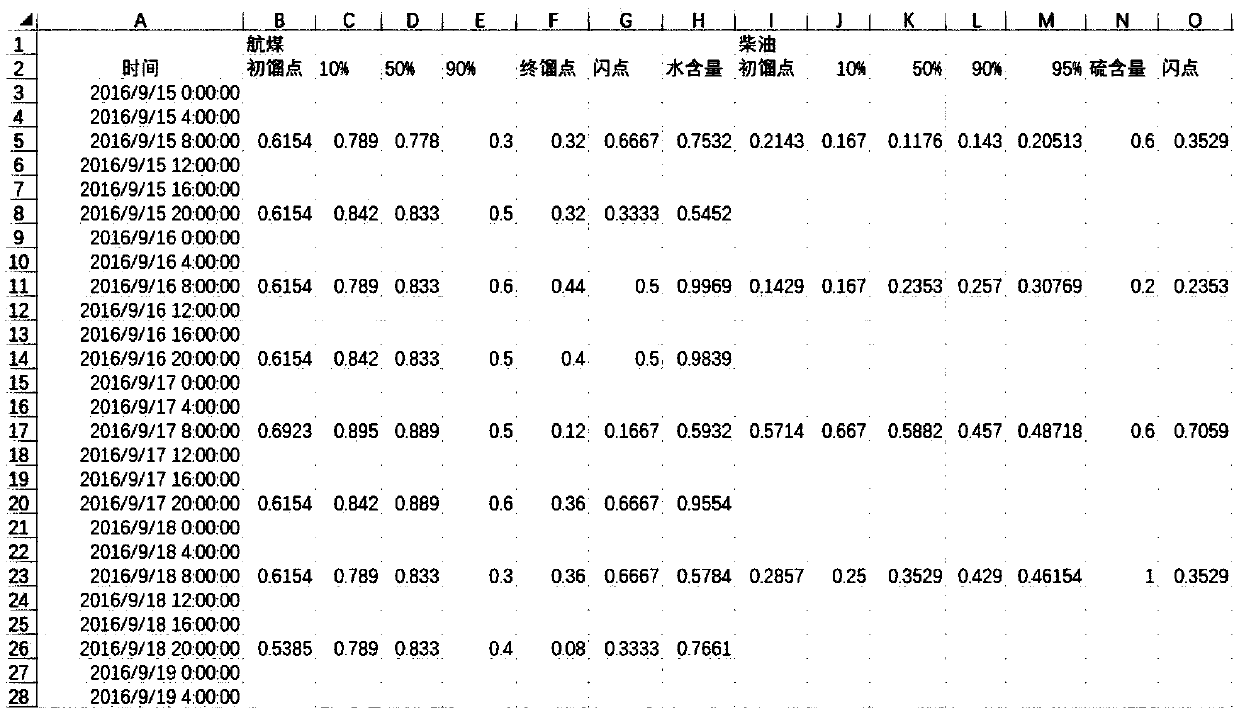

[0201] The data completion method based on selective two-layer integrated learning provided in this embodiment takes the hydrocracking process as the object, and uses the historical data of the whole process process variables and the quality index of the product oil as the initial data set. Complement the quality indicators. The hydrocracking process is complex, the detected process variables are numerous, and there is a large time lag, which leads to high dimensionality of the data set and strong nonlinearity of the model. Due to the inconsistency of the sampling frequency of the process variables and the quality index of the product oil, or the occurrence of accidents such as the failure of the product oil testing device, the quality index data of the product oil is seriously missing. Figure 5 Shows the lack of quality data samples, from Figure 5 It can be seen that most quality indicators only get a data sample in 12 hours, and some quality indicators even get a data sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com