A kind of high-performance elastic-plastic damping steel and its manufacturing method and application

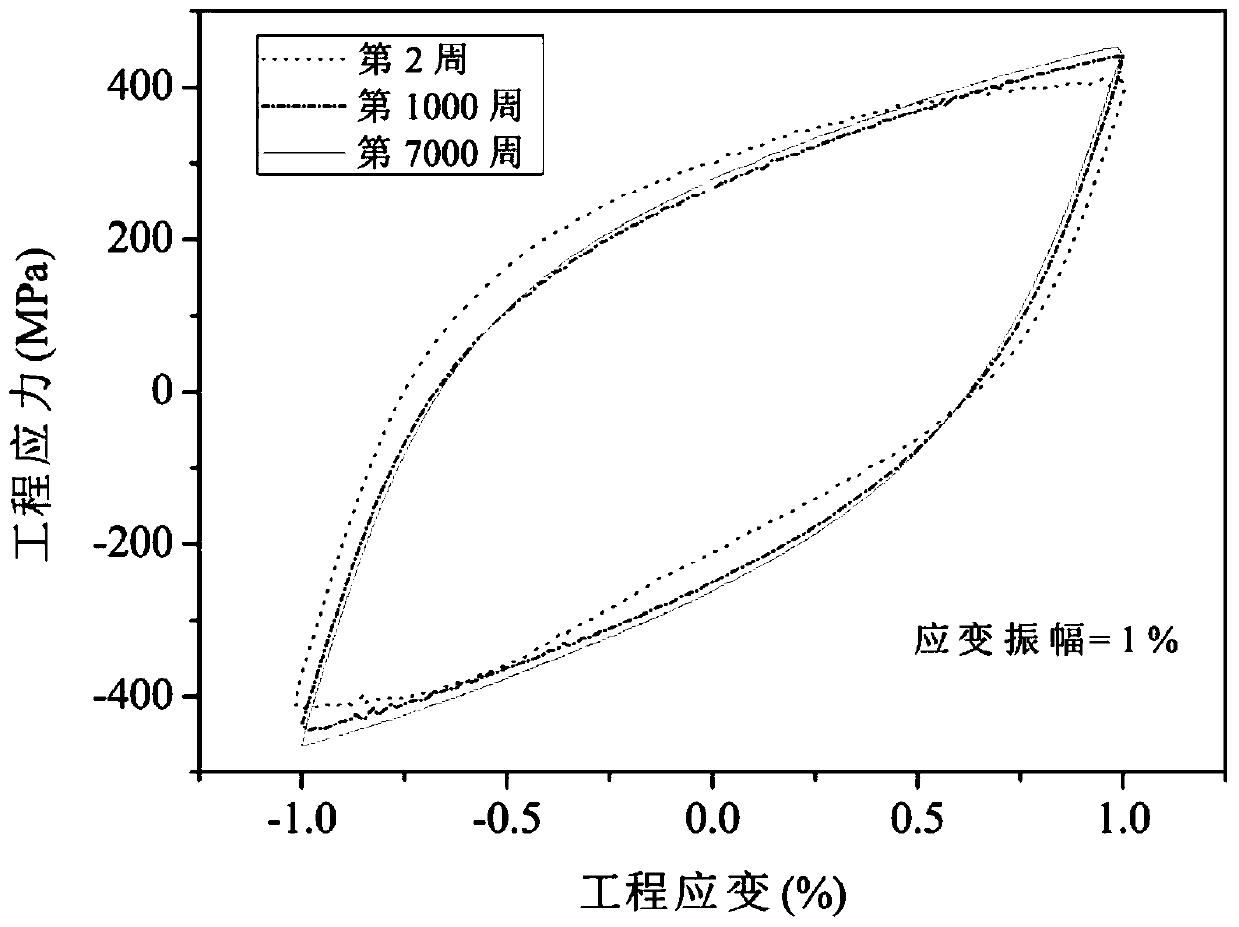

An elastic-plastic, damping steel technology, applied in the field of steel materials, can solve the problem of low fatigue life and achieve the effect of low yield strength and excellent low-cycle fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of the first described high-performance elastic-plastic damping steel comprises the following steps:

[0066] 1) Smelting and casting according to the following composition ratios to obtain cast slabs

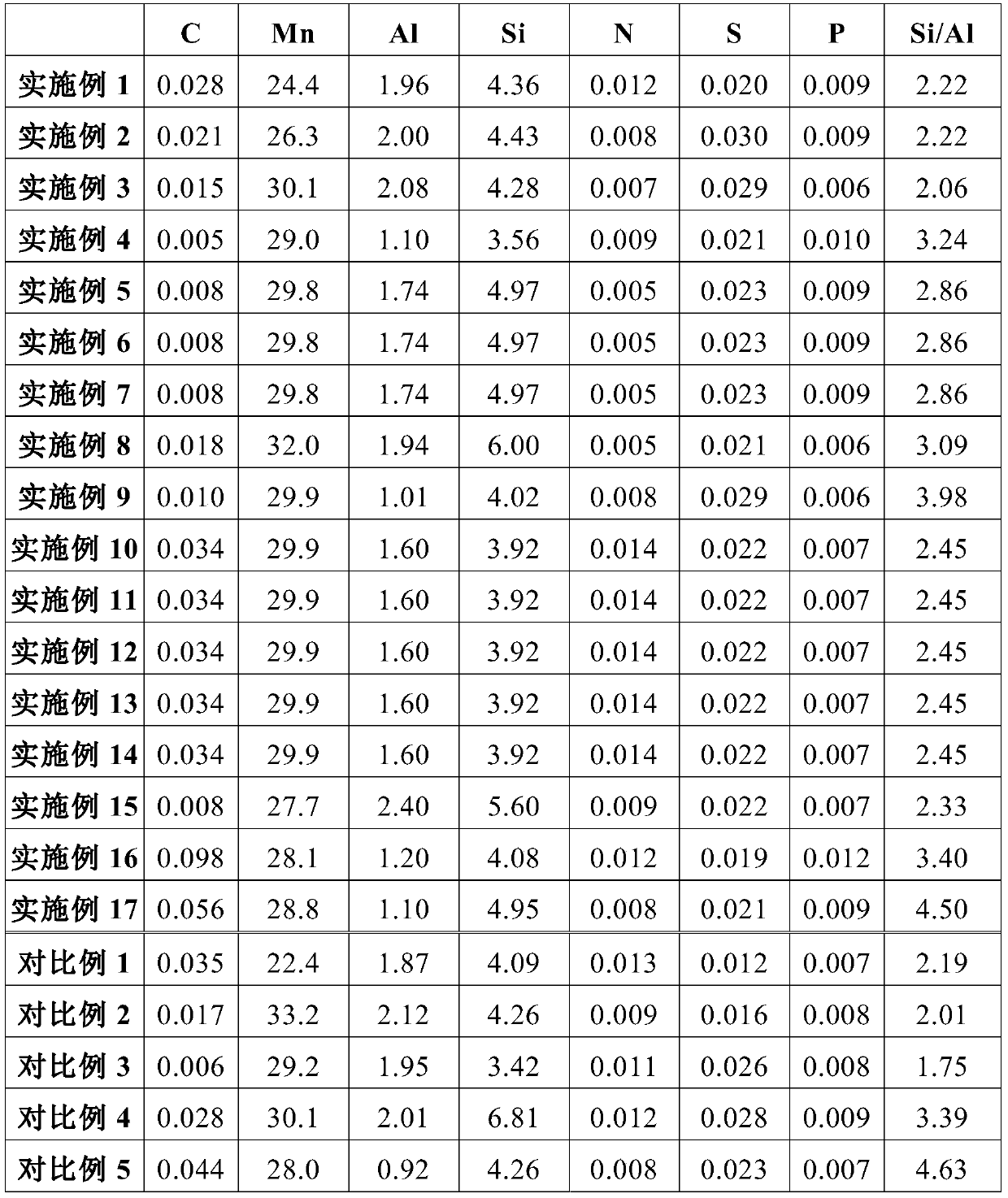

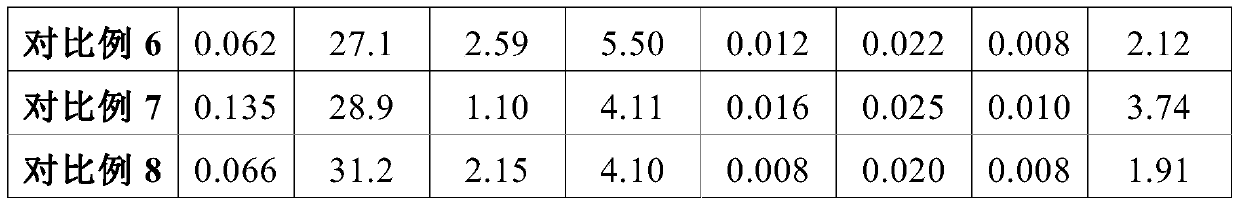

[0067] The mass percentage of chemical composition is: 24%≤Mn≤32%, 3.5%≤Si≤6.0%, 1.0%

[0068] 2) Hot rolling

[0069] Heating the billet at 1000-1250°C for a holding time of 0.5-3 hours, hot-rolling the billet into a hot-rolled plate, hot-rolling deformation ≥ 25%, and final rolling temperature ≥ 800°C;

[0070] 3) Annealing after hot rolling

[0071] Heating the hot-rolled sheet to a soaking temperature of 700-1100° C. for a soaking time of 0.5-10 hours; cooling the steel sheet to room temperature after annealing.

[0072] The preparation method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com