Assembled cable support capable of being bidirectionally adjusted

A cable support, two-way adjustment technology, applied in cable installation, ground cable installation and other directions, can solve the problems of insufficiency, long construction time, difficult to adjust the spacing of the support arms, etc., to achieve fast and convenient installation, avoid welding construction, guarantee The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

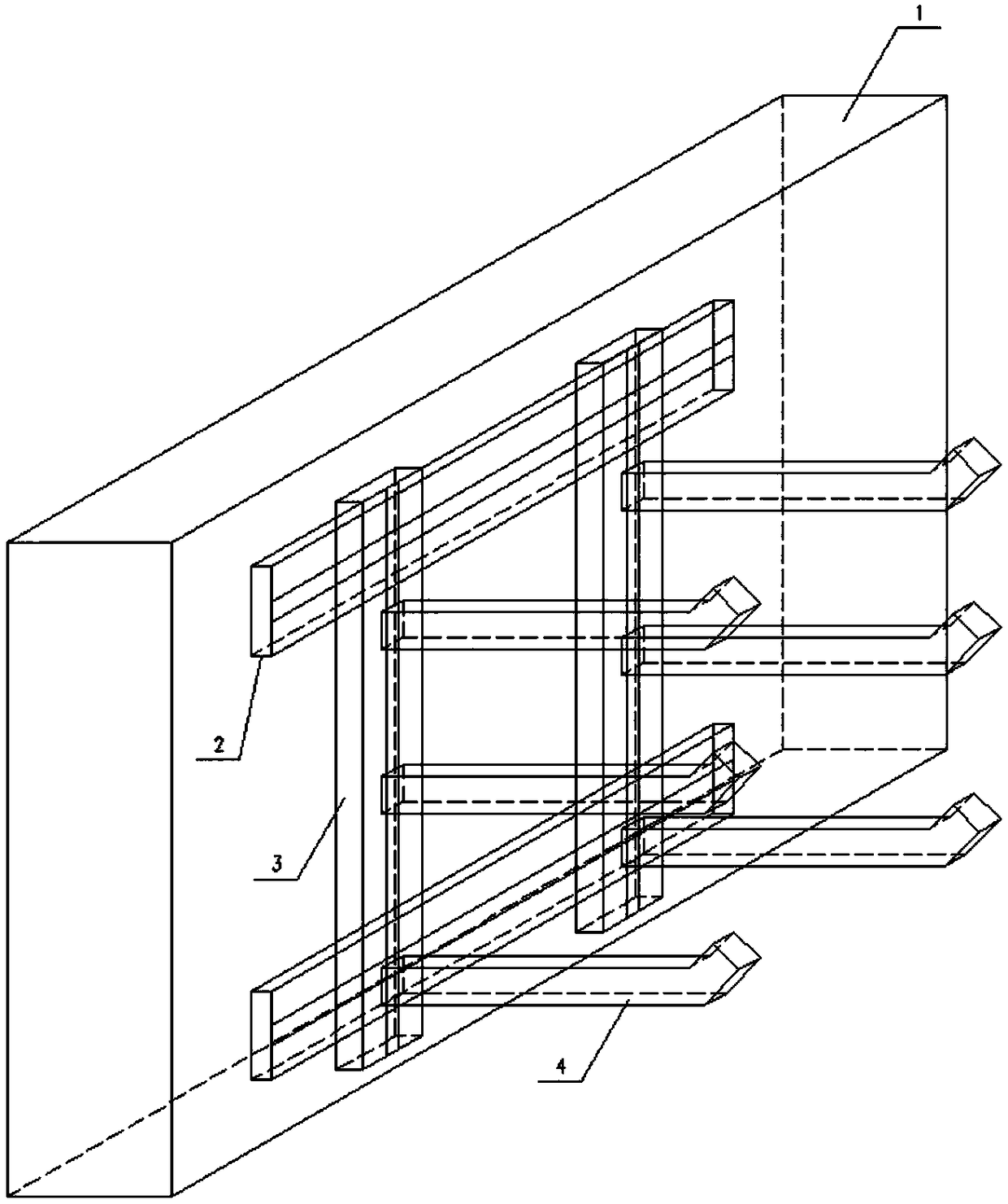

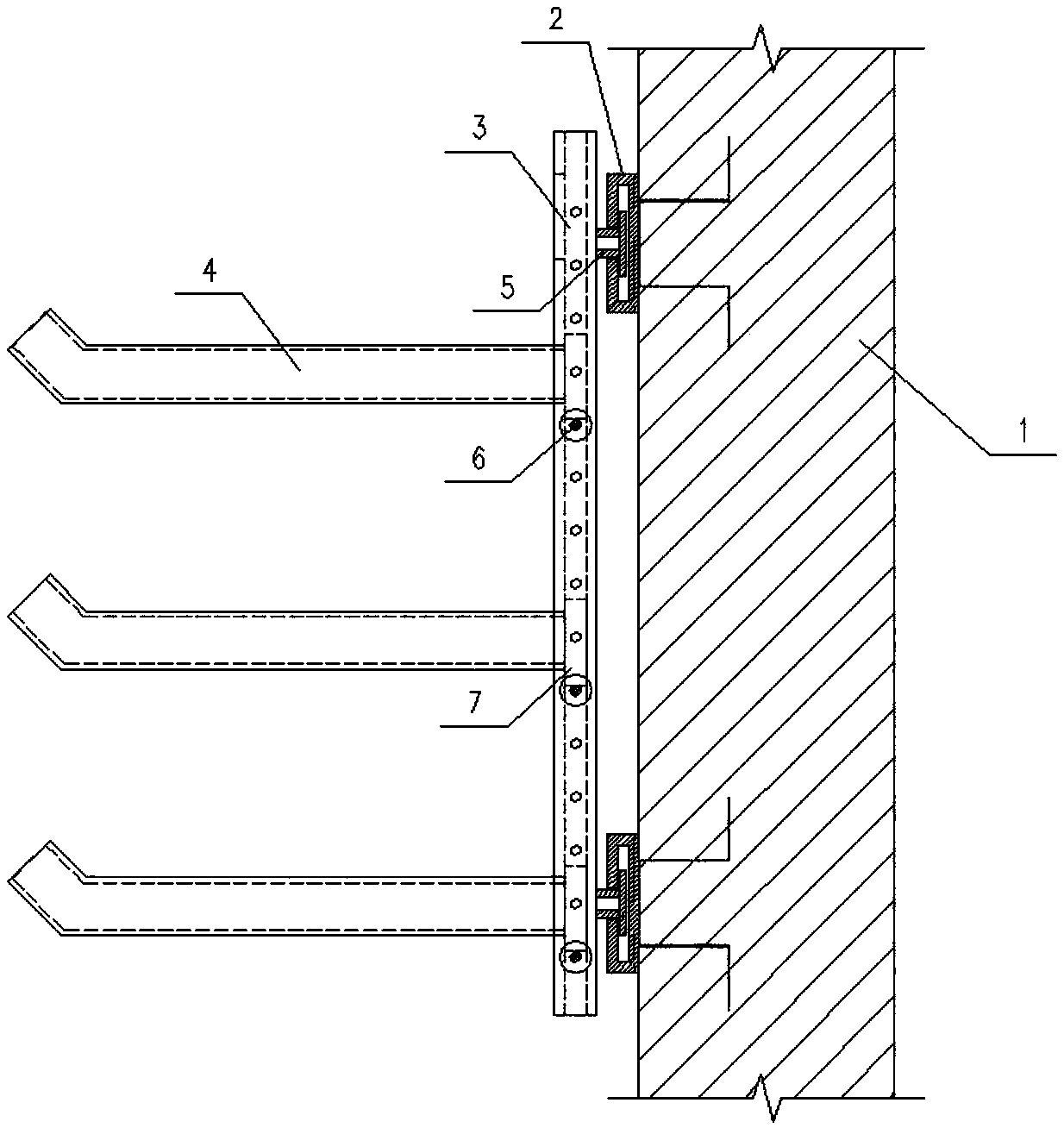

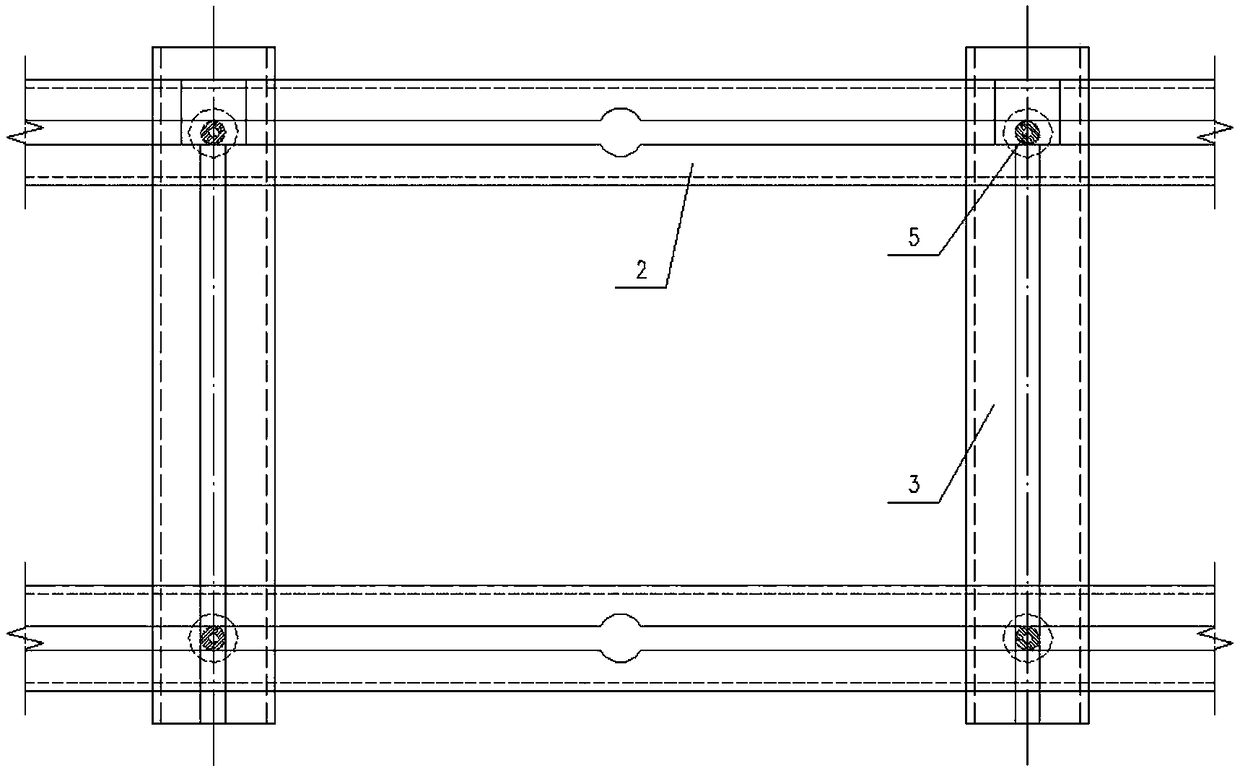

[0018] Such as Figure 1-Figure 5 A two-way adjustable assembled cable support shown includes a pre-embedded part 2 embedded on the side wall of the cable trench 1. The pre-embedded part is provided with a T-shaped groove structure consistent with the cable laying direction of the cable trench. One side of the embedded part with a T-shaped groove structure is set outward, and there are at least two embedded parts, which are arranged in parallel with each other. A column 3 is connected to the embedded part through a T-shaped slot, and the column can be relatively pre-embedded The part reciprocates in the direction of the T-shaped slot of the embedded part, and the T-shaped slot arranged along the direction of the column is arranged on the column, and the trailing arm 4 supporting the cable is also included. One end of the trailing arm is connected to the T-shaped slot of the column. Inside, one end of the trailing arm connected to the T-shaped slot can reciprocate up and down a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com