Ultrasonic sclerometer

A hardness tester and ultrasonic technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc. The effect of reducing design cost and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

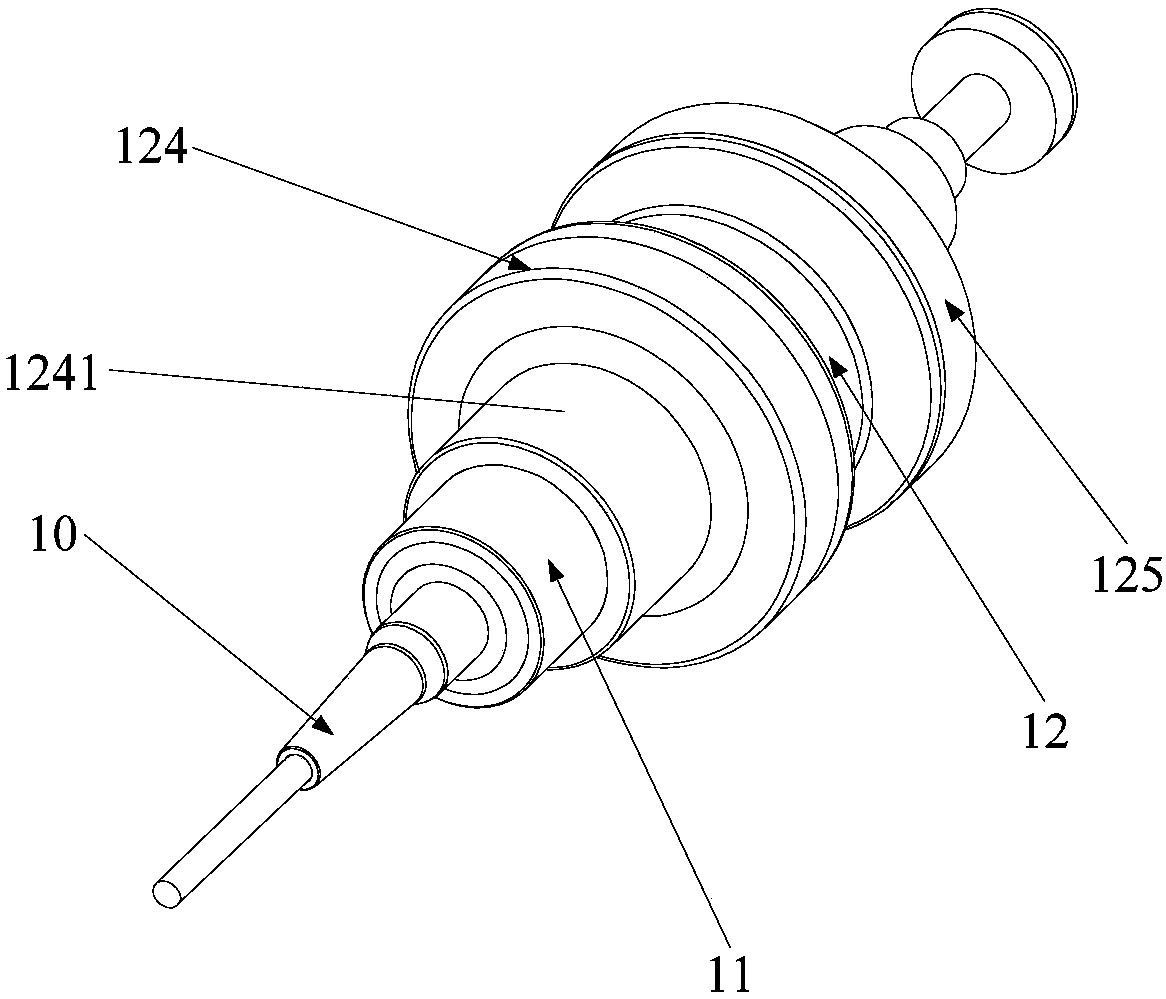

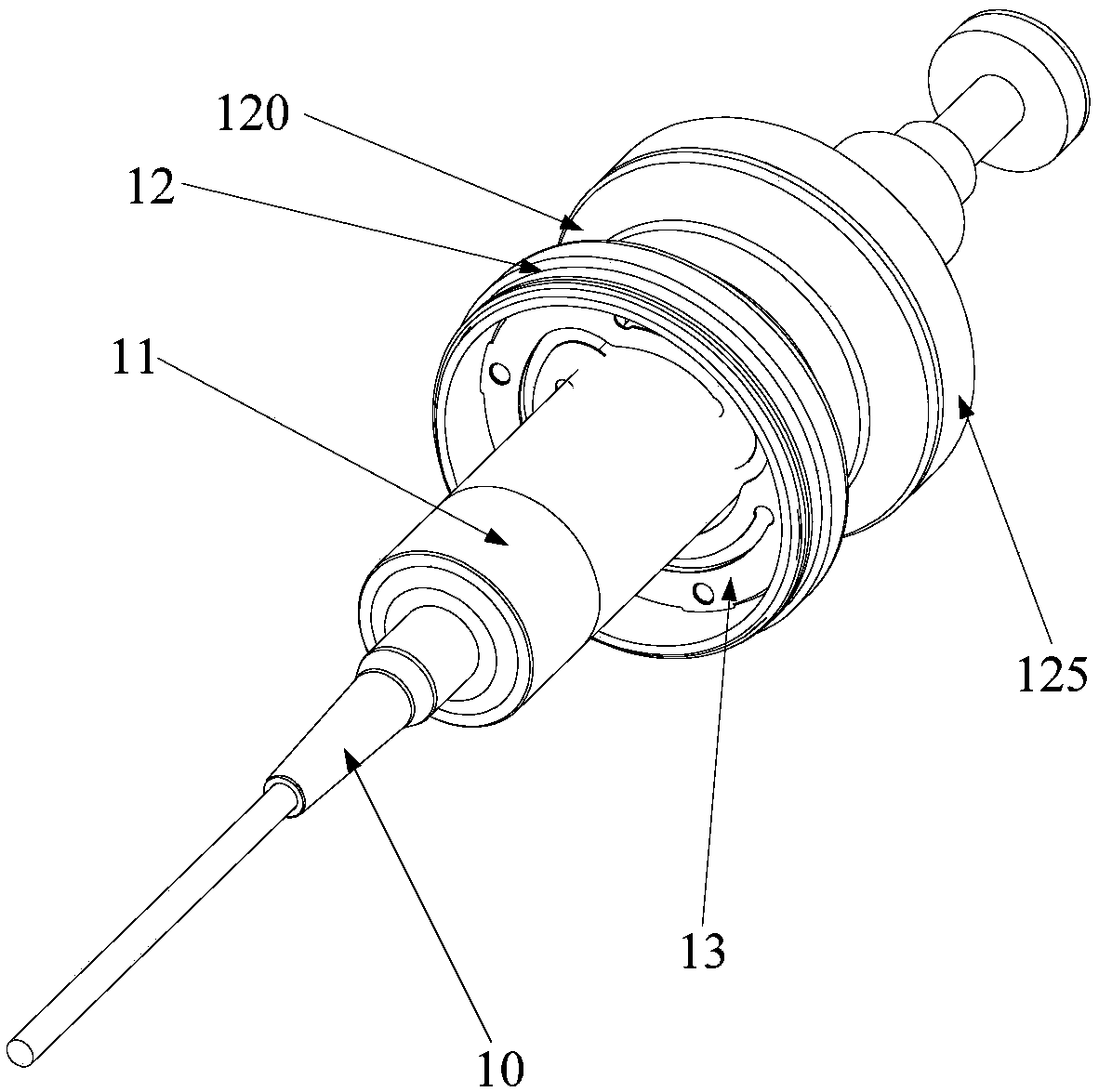

[0023] see Figure 1-6 , the ultrasonic hardness tester includes a probe rod 10 , a hardness tester main body 11 , a fixing sleeve 12 , a first metal support piece 13 and a second metal support piece 14 .

[0024] The hardness tester main body 11 has a cylindrical shape.

[0025] The detection rod 10 is cylindrical, wherein the detection rod 10 is telescopically arranged on one side of the main body 11 of the hardness tester. It should be understood that the connection structure between the probe rod 10 and the hardness tester main body 11 is a prior art, and will not be repeated here.

[0026] The fixed sleeve 12 is cylindrical, and the main body 11 of the durometer is telescopically arranged in the fixed sleeve 12 . In this embodiment, the outer wall of the fixing sleeve 12 is provided with an annular locking groove 120 , which can be held in the annular locking groove 120 to increase the grip strength.

[0027] In this embodiment, the fixing sleeve 12 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com