A light-emitting diode-based light-emitting module and display panel

A technology for light-emitting diodes and light-emitting modules, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficulty in reducing the distance of light-emitting diodes, complex layout of light-emitting diodes, and unfavorable preparation of micro-pitch LED light-emitting modules, and achieves a reduction in light-emitting diodes. The effect of a small number of pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

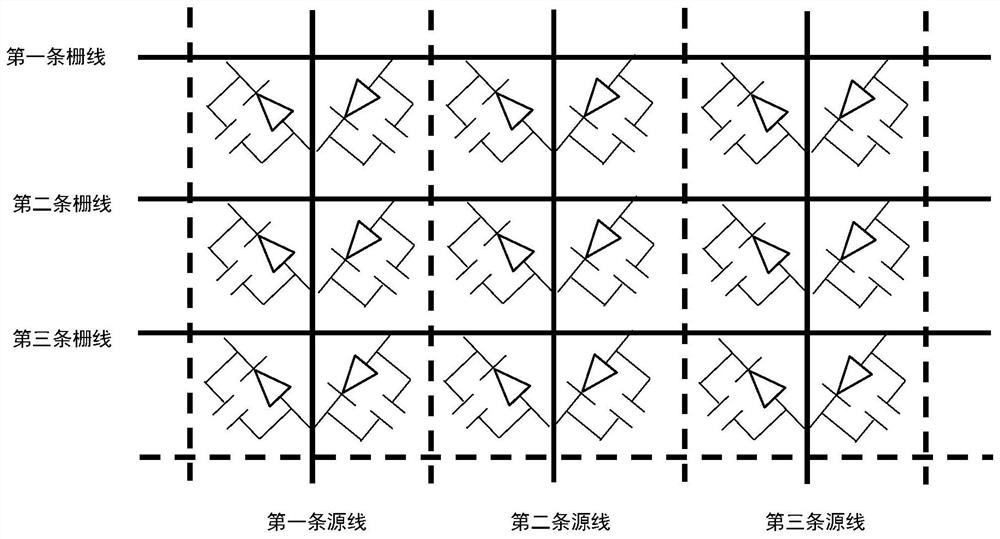

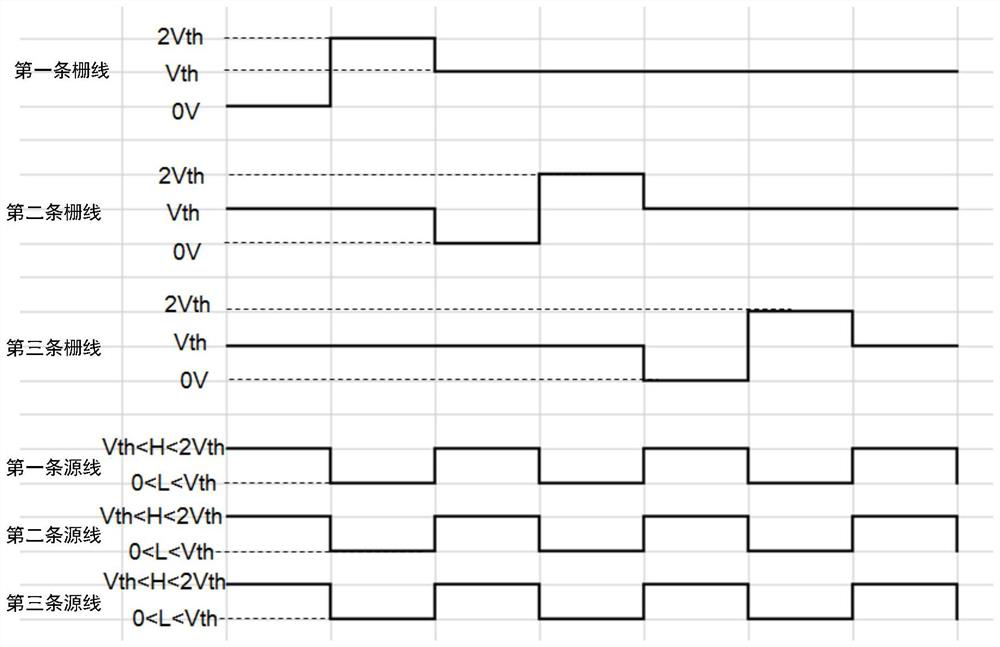

[0033] The core of the present invention is to provide a light-emitting module based on light-emitting diodes. In the prior art, usually only one LED is connected between one gate line and one source line. Under the condition that a specific number of light emitting diodes is provided, the light emitting module will have a large number of gate lines and source lines, so that the layout of the light emitting diodes is extremely complicated, and it is difficult to reduce the distance between the light emitting diodes, which is not conducive to fine pitch Preparation of LED lighting modules.

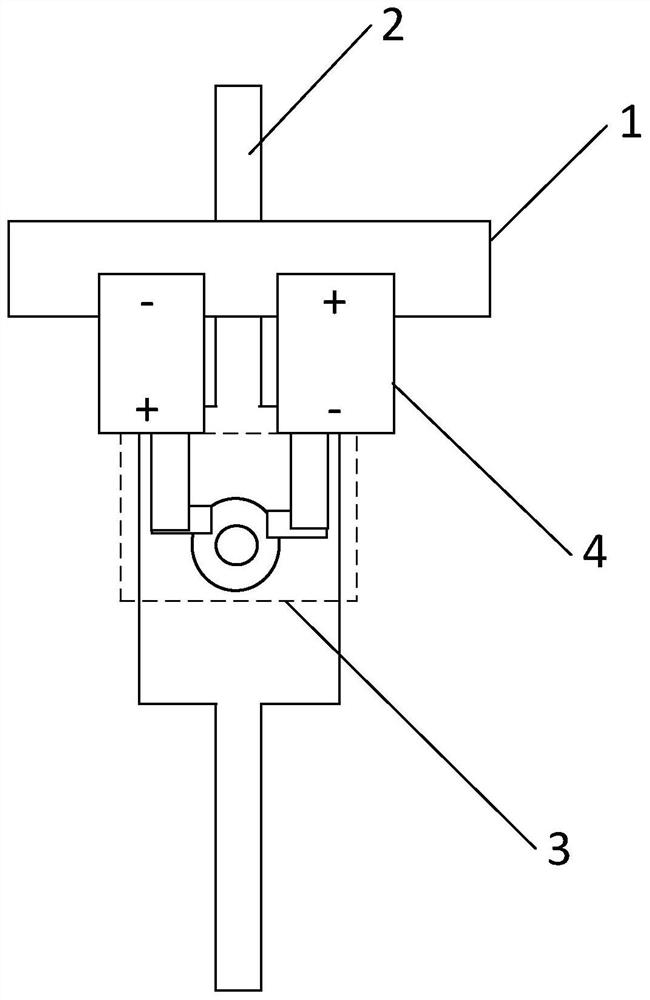

[0034] In the light-emitting module based on light-emitting diodes provided by the present invention, a drill hole penetrating through the spacer layer is provided on the first surface of the spacer layer; one electrode of the light-emitting diode is electrically connected to the grid line, and the other electrode passes through The drilled hole is electrically connected to the source line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com