End mill

An end mill and blade technology, applied in the field of end mills, can solve the problems of over-constraint, excessive space size constraints, unfavorable blade installation, etc., and achieve the effects of reducing manufacturing difficulty, easily limiting accuracy, and avoiding over-constraint phenomena.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

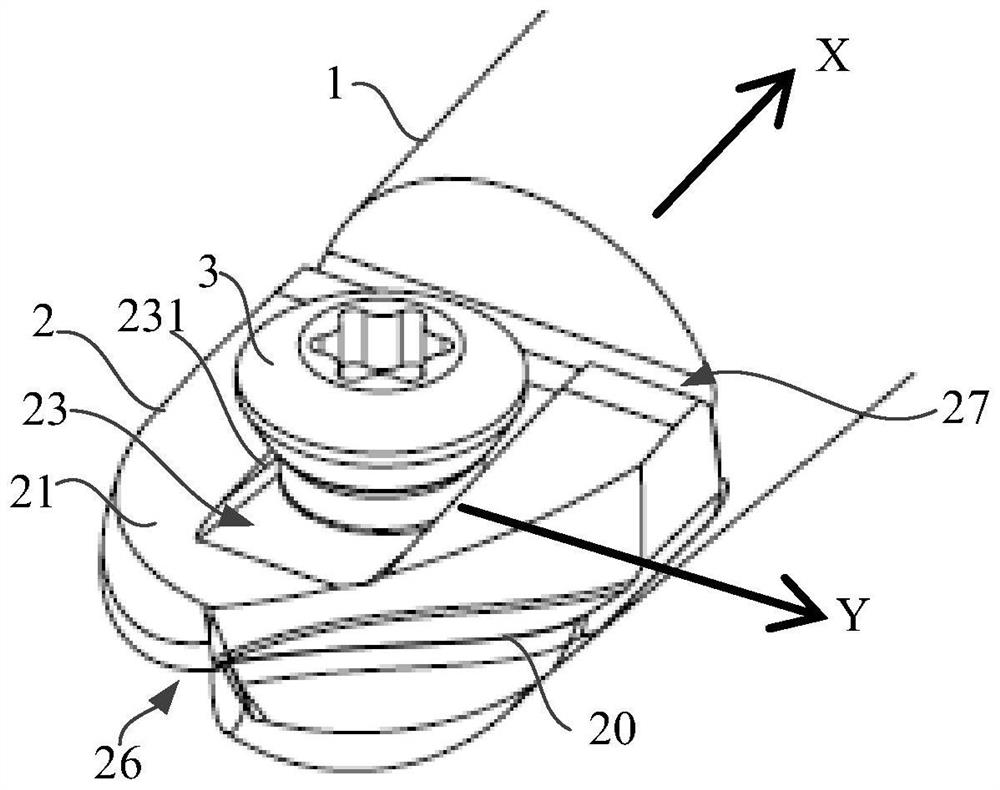

[0042] The present disclosure provides an end mill. End mills can be flat end mills, round nose end mills, etc. The types of end mills are not limited here. Specifically, in this application, end mills are described using ball end mills as an example, and others will not be described in detail. .

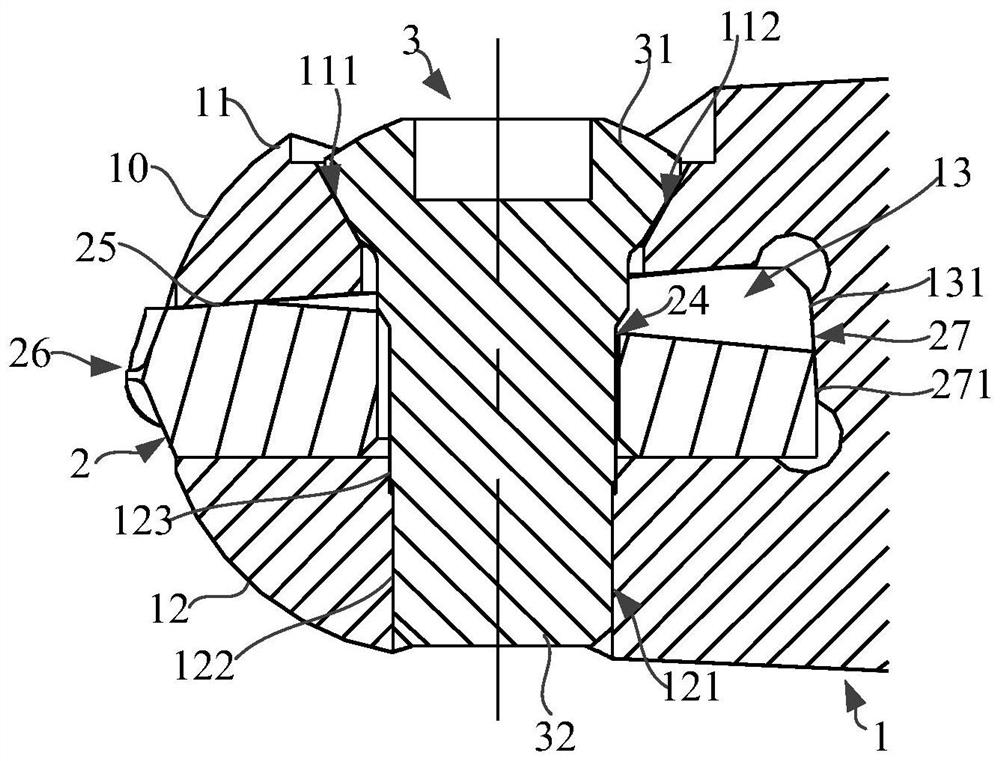

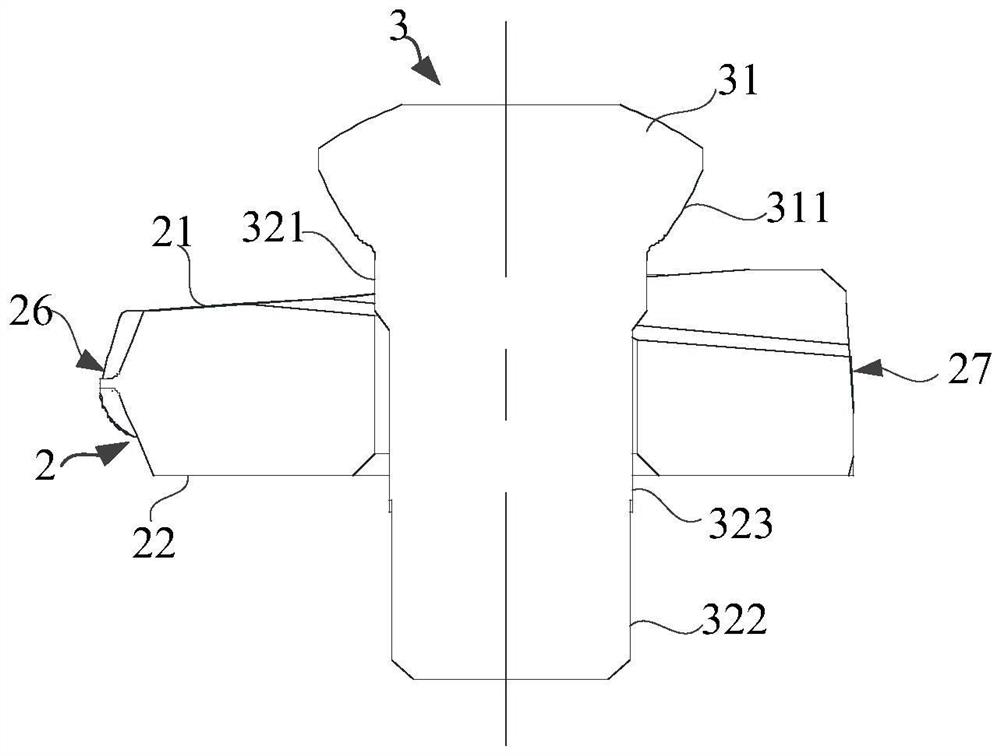

[0043] see figure 1 , The end mill of this embodiment is a rod extending from front to rear along the rotation axis. The rod rotates around its central axis, so the central axis of the rod is the axis of rotation of the end mill. Wherein, the position where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com