High-carbon-content and easily-cut steel for engineering machinery and production method thereof

A construction machinery and free-cutting technology, applied in the field of alloy steel materials, can solve the problems of large loss of abrasive tools, inability to meet cutting requirements, difficult machining accuracy, etc., to reduce machining loss, improve yield, production efficiency, and machining performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the above-mentioned high-carbon free-cutting engineering machinery steel comprises the following steps: (a) carrying out converter steelmaking with molten iron and steel scrap as raw materials to obtain molten steel; the tapping temperature of the molten steel is 1620-1680°C, and the molten steel Add 1 to 2 kg of ferrosilicon, 3 to 5 kg of lime, 7 to 8 kg of silicon manganese and 5 to 7 kg of low-nitrogen recarburizer to each ton of molten steel during tapping, and control the mass percentage content of C in the molten steel to 0.10 to 0.40 %, the mass percentage content of P is 0.001-0.020% and the mass percentage content of S is 0.005-0.030%; (b) performing LF refining on the molten steel, and the LF refining includes using auxiliary materials to make white slag to deoxidize the molten steel , the amount of the auxiliary materials added is 1-3kg of lime and 0.5-2.0kg of calcium carbide particles per ton of molten steel; the temperature of the ...

Embodiment 1- Embodiment 3、 comparative example 1

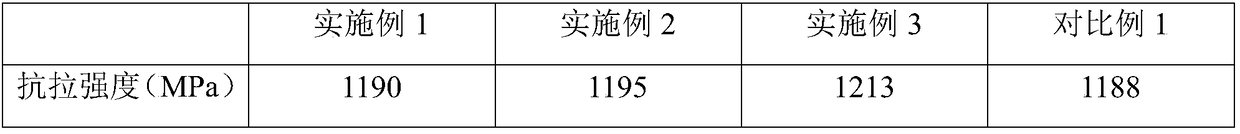

[0018] Embodiment 1-Example 3 and Comparative Example 1 provide a kind of high-carbon free-cutting engineering machinery steel respectively, and its chemical composition is as shown in Table 1:

[0019] Table 1 Chemical composition table of high-carbon free-cutting engineering machinery steel in Example 1-Example 3 and Comparative Example 1

[0020] Content (wt%)

Example 1

Example 2

Example 3

Comparative example 1

C

0.78

0.80

0.82

0.80

Si

0.20

0.19

0.19

0.19

mn

0.64

0.65

0.63

0.67

P

0.009

0.010

0.013

0.018

S

0.029

0.023

0.028

0.003

[0021] The above-mentioned high-carbon free-cutting construction machinery steel is prepared by the following method, which specifically includes the following steps:

[0022] (a) Carry out converter steelmaking with molten iron and steel scrap as raw materials to obtain molten steel; the tapping temperature of the molten steel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap