Stainless steel strainer machining device

A processing device, stainless steel technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of round waste that cannot be punched, damage to equipment and colander, waste of raw materials, etc., to reduce production costs, and to be safe and convenient to use. , the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

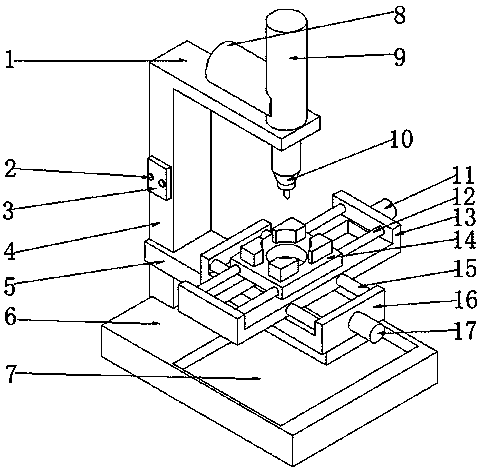

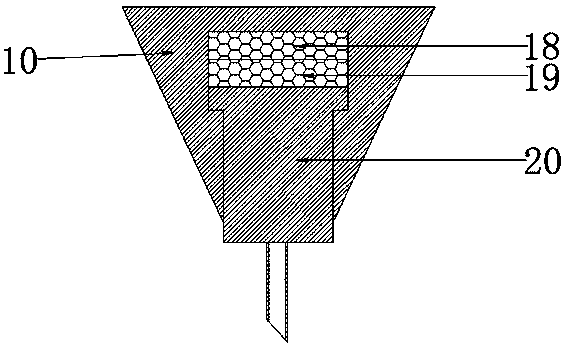

[0017] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a stainless steel colander processing device, comprising a beam 1, a control board 2, an electric control box 3, a column 4, a support frame 5, a base 6, a storage tank 7, a hydraulic pump 8, Hydraulic rod 9, connecting seat 10, first servo motor 11, first threaded rod 12, first moving table 13, working table 14, second threaded rod 15, second moving table 16, second servo motor 17, first The buffer plate 18, the second buffer plate 19 and the punch 20, the top side of the base 6 is provided with a storage tank 7, the other side of the top of the base 6 is provided with a column 4, and one side of the column 4 is provided with a support frame 5, a support frame 5 A second moving table 16 is provided on the top, a second servo motor 17 is provided on one side of the second moving table 16, a second threaded rod 15 is installed on one side of the second servo motor 17 and a first mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com