A Method for Analyzing Contact Stress of Revolving Pair with Clearance

A contact stress and rotating pair technology, applied in constraint-based CAD, instrument, geometric CAD, etc., can solve problems such as limited number of nodes, system equation constraints, contact boundary stress fluctuations, etc., to avoid over-constrained problems and improve calculation accuracy. , the effect of reducing the fluctuation of contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The present invention will be further described below with reference to the accompanying drawings and specific examples.

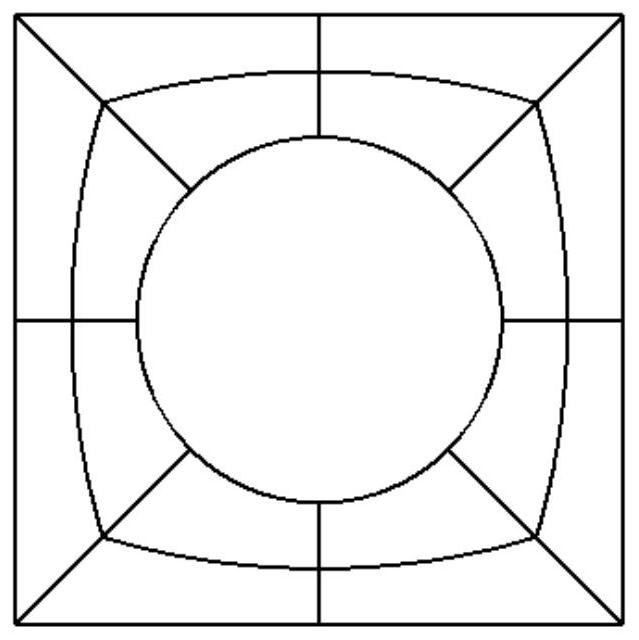

[0050]The present invention is to be set forth is a calculation method for reducing contact stress fluctuations caused by a numerical integral point over-aid finger in a gap rotation sub-contact finite element analysis.

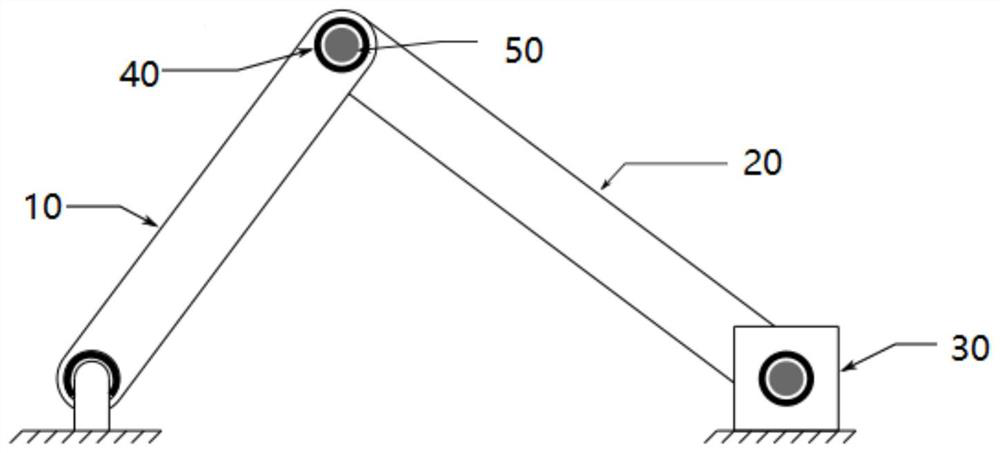

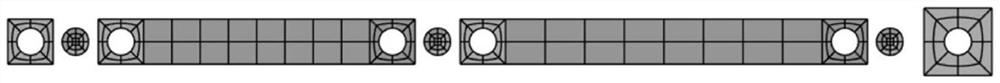

[0051]The crank slider mechanism is extremely common in the mechanical system, such as the piston link mechanism of the engine.figure 1 A schematic diagram of the crank slider mechanism of the present embodiment. The crank slider mechanism includes a crank 10, a link 20, a slider 30, a bearing 40, and a rotating shaft 50. Crank 10 two spin spacing 1.2m, width 0.2m. The connecting rod 20 has two spin spacing 1.6m, and the width is 0.3m. The slider 30 long width is 0.3m. The inner diameter of the bearing 40 is 0.06m. The shaft 50 has a diameter of 0.057 mm. All components have a density of 7800kg / m?3. The elastic modulus of the rotating shaft 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com