A prediction model for the yield of coking products

A prediction model and technology of tar yield, applied in the coking industry, can solve problems such as large deviation and inaccurate prediction results, and achieve scientific prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The experimental furnace type is 7.63m, the coking time is 25 hours, and the dry basis volatile matter V d is 22.05, the coal caking index G is 78.1, and the active component E is 70.

[0072] In actual production, the yield of tar is 2.56, the yield of crude benzene is 0.70, and the yield of net gas is 309.5.

[0073] Calculate the yield through the chemical product yield prediction model:

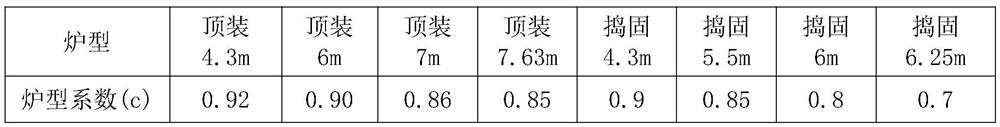

[0074] Comparing with Table 1, the influence coefficient of furnace type and coking time on tar oil yield can be obtained from a=c*d

[0075] a=0.85*0.8=0.68

[0076] Comparing with Table 2, from b=0.95*c, the influence coefficient of furnace type on crude benzene yield

[0077] b=0.95*0.85=0.8075

[0078] Calculate tar yield (%): = 0.68*[0.18*V d *(G+0.25*E)+0.8] / 100

[0079] =0.68*[0.18*22.05*(78.1+0.25*70)+0.8] / 100

[0080] =2.58

[0081] Calculate crude benzene yield (%) = 0.8075*[0.043*V d *(G+0.18*E)+0.6] / 100

[0082] =0.8075*[0.043*22.05*(G+0.18*70)+0.6] / 100

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com