Chipped ashlar cutting production line

A production line and bar stone technology, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low processing accuracy, and achieve the effects of improving production efficiency, positioning accuracy, and bar stone accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be further clearly described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention:

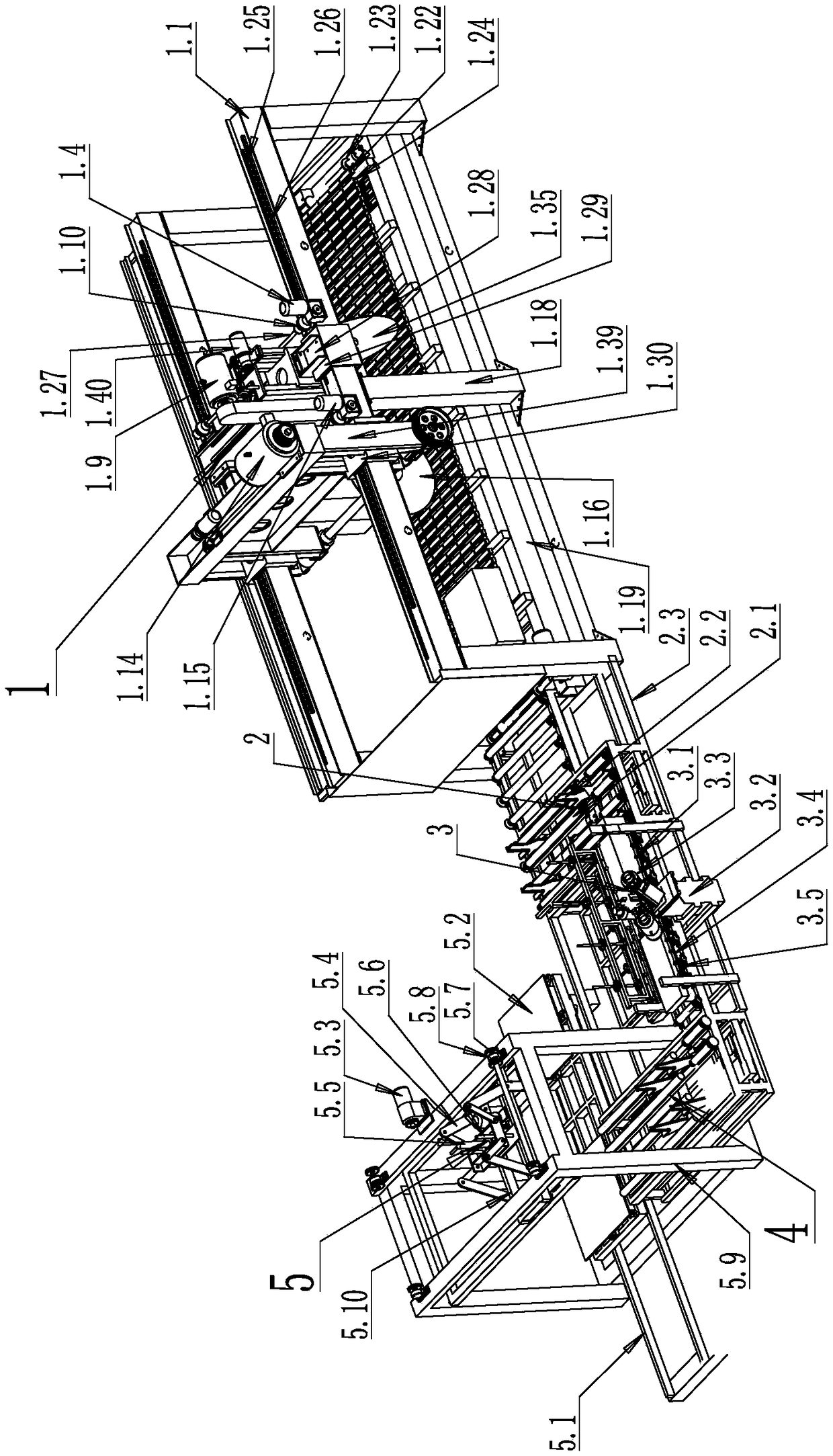

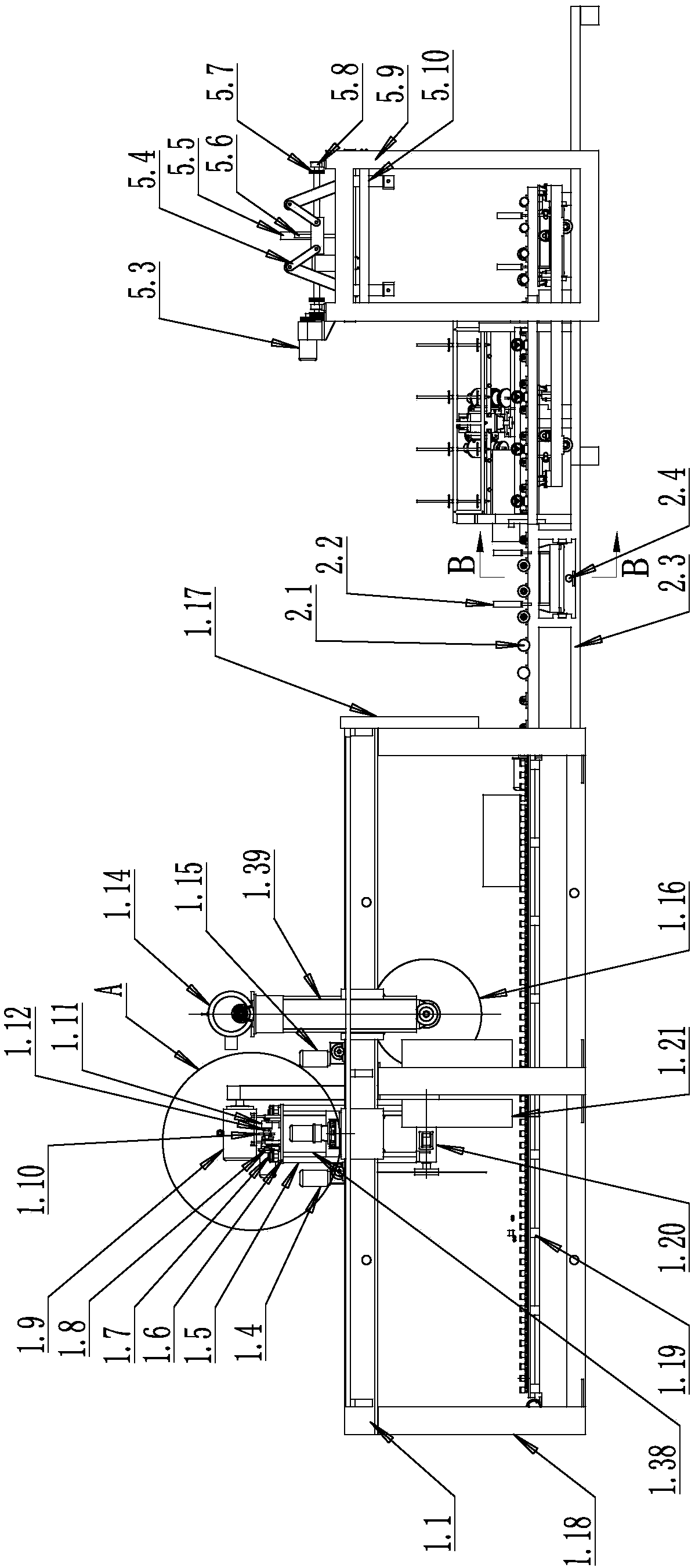

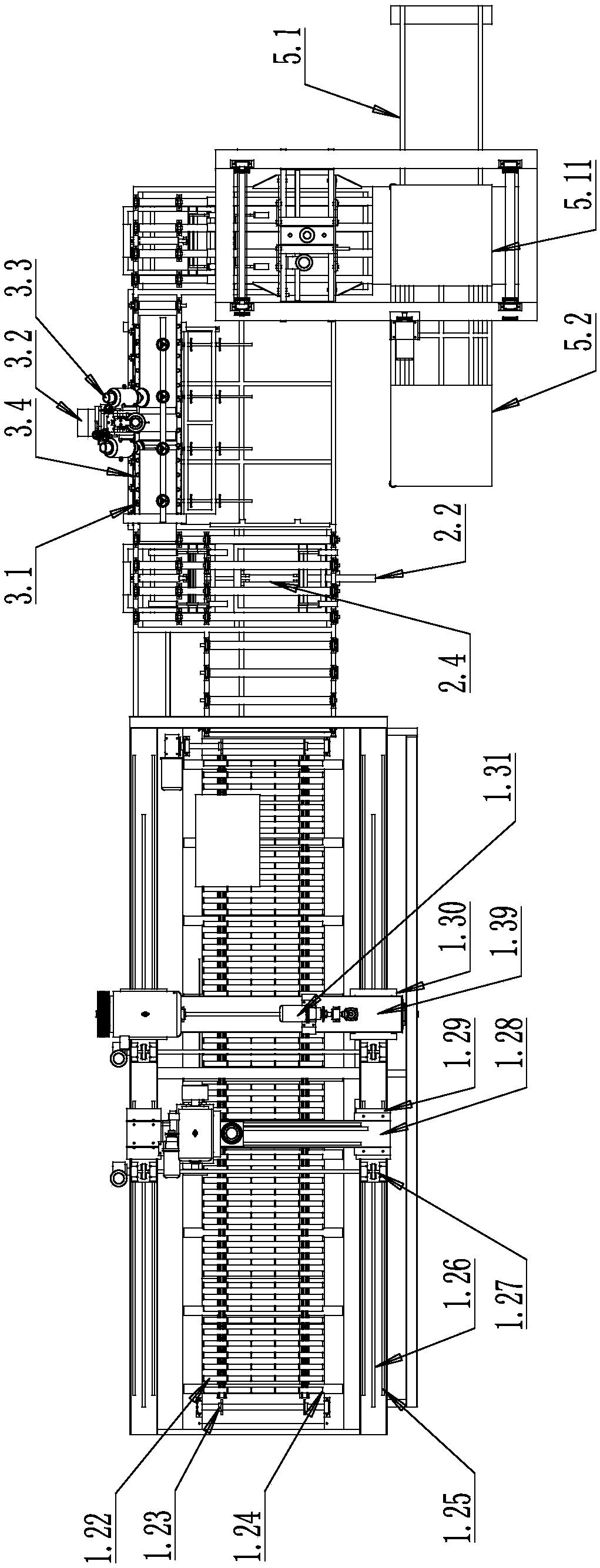

[0038] Such as Figure 1 to Figure 6 As shown, the stone cutting production line according to the present invention includes a sequentially arranged stone cutting device 1, a turning device and a chamfering device 3; the stone cutting device 1 includes an upper beam 1.1, The top of the upper beam 1.1 is provided with a head-to-head cutting device and a piece cutting device, the head-to-head cutting device is connected to the upper beam 1.1 through the head-to-head beam 1.28, and the piece-to-piece cutting device is connected to the upper beam 1.1 through the piece beam 1.39, the head-to-head beam 1.28 and the splitting beam 1.28. A transmission device is provided between the sheet crossbeam 1.39 and the upper beam 1.1; a conveying device is provided at the bottom...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap