Variable speed motor

A variable speed motor and motor technology, applied in the direction of DC motor speed/torque control, electromechanical devices, control systems, etc., can solve the problems of increased cross-sectional area, reduced efficiency, minimum speed limit, etc., to reduce production costs and reduce air gaps Flux density, the effect of reducing electromagnetic vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

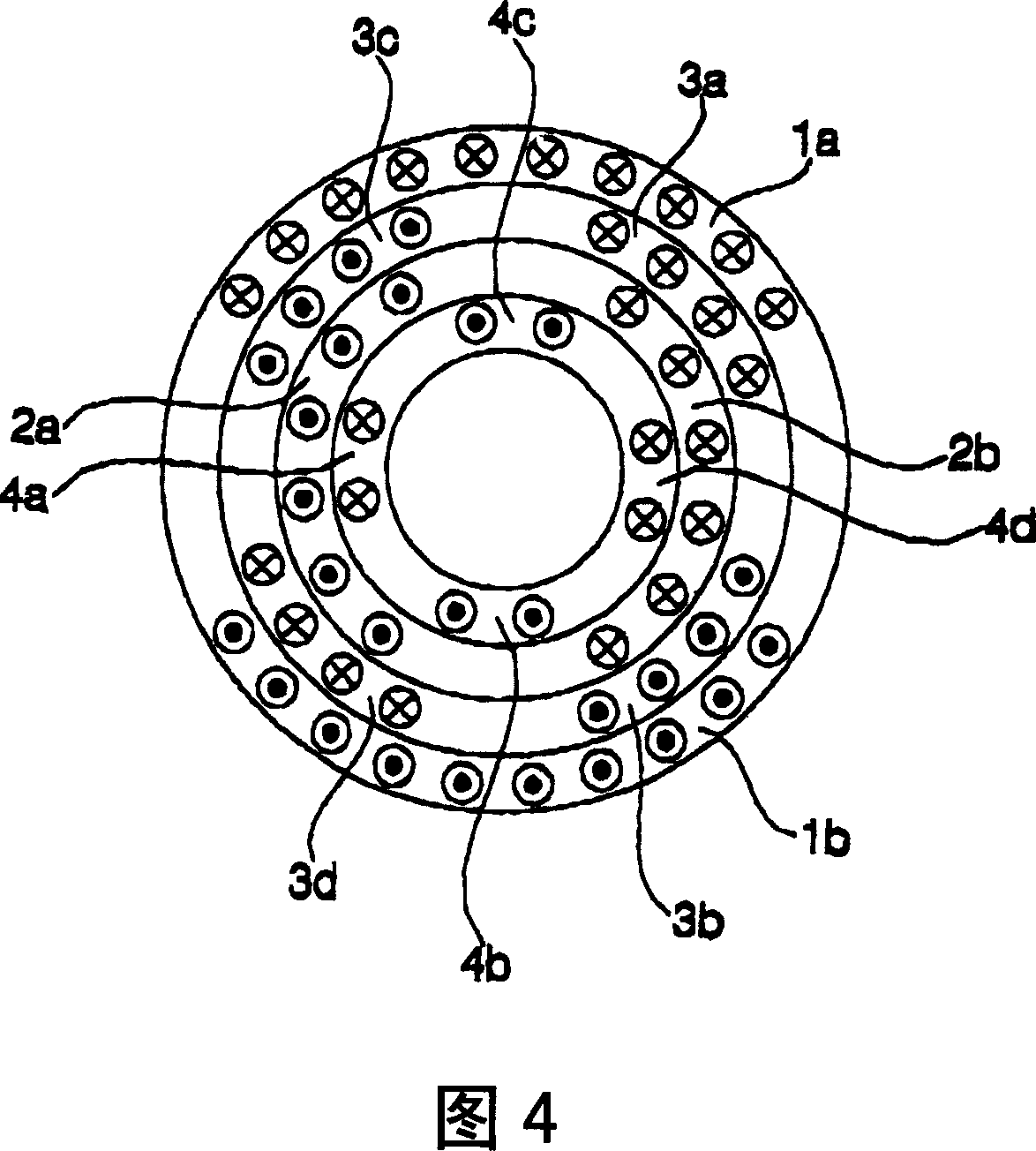

[0043] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the drawings, the same or similar elements are denoted by the same reference numerals even though they are drawn in different drawings. In the following description, a detailed description of known functions and structures incorporated herein will be omitted when it would obscure the gist of the present invention.

[0044] Hereinafter, preferred embodiments of a variable speed motor according to the present invention will be described with reference to the accompanying drawings.

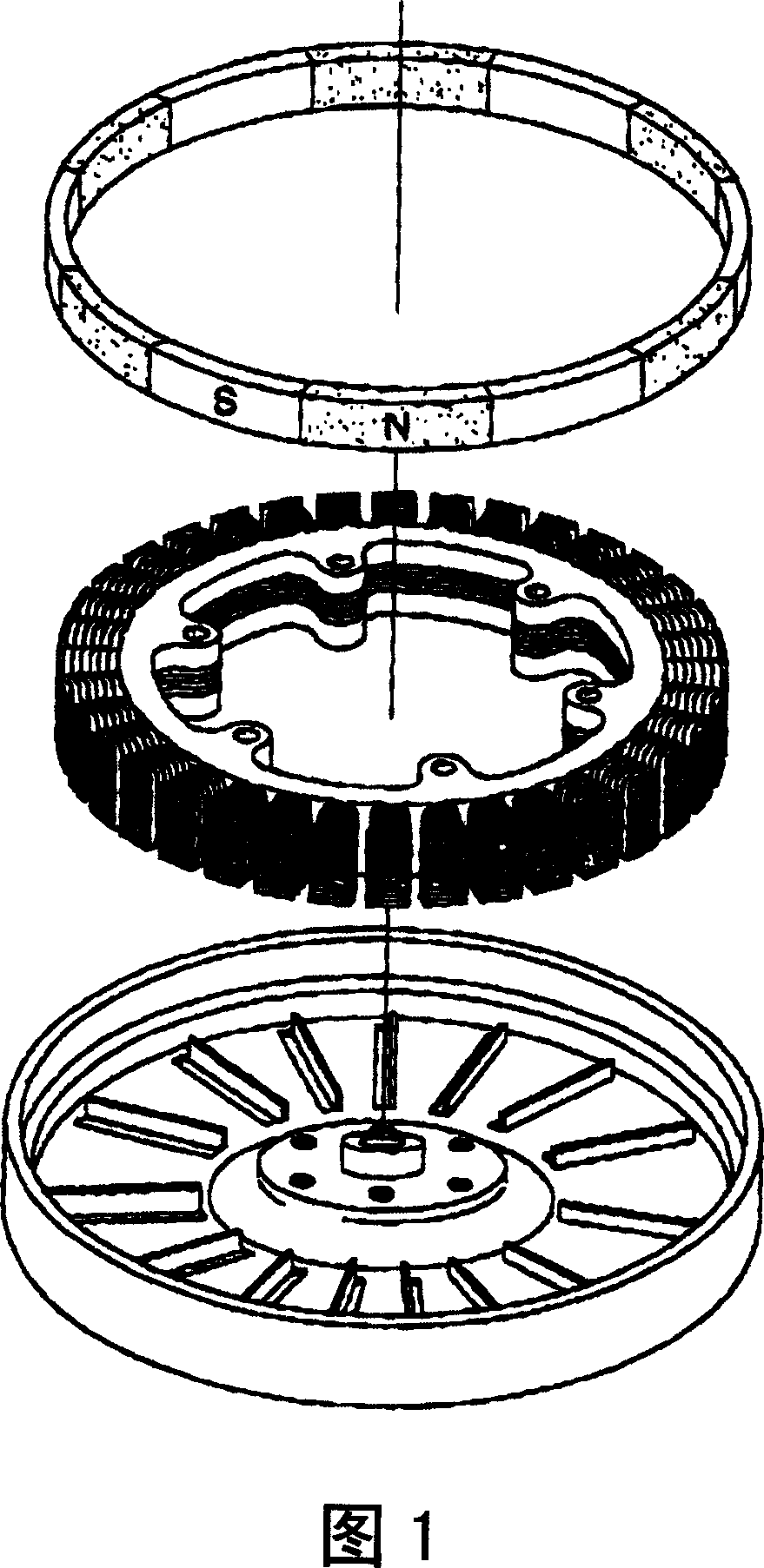

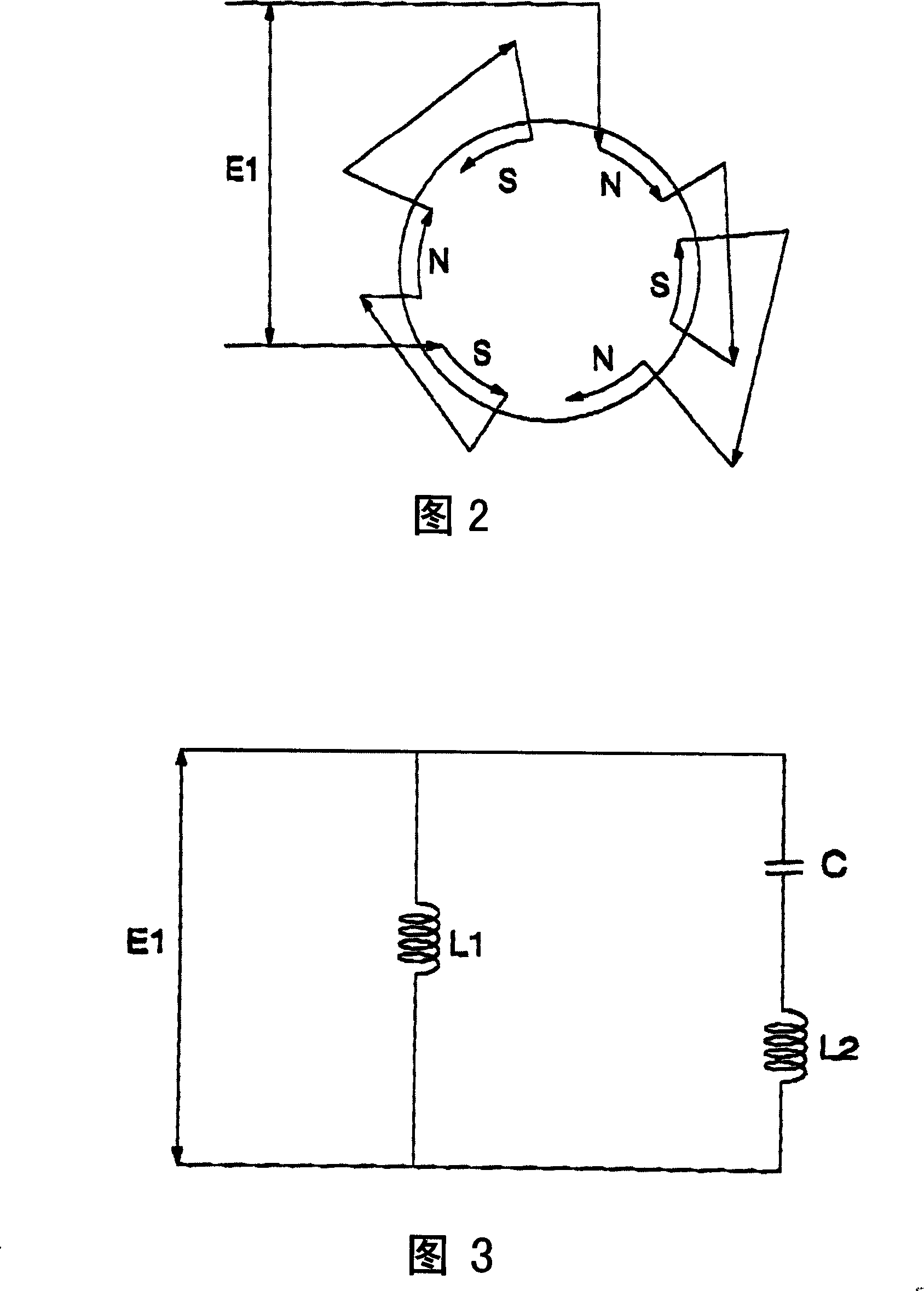

[0045] The variable speed motor according to the present invention is a single phase induction motor to which a single phase AC power signal is applied. In the case of an external rotary motor in which the rotor is installed outside the stator, the rotational radius of the external rotary motor is larger than that of the internal rotary motor, so that the tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com