A comprehensive treatment method for salt mother liquor and salt mud

A comprehensive treatment and mother liquor technology, which is applied in the field of salt production, can solve the problems of high cost of magnesium removal by sodium hydroxide, high failure rate of filter press equipment, high cost of dry basis treatment, etc. Filtration system, the effect of reducing the cost of magnesium removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

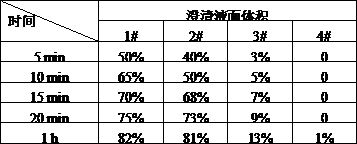

Image

Examples

Embodiment 1

[0038] Example 1 Experimental Verification

[0039] 1. Working principle and preparation before experiment

[0040] (1) MgCl 2 , Fe, Mn treatment method

[0041] MgCl removal by lime (main component CaO) method 2 , the chemical reaction formula is:

[0042] CaO + H 2 O = Ca(OH) 2 exothermic reaction of digestion

[0043] MgCl 2 + Ca(OH) 2 = Mg(OH) 2 ↓ + CaCl 2 (newborn)

[0044] According to literature search, in order to achieve the purpose of removing magnesium, the pH of the solution must be ≥ 11.3. The actual amount of raw halogen used in production is 530m 3 / h or so, the amount of salt-making mother liquor produced is 70m 3 / h, the amount of salt mother liquor is about 13% of the original brine amount. Detection of MgCl in the original halogen before the experiment 2 The content is about 1.6g / l, and the evaporation enrichment content increases after entering the salt evaporation tank, which is about 2 ten times the content.

[0045] (2) Treatment method ...

Embodiment 2

[0125] Example 2 Industrialized operation

[0126] 1. Operation of lime and magnesium removal

[0127] According to the conclusion of the laboratory simulation experiment, the magnesium removal agent uses lime with a particle size of 30-100 mesh and a purity greater than 70%; firstly, the mother liquor of salt making is pumped into the mother liquor stirring reaction tank through the mother liquor transfer pump, and the magnesium chloride content in the mother liquor is obtained through analysis According to the stoichiometric relationship, an excess of 50% lime is added. The lime is first emulsified by the emulsification tank for 30 minutes, and then pumped into the mother liquor stirring reaction tank through the emulsification pump, and the stirring is started to fully react. After 4 hours, it was detected that magnesium ions were not detected in the slurry in the stirring reaction tank, and the pH was greater than 11.4, and then the treated mother liquor delivery pump was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com