Ferris wheel rotation car single-loop rotary bearing method

A slewing bearing and Ferris wheel technology, which is applied in the direction of large runner, Russian swing, entertainment, etc., can solve the problems of the Ferris wheel rotation is not stable enough, hidden dangers, the central axis is not on the axis, etc., to achieve stable and reliable slewing motion, guarantee stability and safety, avoid over-constrained effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

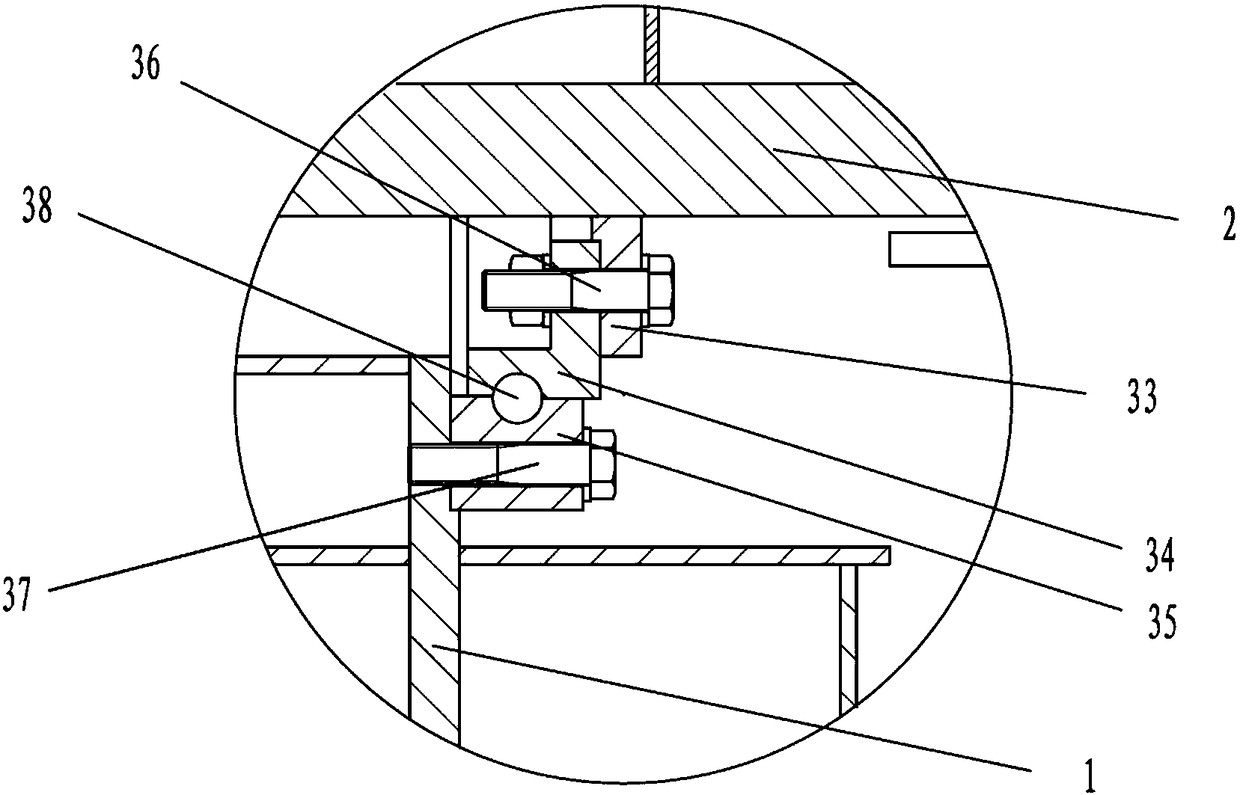

[0024] The specific embodiments are as follows: the lower part of the inner ring of the car has a flange 33 protruding to the outer ring of the car, the inner ring 34 of the single-ring slewing bearing is connected with the flange 33, and the outer ring 35 of the single-ring slewing bearing is connected to the outer ring of the car. Circle 1 is connected together. The inner ring 34 of the single-ring slewing ring and the flange 33 are connected and fixed by bolts 36, the outer ring 35 of the single-ring slewing ring and the outer ring 34 of the car are fixed by the second bolt 37, and the inner ring 34 of the single-ring slewing ring and the single ring Accommodating grooves 38 for accommodating balls are provided between the slewing bearing outer rings 35 .

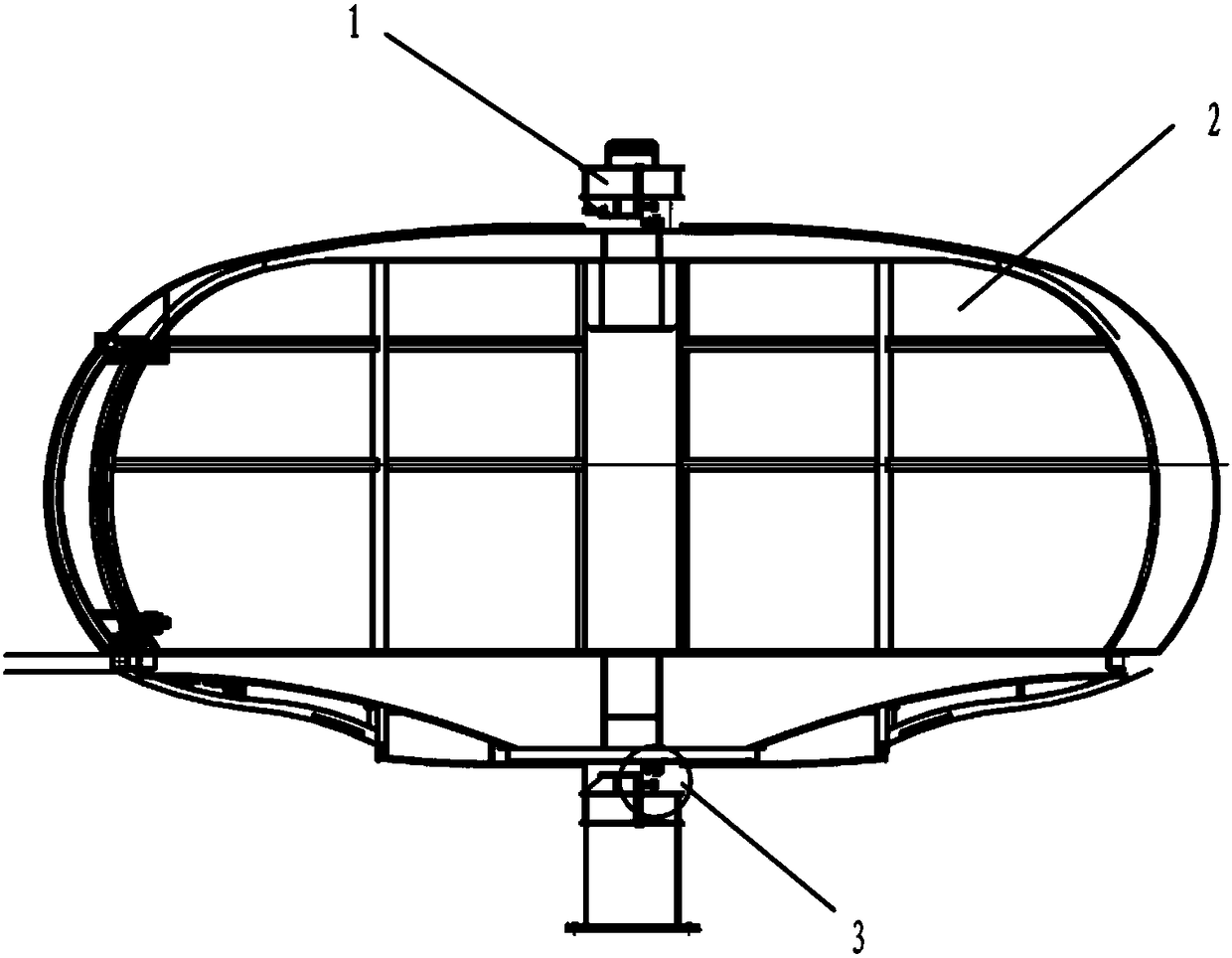

[0025] In actual use, the slewing car is fixed on the outer ring of the circular turntable of the Ferris wheel through the fixing seat, and a plurality of slewing cars are evenly distributed on the outer ring of the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com