Automatic guided vehicle for intelligent material-handling and handling method thereof

An automatic guided vehicle and intelligent material technology, applied in the direction of lifting devices, etc., can solve the problem that tall objects cannot be handled effectively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

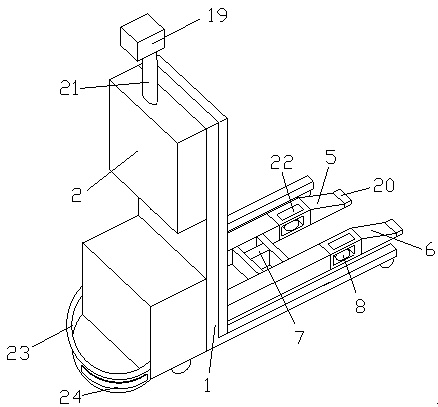

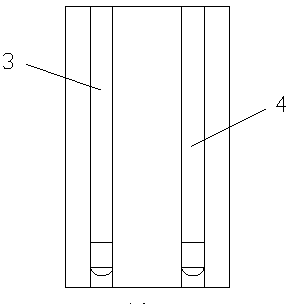

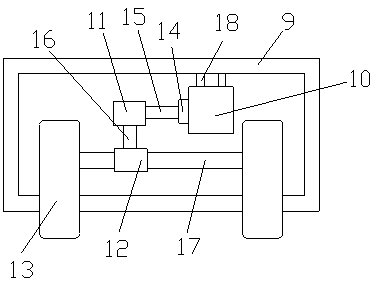

[0029] Such as Figure 1-2 As shown, an automatic guided vehicle for intelligent material handling includes a car body frame 1, and the car body frame 1 is provided with a driving device, a lifting device, a navigation device and a control device for making the driving device walk along a fixed route 2. The lifting device is bolted to the vehicle body frame 1. The lifting device includes a first electric guide rail 3 and a second electric guide rail 4. The first electric guide rail 3 and the second electric guide rail 4 are respectively provided with Corresponding first transport fork 5 and second transport fork 6 on each, a connecting frame 7 is arranged between the first transporting fork 5 and the second transporting fork 6, and the connecting frame 7 is in the shape of an I type setting, the first transport fork 5 and the second transport fork 6 are fixedly connected to the connecting frame 7, and the sliders on the first electric guide rail 3 and the second electric guide...

Embodiment 2

[0032] Such as Figure 1-3 As shown, an automatic guided vehicle for intelligent material handling includes a car body frame 1, and the car body frame 1 is provided with a driving device, a lifting device, a navigation device and a control device for making the driving device walk along a fixed route 2. The lifting device is bolted to the vehicle body frame 1. The lifting device includes a first electric guide rail 3 and a second electric guide rail 4. The first electric guide rail 3 and the second electric guide rail 4 are respectively provided with Corresponding first transport fork 5 and second transport fork 6 on each, a connecting frame 7 is arranged between the first transporting fork 5 and the second transporting fork 6, and the connecting frame 7 is in the shape of an I type setting, the first transport fork 5 and the second transport fork 6 are fixedly connected to the connecting frame 7, and the sliders on the first electric guide rail 3 and the second electric guide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap