Household electric washing machine driven via power electronic circuit

A power electronic circuit and drive motor technology, applied in the field of washing machines, can solve problems affecting cost, complicated embedding, complex structure and process, etc., and achieve the effects of reducing electromagnetic vibration noise, improving efficiency and torque, and saving electromagnetic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

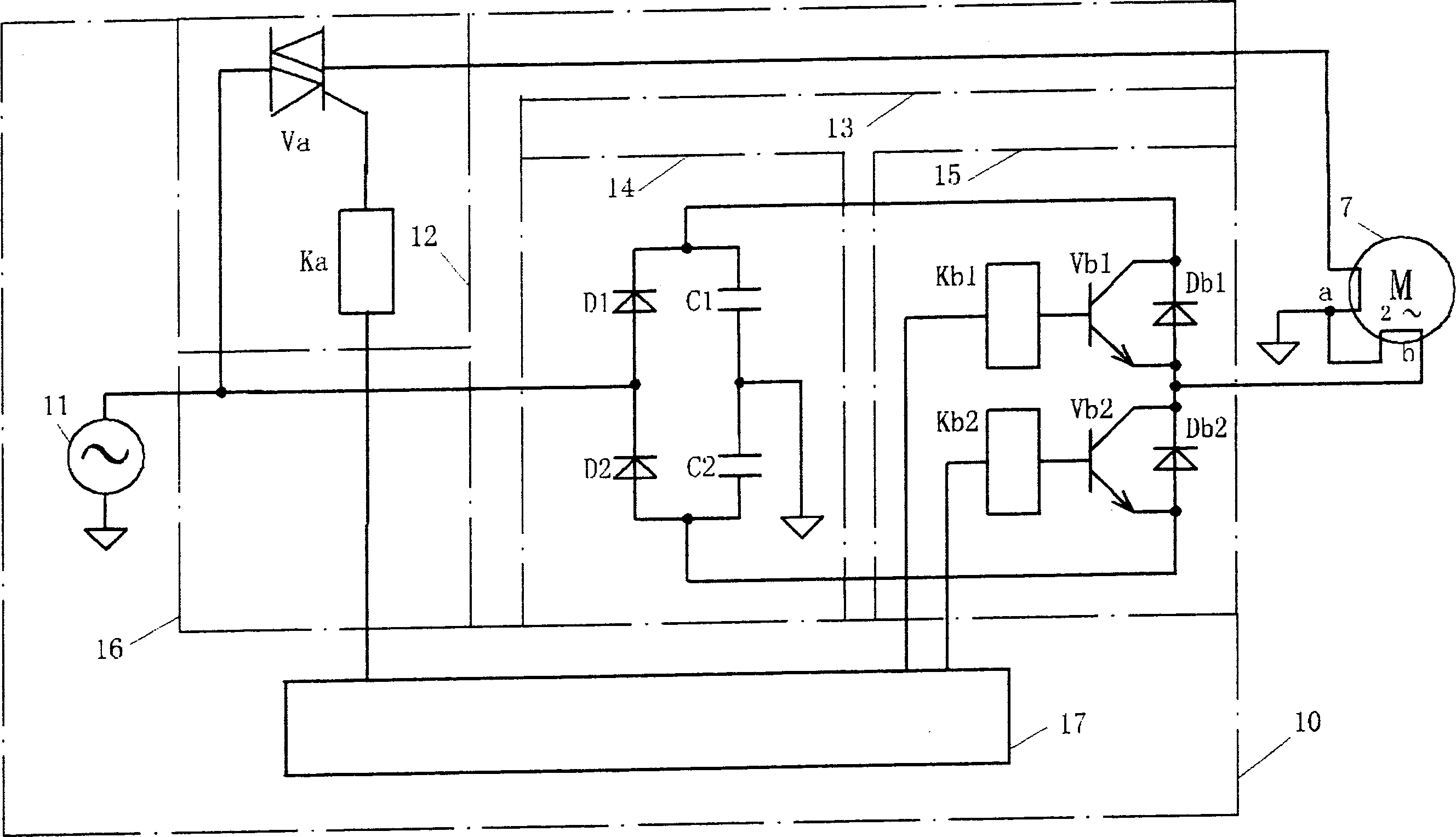

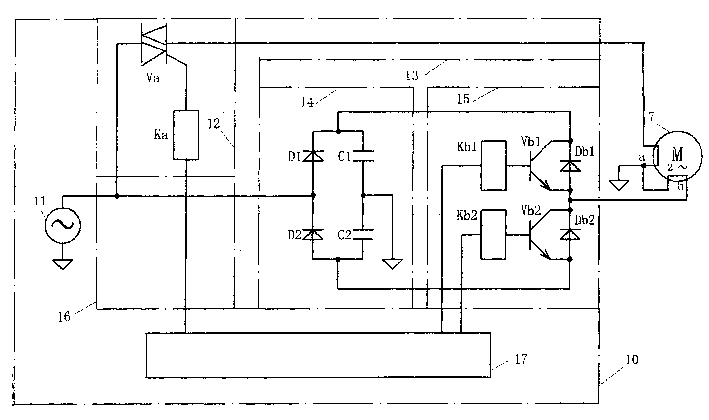

Method used

Image

Examples

Embodiment Construction

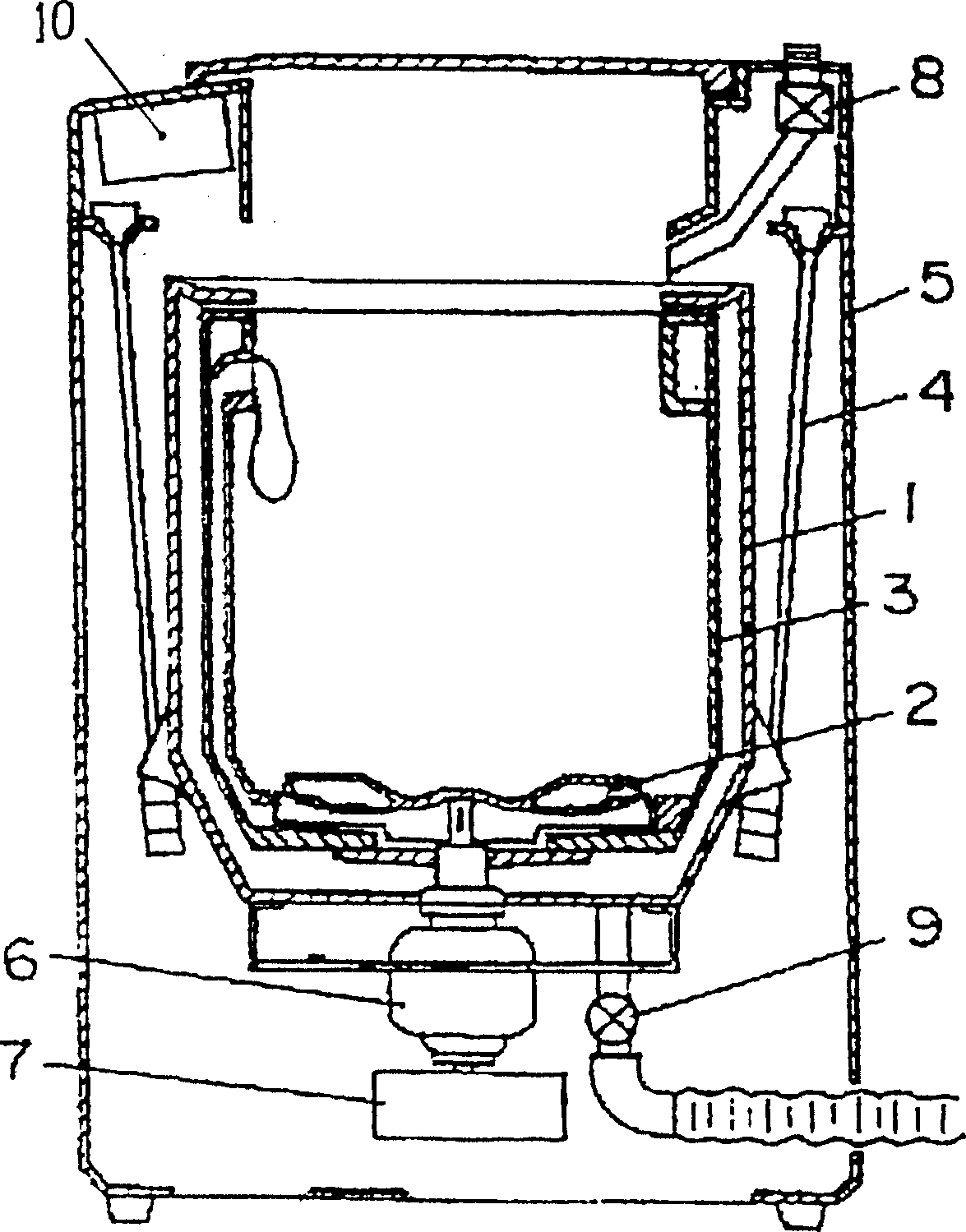

[0022] The embodiment washing machine of the present invention is as figure 2 As shown in , the tub 1 is rotatably provided with a washing tub and dehydration tub 3 rotatably provided with a pulsator 2 at the inner bottom, and is suspended in the main body 5 of the washing machine by the suspension 4 . Speed reducing mechanism 6 is located at the bottom of tub 1, and power is transmitted to pulsator 2 and washing tub and dehydration tub 3 concurrently. A motor 7 is provided at the lower portion of the reduction mechanism 6 . The water supply system 8 supplies water to the washing tub and the dehydration tub 3, and the drain valve system 9 discharges the washing water and the like in the washing and dehydration tub 3. This is a typical composition of a pulsator washing machine. However, it is not limited to the pulsator type washing machine, and may also be an agitator type washing machine or a drum type washing machine. In addition, it is not limited to the structure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com