Motor permanent magnet magnetic pole transition structure for improving normal electromagnetic force

A transitional structure, permanent magnet technology, applied in the shape/pattern/structure of magnetic circuit, synchronous motor with stationary armature and rotating magnet, magnetic circuit, etc. It can improve the normal electromagnetic force and normal electromagnetic force, and reduce vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Aiming at the problems caused by the current surface-mounted permanent magnet synchronous motor with discontinuous permanent magnet transition, the invention proposes a new permanent magnet magnetic pole transition structure.

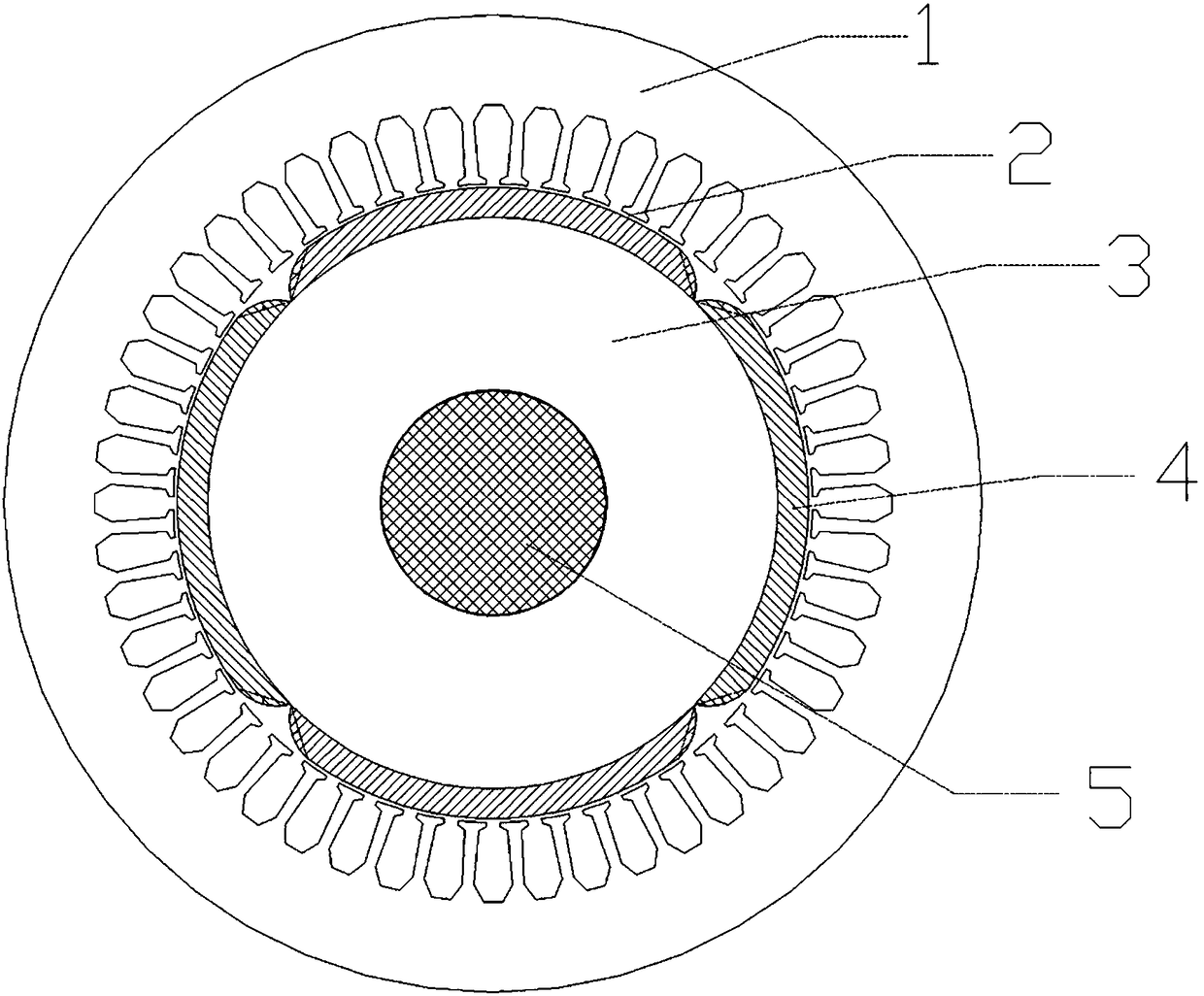

[0029] Including stator core, air gap, rotor core, permanent magnet poles, and rotating shaft.

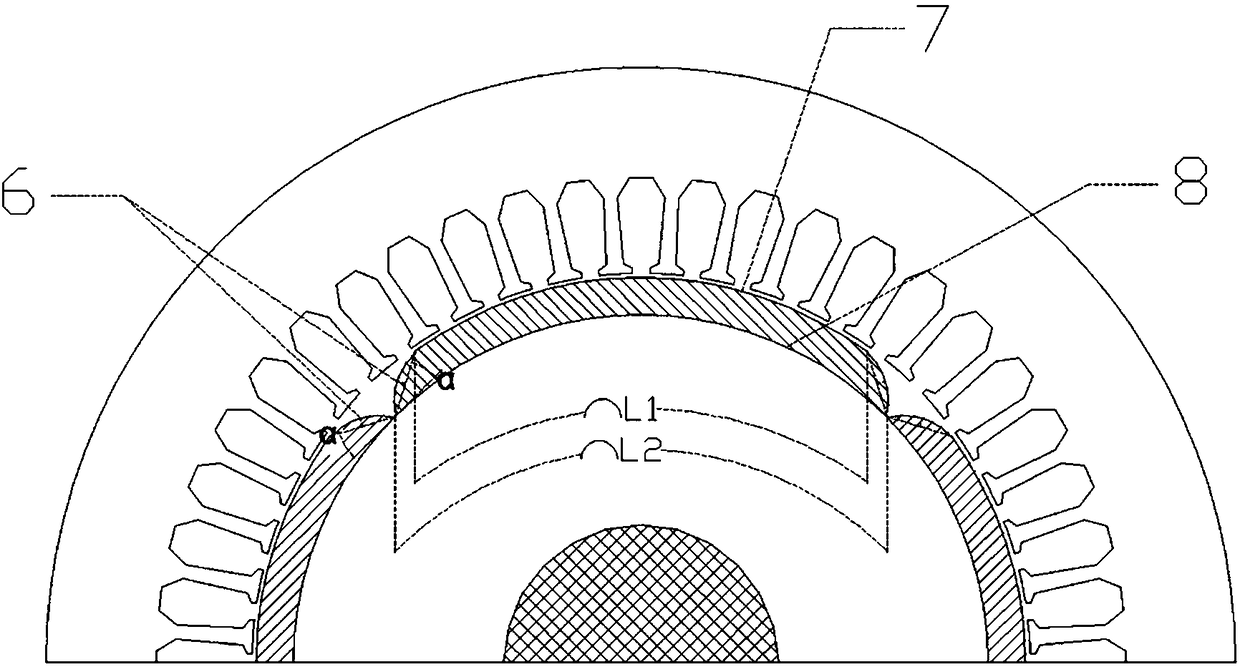

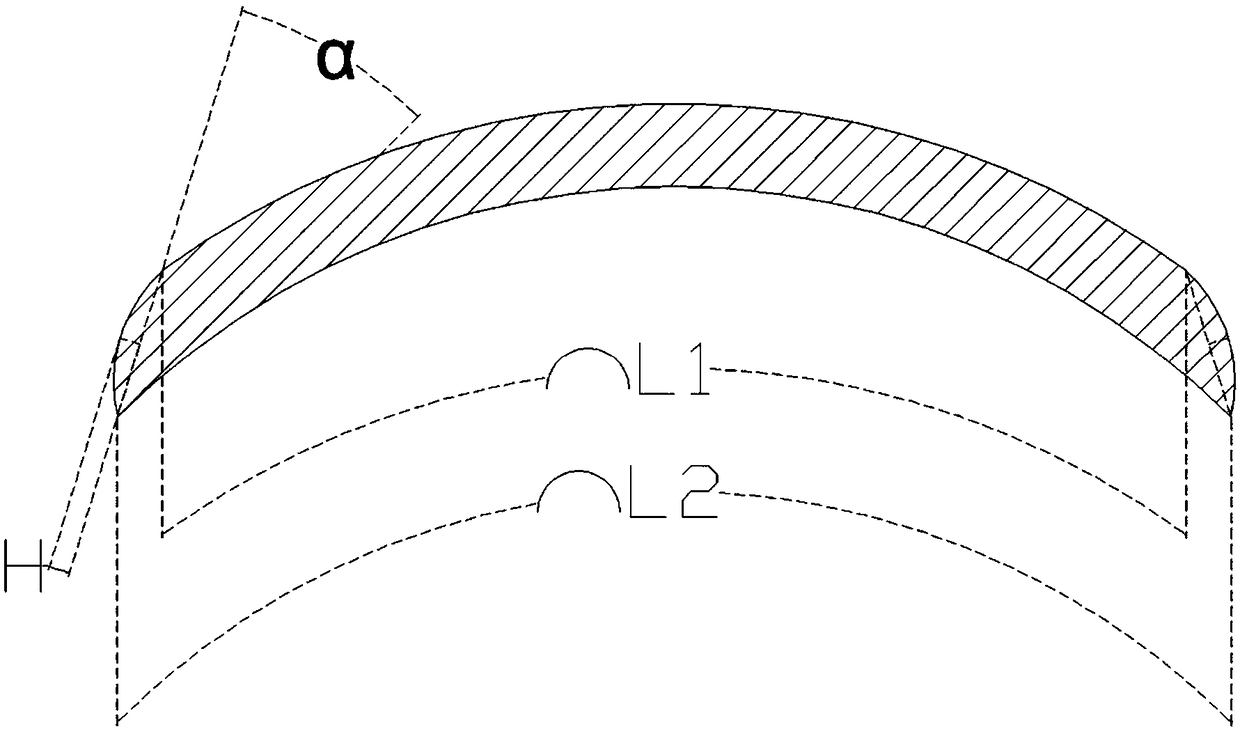

[0030] The magnetic poles of two adjacent permanent magnets of the surface-mounted permanent magnet synchronous motor intersect at the inner end of the permanent magnet magnetic pole, and the magnetic poles of the two adjacent permanent magnets only coincide at this point; the outer arc length of the permanent magnet magnetic pole of the surface-mounted permanent magnet synchronous motor is L 1 Calculate the length of the motor circuit, the inner arc length L 2 =2πR / P, and satisfy the relation L 1 2 .

[0031] Surface-mounted permanent magnet synchronous motor The angle between the chord of the magnetic pole hypotenuse of the surface-mounted permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com