Warehouse-out distributing method and warehouse-out distributing device

A distribution method and library distribution technology, applied in the field of communication, can solve the problem of long waiting time for orders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

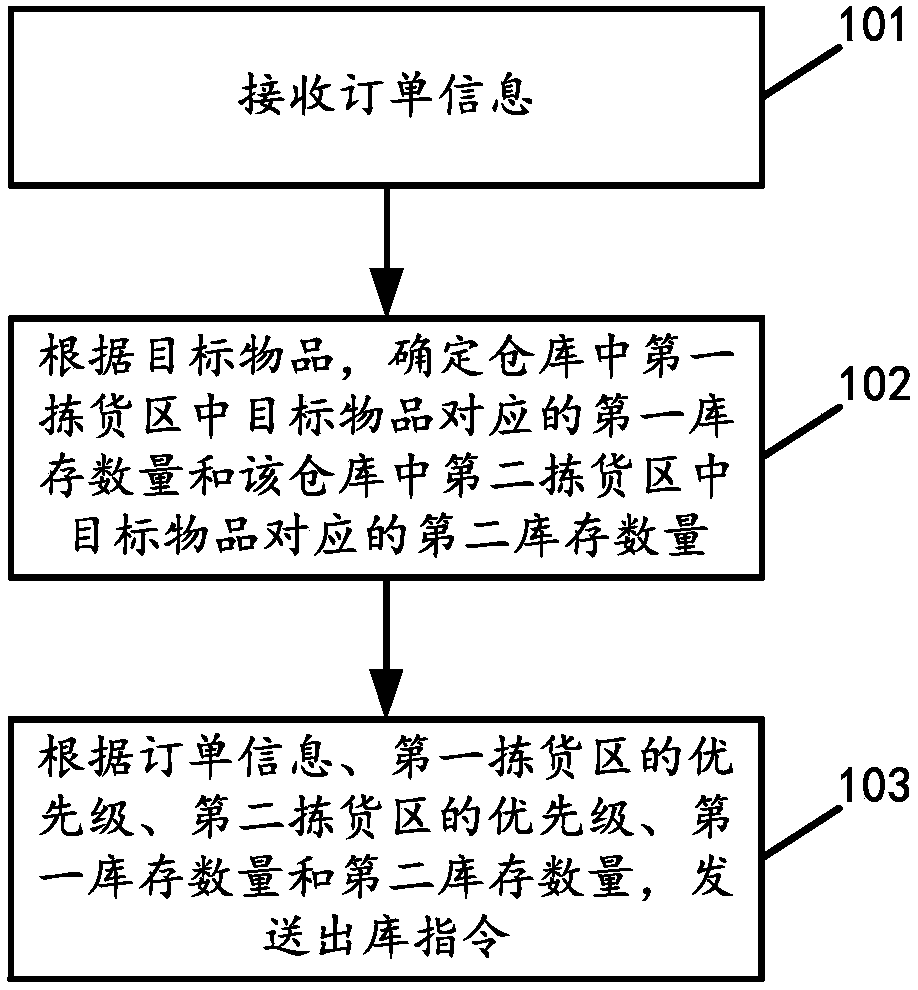

[0043] figure 1 A flow chart of a warehouse-out allocation method provided by an embodiment of the present invention, such as figure 1 As shown, in this method, a warehouse is pre-divided into two picking areas, that is, a warehouse is pre-formed into a first picking area and a second picking area, and the method includes the following steps:

[0044] 101. Receive order information, where the order information includes a target item and the quantity of the target item.

[0045] Specifically, after the customer selects the target item and the corresponding quantity of each target item, the customer settles for the selected target item, and after the customer settles, the corresponding order information can be formed, and the order information includes the customer's selected Target items (such as clothes, shoes, etc.) and the corresponding quantity of each target item, the order information will be received by the outbound distribution device (such as a server), so that the ou...

Embodiment 2

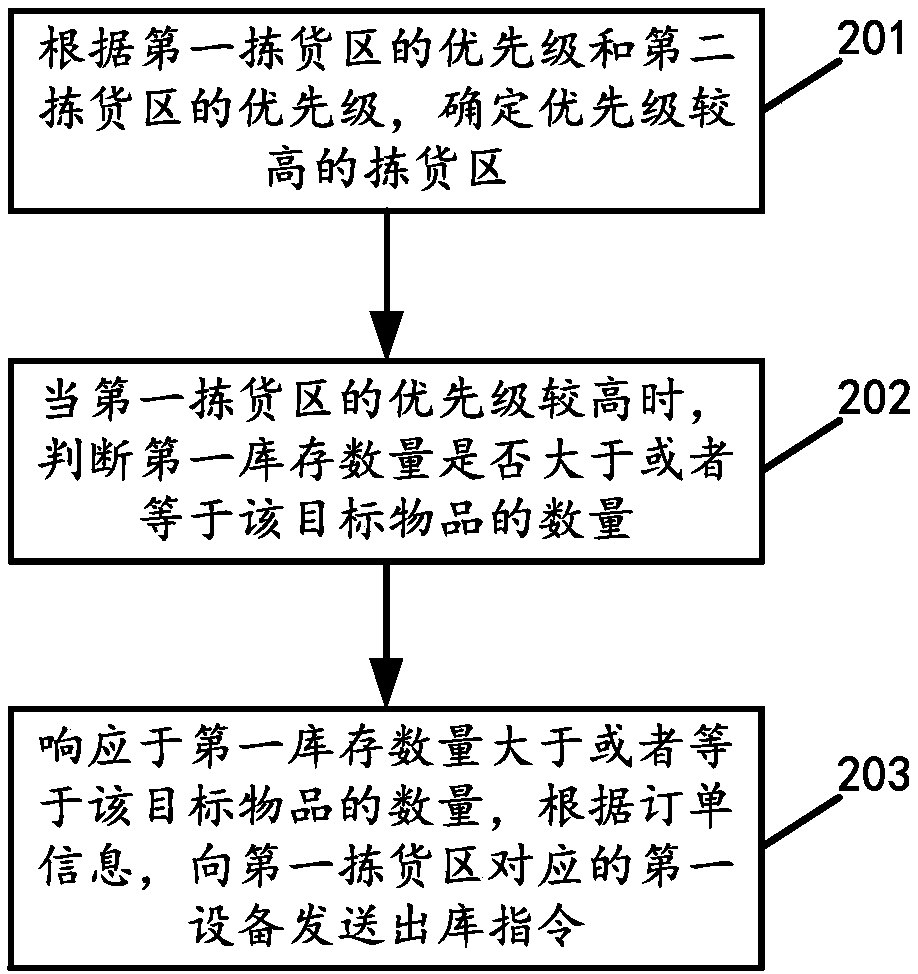

[0056] figure 2 A flow chart of another outbound distribution method provided by the embodiment of the present invention, such as figure 2 As shown, according to the order information, the priority of the first picking area, the priority of the second picking area, the first inventory quantity and the second inventory quantity, when sending the outbound instruction, the following steps are specifically included:

[0057] 201. Determine a picking area with a higher priority according to the priority of the first picking area and the priority of the second picking area.

[0058] The following is an example where the priority of the first picking area is higher than that of the second picking area. It should be noted that the priority of the first picking area is lower than that of the second picking area. In the case of priorities, the order information is processed in a similar manner, which will not be described in detail in the following embodiments.

[0059] 202. When th...

Embodiment 3

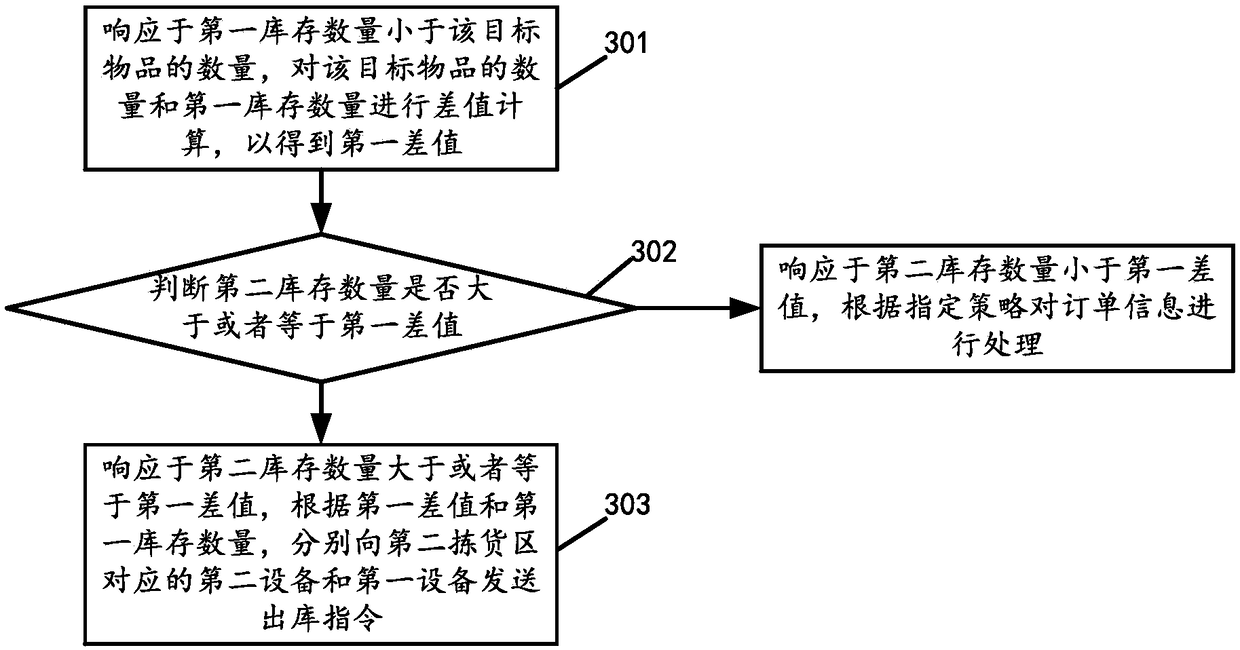

[0064] exist figure 2 On the basis of the corresponding outbound allocation method, the embodiment of the present invention provides a flow chart of another outbound allocation method, as shown in image 3 As shown, the following steps may be included:

[0065] 301. In response to the first inventory quantity being smaller than the quantity of the target item, perform difference calculation between the quantity of the target item and the first inventory quantity to obtain a first difference.

[0066] Specifically, when the first inventory quantity is less than the quantity of the target item, at least two pick-up zones are needed for relay picking at this time to complete the shipment of the order information, so it is necessary to obtain the corresponding quantity of the target item and the first inventory quantity The first difference value represents the quantity of target items that need to be delivered from the second picking area.

[0067] 302. Determine whether the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com