Vertical and multilayer automatic LiuPao tea fermenting device

A technology of automatic fermentation and Liubao tea, applied in biochemical cleaning equipment, enzymology/microbiology equipment, bioreactor/fermentation tank combination, etc., can solve problems such as management confusion, indistinguishable tea leaves, and poor results. Achieve the effects of saving production plant land, preventing tea accumulation and clogging, and cleaning and sanitation during the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

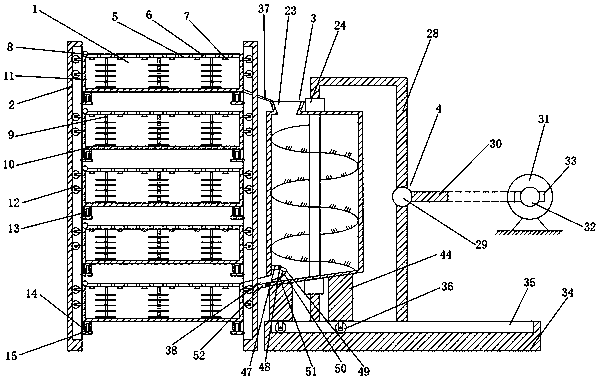

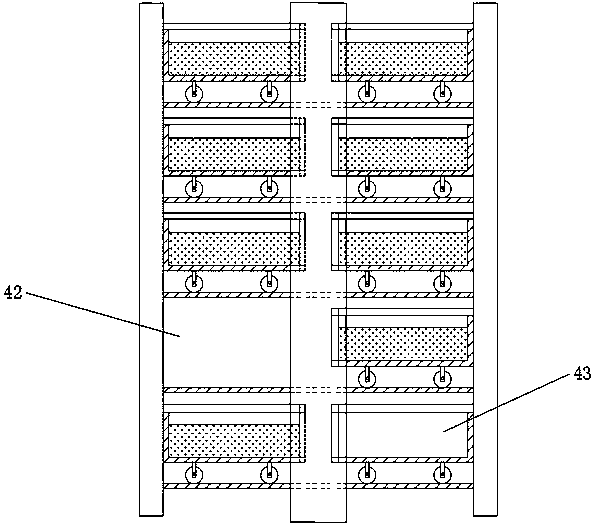

[0031] As shown in the accompanying drawings of the description, a vertical multi-layer Liubao tea automatic fermentation device includes a fermentation box 1, a support frame 2, a multifunctional turning tank 3, a turning mechanism 4 and a control system; the support frame 2 is mainly composed of It is composed of six straight bars parallel to each other and erected on the ground; the fermentation tank 1 is divided into two rows and arranged side by side on the support frame 2; the fermentation tank 1 includes a top cover 5, a ventilation hole 6, and a nozzle 7 , Hinge I8, stirring vertical bar 9, stirring bar 10, fermentation chamber 11, vertical guide wheel 12, horizontal guide wheel 13, guide plate 14, hinge II 15, vertical track 16, horizontal track 17, vertical guide wheel Avoidance hole 18, synchronous motor 19, drum 20, synchronous belt 21 and tea outlet door 22; the short side of the top cover 5 is movably connected with the short side of the fermentation chamber 11 th...

Embodiment 2

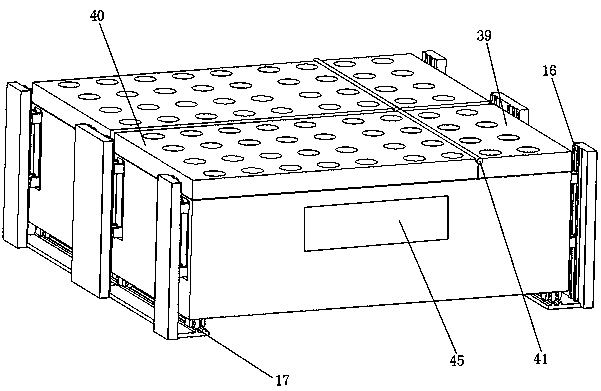

[0035]A vertical multi-layer Liubao tea automatic fermentation device, comprising a fermentation box 1, a support frame 2, a multifunctional turning tank 3, a turning mechanism 4 and a control system; the support frame 2 is mainly composed of six parallel and upright sets on the ground The above-mentioned straight bar is formed; the fermentation box 1 is divided into two rows, and arranged side by side on the support frame 2; Rod 9, mixing bar 10, fermentation chamber 11, vertical guide wheel 12, horizontal guide wheel 13, guide plate 14, hinge II 15, vertical track 16, horizontal track 17, vertical guide wheel escape hole 18, synchronous motor 19 , drum 20, timing belt 21 and tea outlet 22; the short side of the top cover 5 is movably connected with the short side of the fermentation chamber 11 through the hinge I8; the top cover 5 includes a front cover 39, a rear cover 40 and a hinge Page III41; the front cover 39 is movably connected with the rear cover 40 through the hing...

Embodiment 3

[0039] A vertical multi-layer Liubao tea automatic fermentation device, comprising a fermentation box 1, a support frame 2, a multifunctional turning tank 3, a turning mechanism 4 and a control system; the support frame 2 is mainly composed of six parallel and upright sets on the ground The above-mentioned straight bar is formed; the fermentation box 1 is divided into two rows, and arranged side by side on the support frame 2; Rod 9, mixing bar 10, fermentation chamber 11, vertical guide wheel 12, horizontal guide wheel 13, guide plate 14, hinge II 15, vertical track 16, horizontal track 17, vertical guide wheel escape hole 18, synchronous motor 19 , drum 20, timing belt 21 and tea outlet 22; the short side of the top cover 5 is movably connected with the short side of the fermentation chamber 11 through the hinge I8; the top cover 5 includes a front cover 39, a rear cover 40 and a hinge Page III41; the front cover 39 is movably connected with the rear cover 40 through the hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com